Method for preparing graphene and graphene prepared thereby

A graphene and reaction technology, applied in the field of graphene, can solve the problems of growing graphene, etc., achieve the effect of simple operation, promotion of large-scale industrial production, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 (solid source PMMA powder)

[0026] a) Sonicate the copper foil with acetone and deionized water for 3 times, 5 minutes each time.

[0027] b) Put the copper foil into the quartz tube of a tube furnace, heat it to 1000°C, treat it for 30min under the environment of 100sccm hydrogen and 1.8Torr, and slowly cool down to the reaction temperature. Do 5 sets of comparative experiments, the reaction temperatures are 1000°C, 800°C, 700°C, 480°C, 400°C respectively.

[0028] c) Reaction: Heat the solid carbon source PMMA pre-placed at the gas inlet to 200°C. Adjust the hydrogen gas to 50 sccm and the air pressure to 8-15 Torr.

[0029] d) After growing for 45 minutes, stop the heating of the solid-state source and quickly cool down to room temperature.

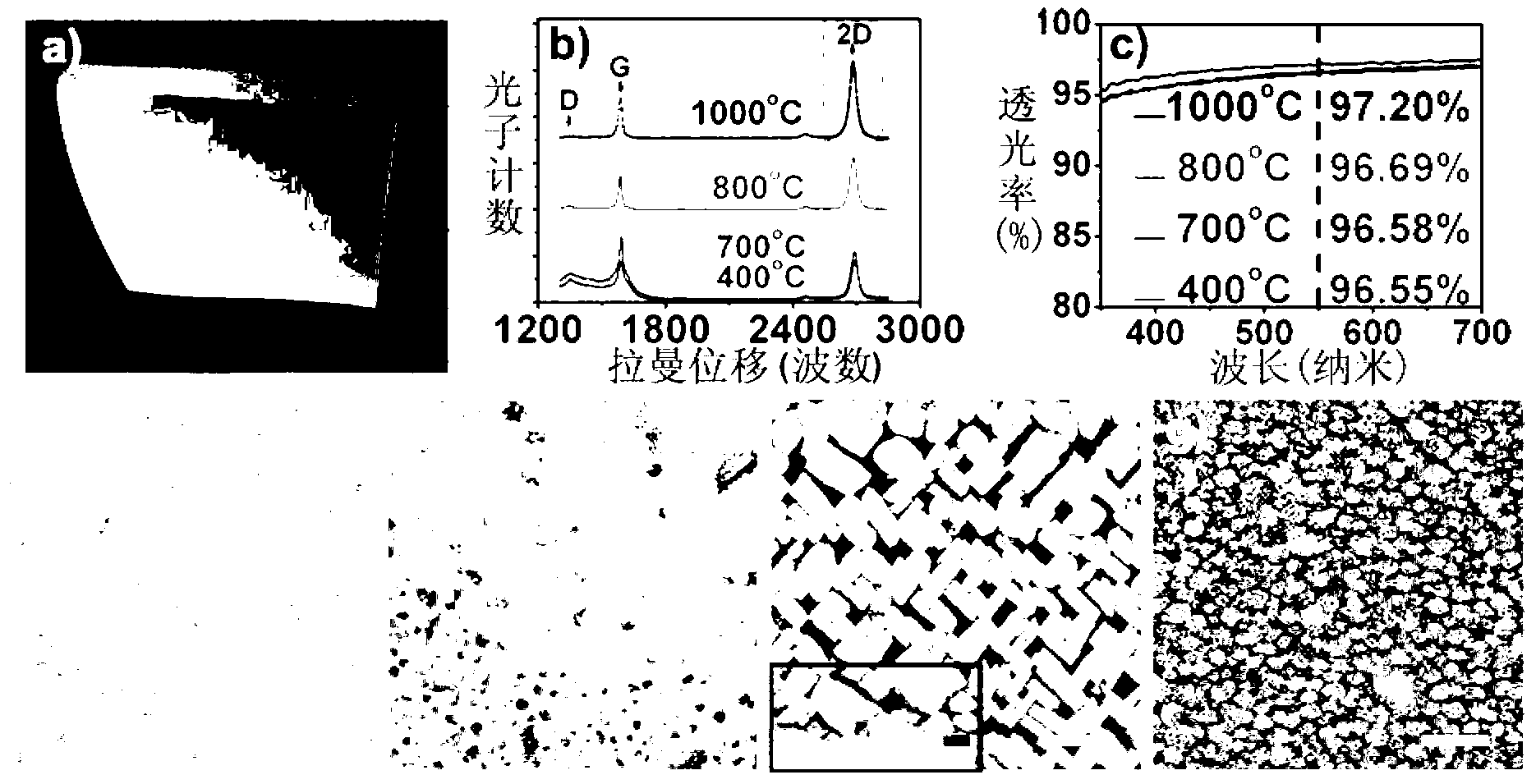

[0030] figure 2 It is the optical photo, Raman signal, light transmittance signal and scanning electron microscope picture of the graphene that embodiment 1 makes. Such as figure 2 As shown in -a, it is an ...

