Selective strong-base anion exchange resin and preparation method thereof

A technology for exchanging resins and anions, which is applied in anion exchange, ion exchange, chemical instruments and methods, etc. It can solve the problems of undiscovered selective strong base anion exchange resins, achieve excellent kinetic performance and selectivity, and simple operation , good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

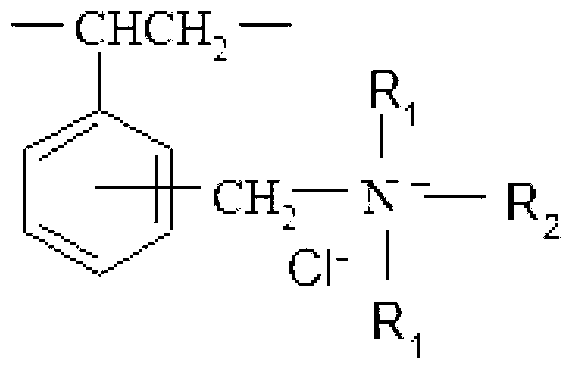

Method used

Image

Examples

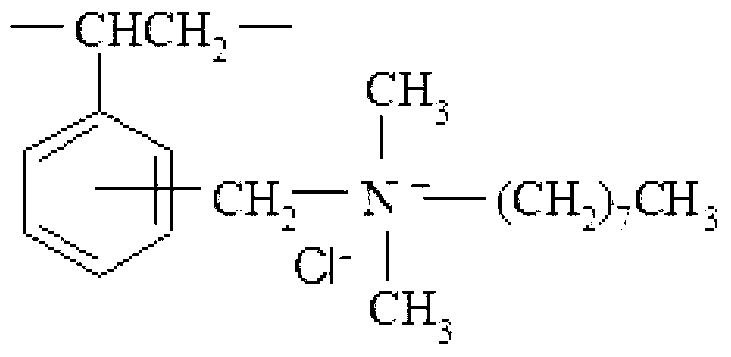

Embodiment 1

[0021] In a 500mL three-neck flask, add 20g of chlorine balls with a cross-linking degree of 8%, add 60g of benzene, and swell at room temperature for 12h; remove the swelling solution, weigh 60g of N,N-dimethyloctylamine and dissolve in 60mL of ethanol-water solution , add dropwise to the flask at room temperature and mix with chlorine balls, and stir while adding; at 40°C, stir and react for 8 hours; filter out the resin, wash with water, dilute hydrochloric acid solution, and water successively, extract with absolute ethanol, and hot air Drying can make strong base exchange capacity be the selective strong base anion exchange resin of 2.86mmol / g, and its structural unit is as follows:

[0022]

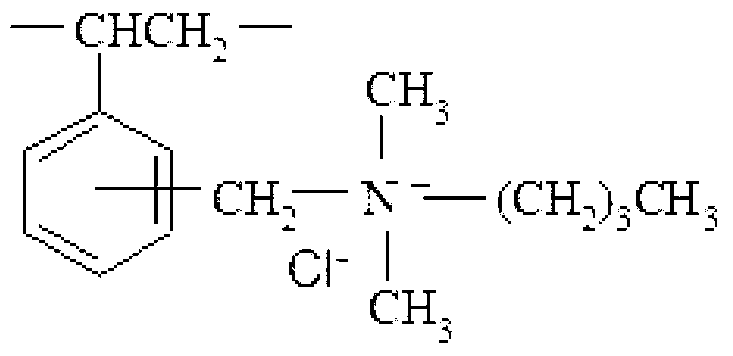

Embodiment 2

[0024] In a 500mL three-neck flask, add 20g of chlorine spheres with a cross-linking degree of 8%, add 60g of nitrobenzene, and swell at room temperature for 12h; remove the swelling solution, weigh 40g of N,N-dimethylbutylamine, dissolve in 40mL of ethanol - In the aqueous solution, add it dropwise to the flask at room temperature and mix with chlorine balls, and stir while adding; at 60°C, stir and react for 10 hours; filter out the resin, wash it with water, dilute hydrochloric acid solution, and water successively, and extract it with absolute ethanol Mention, hot air drying can make strong base exchange capacity be the selective strong base anion exchange resin of 3.57mmol / g, and its structural unit is as follows:

[0025]

Embodiment 3

[0027] In a 500mL three-neck flask, add 10g of chlorine balls with a cross-linking degree of 2%, add 30g of dichloroethane, and swell at room temperature for 24h; remove the swelling solution, weigh 100g of N,N-dimethylpropylamine, dissolve in 100mL of ethanol - into the aqueous solution, drop it into the flask at room temperature and mix it with chlorine balls, and stir while adding it; at 60°C, stir for 24 hours; filter out the resin, wash it with water, dilute hydrochloric acid solution, and water successively, and extract it with absolute ethanol , hot air drying can make a strong base exchange capacity of 4.65mmol / g selective strong base anion exchange resin, its structural unit is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com