Preparation method of three-dimensional penetrating anode aluminum oxide template

A technology of anodized aluminum and aluminum oxide templates, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problem of tubular structure that only pays attention to the order of pores and upper and lower penetration, and ignores the application value of three-dimensional penetration templates, etc. problem, to achieve the effect of good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

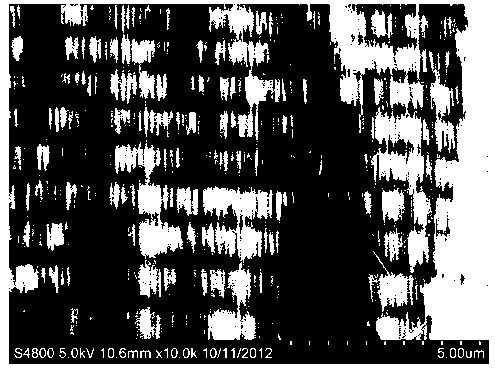

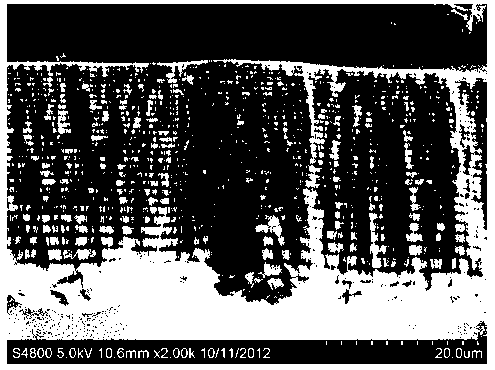

Image

Examples

Embodiment 1

[0024] (1) First, cut the high-purity aluminum sheet (Al, 99.999%) into a disc with a diameter of 20mm and a thickness of 0.2mm, and soak it in a mixed solution of acetone and ethanol (volume ratio 1:1) to remove the surface of the aluminum sheet. Dirt, then put the aluminum sheet in a tube vacuum furnace at 550 degrees Celsius for 6 hours to eliminate the stress in the aluminum sheet. The annealed aluminum sheet is immersed in a mixed acid solution of 75% phosphoric acid and 65% nitric acid (volume ratio of phosphoric acid, concentrated nitric acid and double distilled water 8: 1:1), and chemically polished to obtain a bright and smooth surface Aluminum sheet.

[0025] (2) Using the aluminum sheet processed in step (1) as the anode and the copper sheet as the cathode, the polished aluminum sheet is subjected to a staged variable pressure cycle treatment to obtain an alumina template with irregular pore diameters. Boost from 40 volts to 70 volts at a rate of 1 volt per minute, a...

Embodiment 2

[0029] (1) First cut the high-purity aluminum sheet (Al, 99.999%) into a disc with a diameter of 20 mm and a thickness of 0.2 mm, and soak it in a mixed solution of acetone and ethanol (volume ratio 1:1) to remove the aluminum sheet Then put the aluminum sheet in a tube vacuum furnace at 530 degrees Celsius for 8 hours to eliminate the stress in the aluminum sheet. The annealed aluminum sheet is immersed in a mixed acid solution of 65% by mass phosphoric acid and 65% by mass nitric acid (the volume ratio of phosphoric acid, concentrated nitric acid and double distilled water is 8: 1:1), and chemically polished to obtain a bright and smooth surface Aluminum sheet.

[0030] (2) Using the aluminum sheet processed in step (1) as the anode and the copper sheet as the cathode, the polished aluminum sheet is subjected to a staged variable pressure cycle treatment to obtain an alumina template with irregular pore diameters. Boost from 40 volts to 65 volts at a rate of 2 volts per minute...

Embodiment 3

[0034] (1) First cut the high-purity aluminum sheet (Al, 99.999%) into a disc with a diameter of 20 mm and a thickness of 0.2 mm, and soak it in a mixed solution of acetone and ethanol (volume ratio 1:1) to remove the aluminum sheet Then put the aluminum sheet into a tube vacuum furnace at 500 degrees Celsius for 12 hours to eliminate the stress in the aluminum sheet. The annealed aluminum sheet is immersed in a mixed acid solution of 80% phosphoric acid and 65% nitric acid (volume ratio of phosphoric acid, concentrated nitric acid and double distilled water 8: 1:1), and chemically polished to obtain a bright and smooth surface Aluminum sheet.

[0035] (2) Using the aluminum sheet processed in step (1) as the anode and the copper sheet as the cathode, the polished aluminum sheet is subjected to a staged variable pressure cycle treatment to obtain an alumina template with irregular pore diameters. Boost from 40 volts to 75 volts at a rate of 1 volt per minute, then stabilize at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com