Embodiment 2

[0031] Embodiment 2 (liquid source benzene)

[0032] a) Sonicate the copper foil with acetone and deionized water for 3 times, 5 minutes each time.

[0033] b) Put the copper foil into the quartz tube of the tube furnace, heat it to 1000°C, treat it for 30min under the environment of 100sccm hydrogen and 1.8Torr, and slowly cool down to room temperature.

[0034] c) Reaction: Place the test tube containing benzene at the gas inlet port. Heat the tube furnace to the reaction temperature, and do two sets of comparative experiments, the reaction temperatures are 480°C and 300°C respectively. Adjust the hydrogen gas to 50 sccm and the air pressure to 8-15 Torr.

[0035] d) Grow for 10 minutes to 30 minutes, and quickly cool down to room temperature.

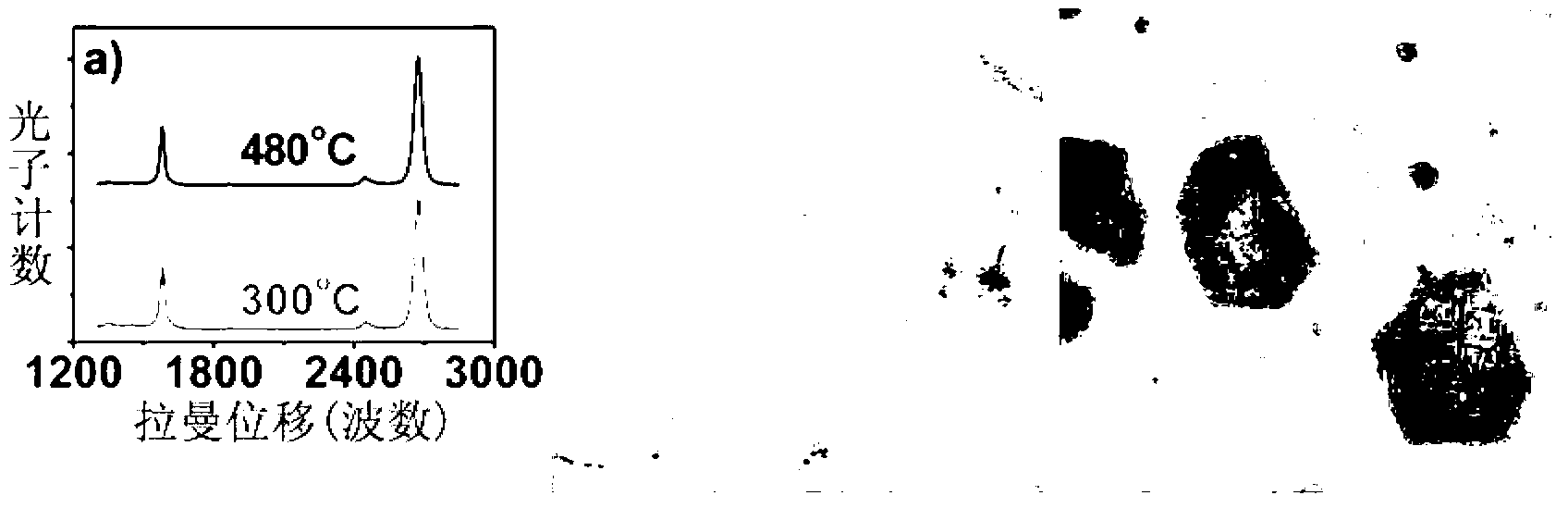

[0036] image 3 It is the Raman signal and the scanning electron microscope picture of the graphene that is made in embodiment 2. Such as image 3As shown in -a, they are the Raman images of graphene obtained at 480°C and 300°C...

Embodiment 3

[0037] Embodiment 3 (solid source p-terphenyl)

[0038] a) Sonicate the copper foil with acetone and deionized water for 3 times, 5 minutes each time.

[0039] b) Put the copper foil into the quartz tube of the tube furnace, heat it to 1000°C, treat it for 30min under the environment of 100sccm hydrogen and 1.8 Torr, and slowly cool down to the reaction temperature of 250°C.

[0040] c) Reaction: Heat the solid carbon source p-terphenyl pre-placed at the gas inlet to 200°C. Adjust the hydrogen gas to 50 sccm and the air pressure to 8-15 Torr.

[0041] d) Grow for 10 minutes to 30 minutes, and quickly cool down to room temperature.

[0042] Figure 4 It is the Raman signal, scanning electron microscope and scanning tunneling microscope picture of the graphene that is made in embodiment 3. Such as Figure 4 As shown in -a, it is the scanning electron microscope picture of the obtained graphene, which can be seen as a continuous single-layer film. The inset is the Raman diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com