Inorganic fireproof building heat preservation system and construction method thereof

A technology for fire-resistant buildings and thermal insulation systems, applied in thermal insulation, buildings, building components, etc., can solve the problem of less than 0.5Mpa, or even only 0.1Mpa, reduce the service life of the external wall thermal insulation system of the house, and the low compressive strength of the external wall thermal insulation system, etc. problems, to achieve the effect of low cost, good thermal insulation effect and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

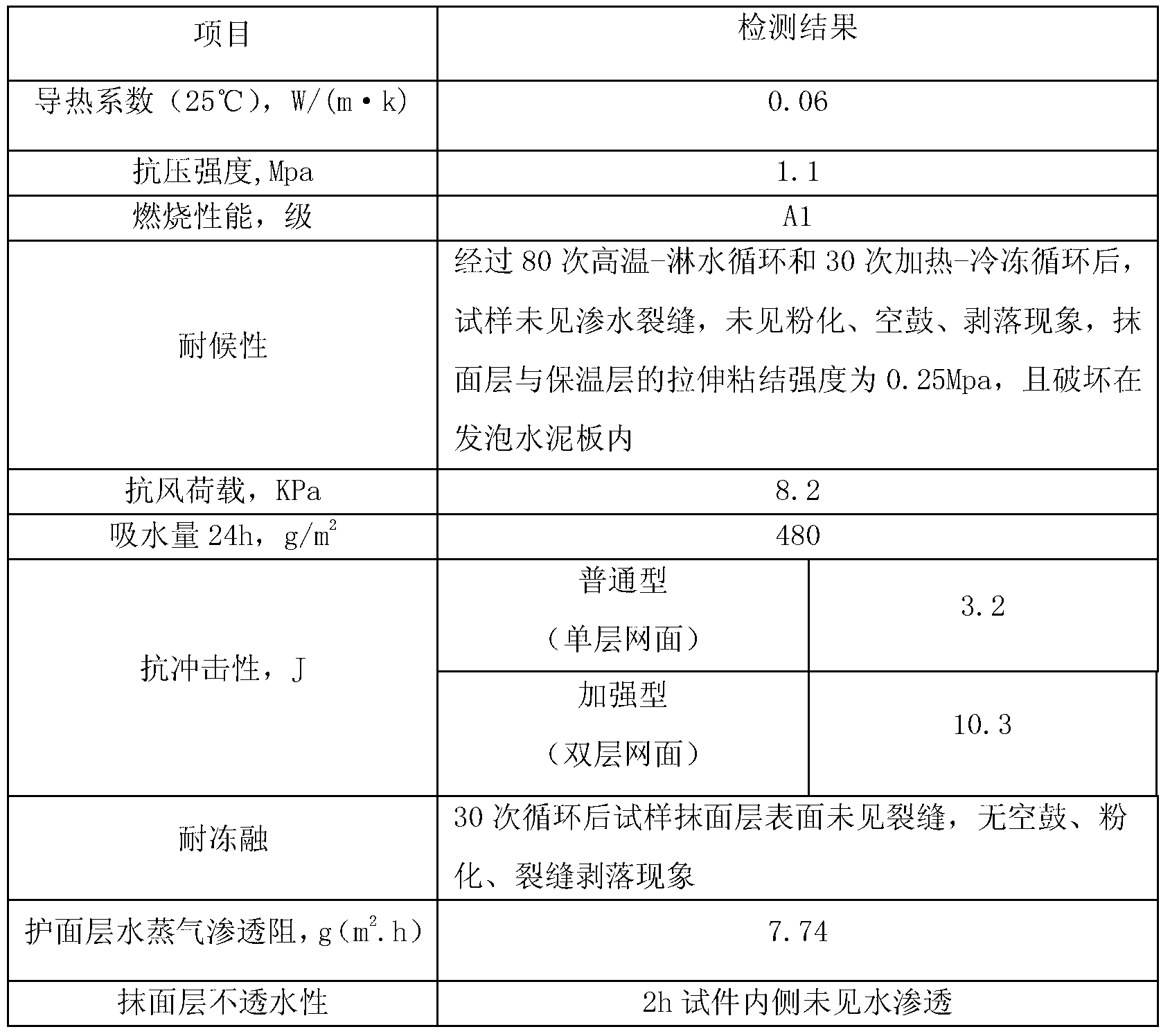

Examples

Embodiment

[0027] (1) Pretreatment of the wall:

[0028] Remove water stains, oil stains and other attachments on the wall surface, dry (the water content of the wall surface is <8%), remove the raised, hollow and loose parts of the wall, and the deviation of the flatness of the wall surface is less than 4mm.

