Method of cooling gas turbine blades

A technology for gas turbine blades and turbine blades, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems of weak lifting effect of cooling turbine blades, reducing the heat capacity of cooling gas, and affecting the performance of gas turbines. The effect of simplifying the structure, increasing the shaft power and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principle, specific implementation and working process of the present invention will be further described below in conjunction with the accompanying drawings.

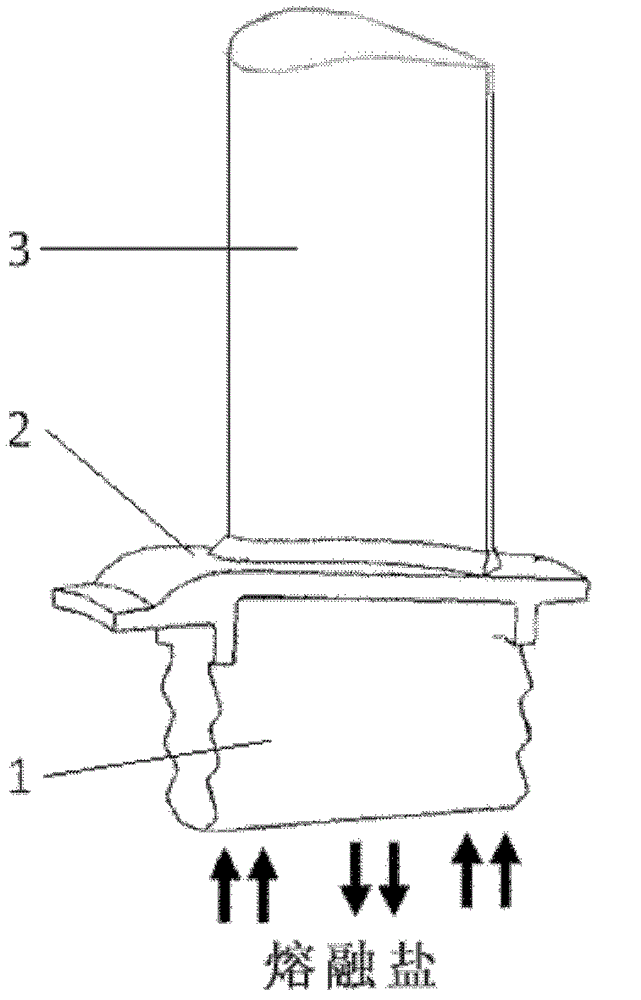

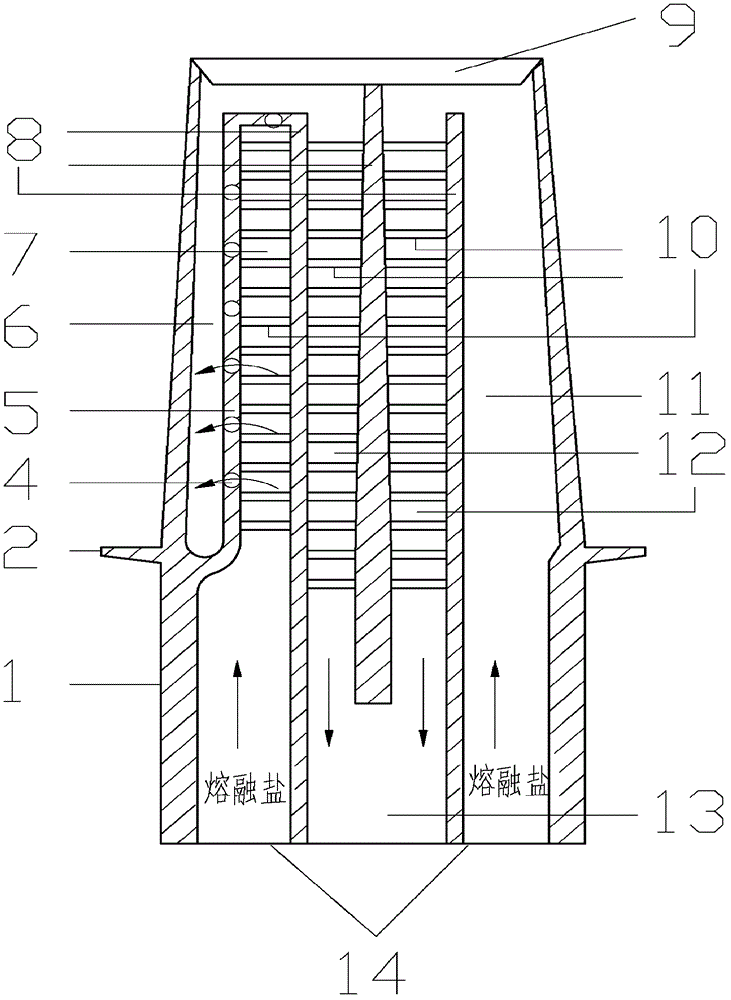

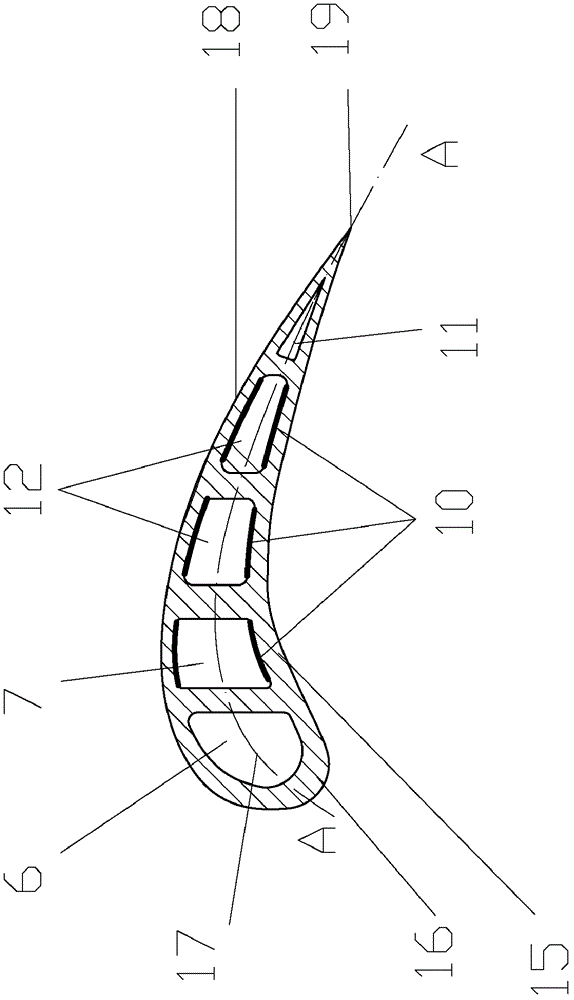

[0022] Accompanying drawing has provided a specific embodiment of the present invention, figure 1 It is a three-dimensional view of a high-temperature turbine blade of a gas turbine, which includes a blade profile 3, a blade heel 1, and a blade platform 2 connecting the two. Cutting the blade along the central arc 17 of the blade, the internal structure of the blade can be obtained such as figure 2 shown. There are multiple cooling passages 6, 7, 11, 12 for cooling the flow of molten salt inside the blade, and molten salt (such as mixed molten salt composed of 40% potassium nitrate and 60% sodium nitrate by mass percentage) is fed by the blade root cooling passage inlet 14 It enters the internal cooling passages 6 and 11 of the blade, flows through the internal cooling passages 7 and 12 respectively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com