A kind of production equipment and production method of mesobiotics raw powder

A production method and technology of production equipment, applied in the field of production equipment of zhongshengmycin raw powder, can solve the problems of zhongshengmycin biological activity damage loss, serious material liquid loss, unformed filter cake, etc., and achieve product damage loss Less, mild process conditions, less artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

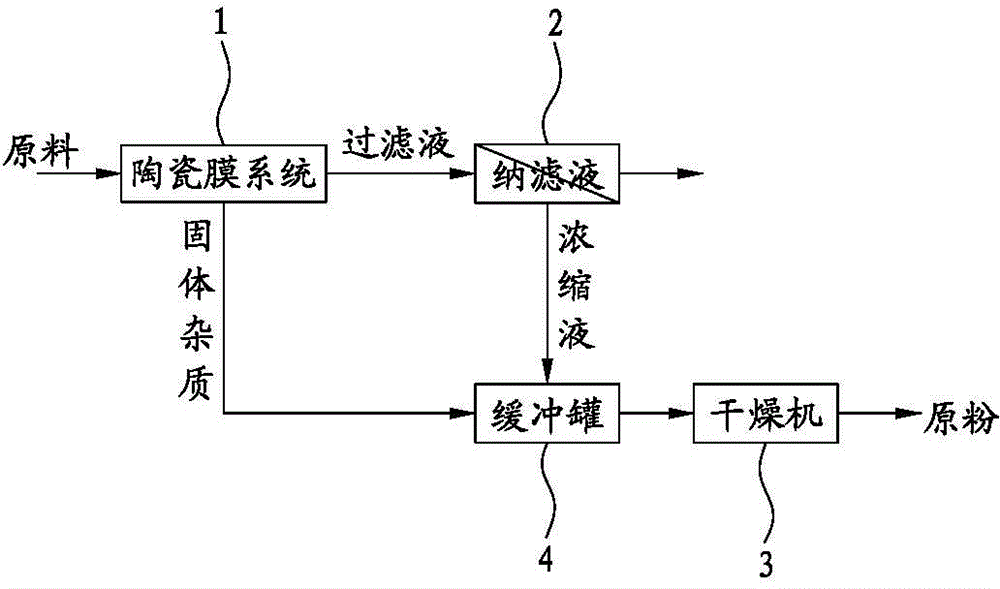

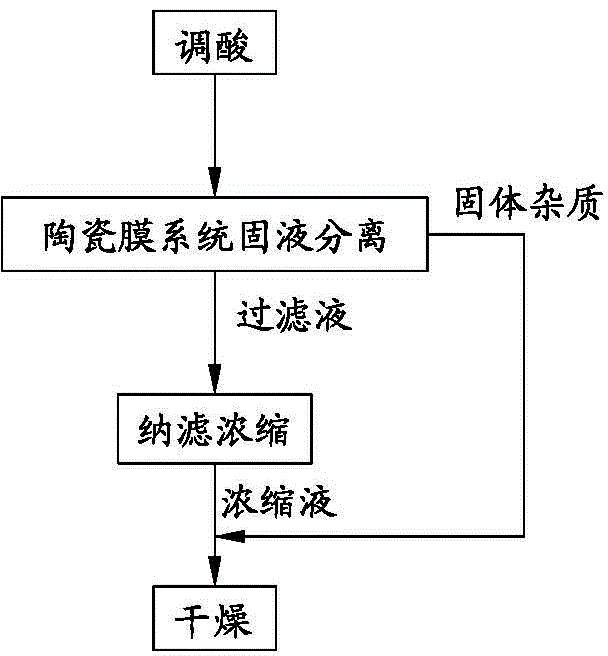

Method used

Image

Examples

Embodiment 1

[0041] Use 1000L of fermented liquid containing Zhongshengmycin with a concentration of 8.5g / L as the raw material, adjust the pH to 4.0; use a ceramic membrane with a pore size of 0.1um at room temperature, operate at a pressure of 0.25Mpa, add 2000L of acidic water for membrane filtration and dialysis and maintain pH4.0; the filtrate directly enters the nanofiltration system with a cutting molecular weight of 400Da for concentration, and the operating pressure is 2.0Mpa to obtain a concentrated solution of 100L. The potency of the concentrated solution is 77.5g / L. The total yield from the fermentation broth to the concentrated solution is: 91.18%; the concentrated solution was spray-dried to obtain 18.3kg of Zhongshengmycin raw powder, with a potency of 403,800 u / g, a spray yield of 95.35%, and a total product yield of 86.94%.

Embodiment 2

[0043]Use 1000L of fermented liquid containing Zhongshengmycin with a concentration of 9.6g / L as raw material, adjust the pH to 4.0; use a ceramic membrane with a pore size of 0.05um at room temperature, operate at a pressure of 0.3Mpa, add 2000L of acidic water for membrane filtration and dialysis and maintain pH4.0; the filtrate directly enters the nanofiltration system with a cutting molecular weight of 400Da for concentration, the operating pressure is 2.2Mpa, and 98L of concentration is obtained, the potency of the concentrate is 90.6g / L, and the total yield from the fermentation broth to the concentrate is: 92.49 %; the concentrated solution was spray-dried to obtain 18.7kg of Zhongshengmycin powder, with a potency of 455,800 u / g, and a spray yield of 96.00%; the total yield of the product was 88.79%.

Embodiment 3

[0045] Using 1000L of fermented liquid containing Zhongshengmycin with a concentration of 9.2g / L as raw material, adjust the pH to 4.0; use a ceramic membrane with a pore size of 0.1um at room temperature, operate at a pressure of 0.3Mpa, add 2000L of acidic water for membrane filtration and dialysis and maintain pH4.0; the filtrate directly enters the nanofiltration system with a cutting molecular weight of 400Da for concentration, and the operating pressure is 2.3Mpa to obtain a concentrated solution of 105L. The potency of the concentrated solution is 81.5g / L. The total yield from the fermentation broth to the concentrated solution is: 93.02%; the concentrated solution was spray-dried to obtain 17.5kg of Zhongshengmycin raw powder, the potency was 467,000 u / g, the spray yield: 95.50%; the total product yield: 88.83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com