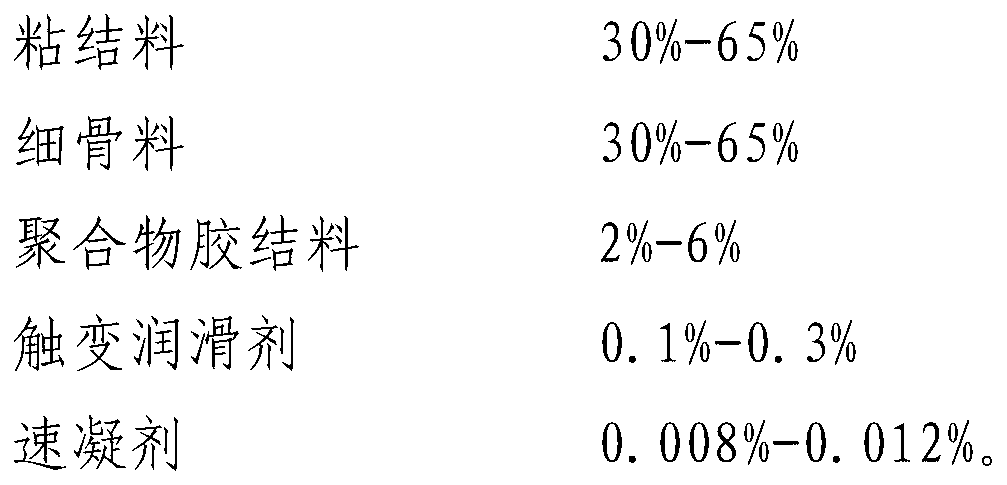

[0029] (2) Preparation of bonding mortar:

[0030] Mix the following raw materials according to the added amount (parts by weight), specifically:

[0031] 360 parts of ordinary cement (PO42.5 Portland cement), 19 parts of high alumina cement, 580 parts of graded yellow sand (70-140 mesh), 39 parts of polymer cement (including dispersible latex powder, hydroxypropyl methyl The weight ratio of cellulose ether (30,000 viscosity) to silicone water repellent is 45:3:2), 1.9 parts of thixotropic lubricant and 0.1 part of lithium chloride are added to a gravity-free mixer and mixed for 5 minutes. Adhesive mortar.

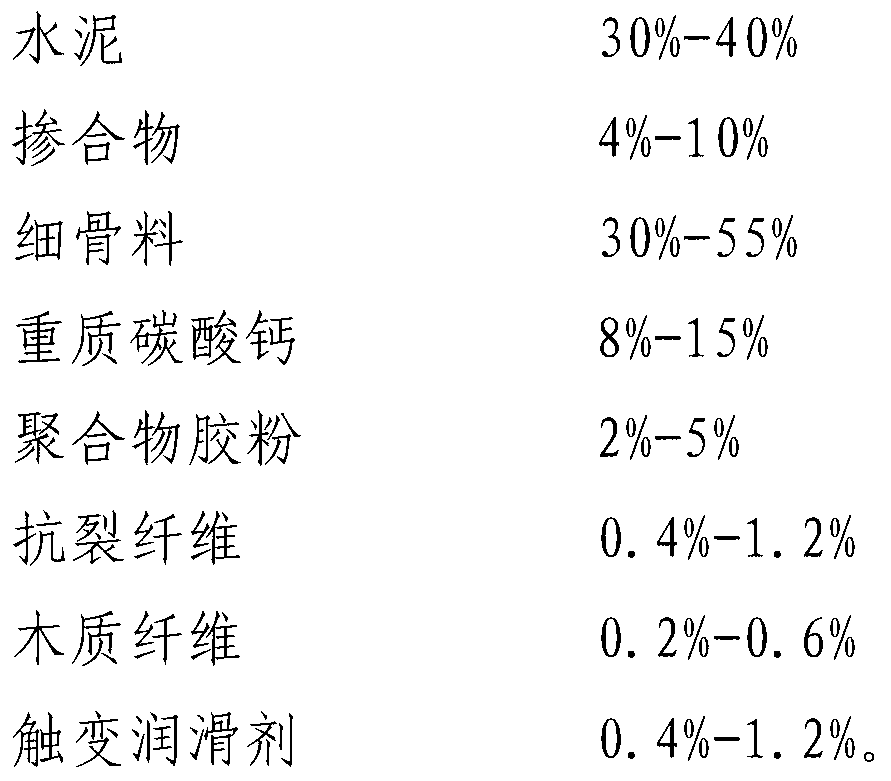

[0032] (3) Preparation of plastering anti-cracking mortar:

[0033] M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com