Novel derusting material

A metal and aspect technology, applied in the field of rust removal compositions, can solve the problems of excessive corrosion of steel, easy formation of acid mist, and unusable devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

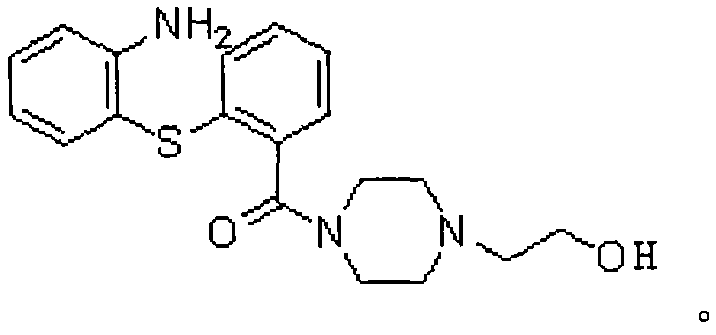

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of 2-(2-nitro-phenylthio)-benzoic acid:

[0028] In a 250 ml three-necked flask, weigh o-chloronitrobenzene (63.4mmol) and 2-mercaptobenzoic acid (62.9mmol), add 110 ml of absolute ethanol, stir, then add potassium hydroxide (138.8mmol), Heating to reflux gradually dissolved the solid. After the reaction (about 8 hours), the reaction solution was cooled to room temperature, and a large number of yellow solids were precipitated. Filter to collect the filter cake. After the filtrate was concentrated, 50 ml of ethyl acetate was added, and a yellow solid precipitated again, which was filtered again. The filter cakes were combined and washed with 100 ml of ethyl acetate. The obtained filter cake was transferred into a 500 ml beaker, 200 ml of water was added, stirred, and the pH value was adjusted to 3-4 with 6N hydrochloric acid, and a yellow solid was precipitated. After filtration, the filter cake was washed twice with water (2×100 ml) and dr...

Embodiment 2

[0030] Example 2: Preparation of (4-(2-(2-hydroxyethoxy)-ethyl))piperazinyl-(2-(2-nitro)phenylthio)-methanone:

[0031]In a 250 ml three-necked flask, weigh 2-(2-nitro-phenylthio)-benzoic acid (36.3 mmol), add 120 ml of toluene, stir, slowly add thionyl chloride (12 ml, 164.4mmol), after the addition was completed, the reaction was refluxed for 12 hours (TLC monitored the reaction). After the reaction was completed, it was cooled to room temperature, and toluene and excess thionyl chloride were distilled off under reduced pressure. Another 200 ml of toluene was added to obtain a toluene solution of the acid chloride. The toluene solution of the resulting acid chloride was transferred to another 500 ml three-necked flask, stirred, and under cooling in an ice-water bath, triethylamine (8 ml, 57.4 mmol) was added dropwise. 1-[2-(2-Hydroxyethyl)piperazine (36.3mmol) was added. After the reaction was incubated for 30 minutes, the reaction was stirred at room temperature for 8 hou...

Embodiment 3

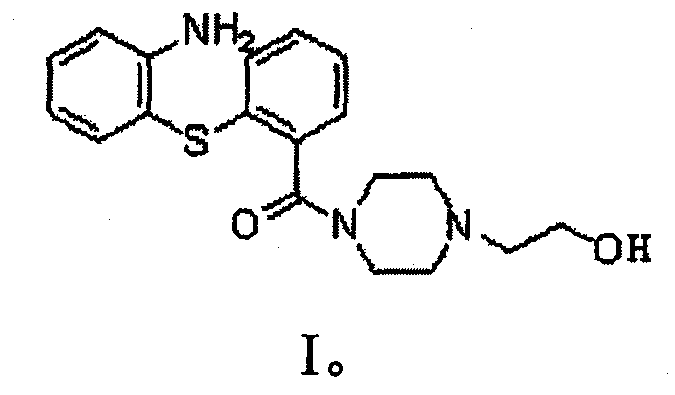

[0033] Embodiment 3: the preparation of formula I compound crystal:

[0034] Accurately weigh the compound of formula I obtained above, put it into an agate grinding body and grind it thoroughly, and then put the sample into a platinum crucible. Put it into a box furnace at 90°C for pre-sintering and grinding. Finally, keep the temperature at 150°C for 6 hours, and slowly cool to room temperature in stages (first stage: drop to 100°C at a rate of 2°C / h; second stage: drop from 100°C to room temperature at a rate of 10°C / h ). Finally, white powdery crystals were obtained at the bottom of the crucible. Carry out single crystal X-ray diffraction crystallography to this crystal and analyze its crystal structure, and its crystallographic parameter is, described crystal belongs to monoclinic crystal system, and its space group is P21, β=91.2°,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com