Composite sensors and methods for bioprocess diagnostics and material characterization

A composite sensor and biological process technology, applied in the field of biological process diagnosis, can solve problems such as single, inflexible feedback, and signal lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

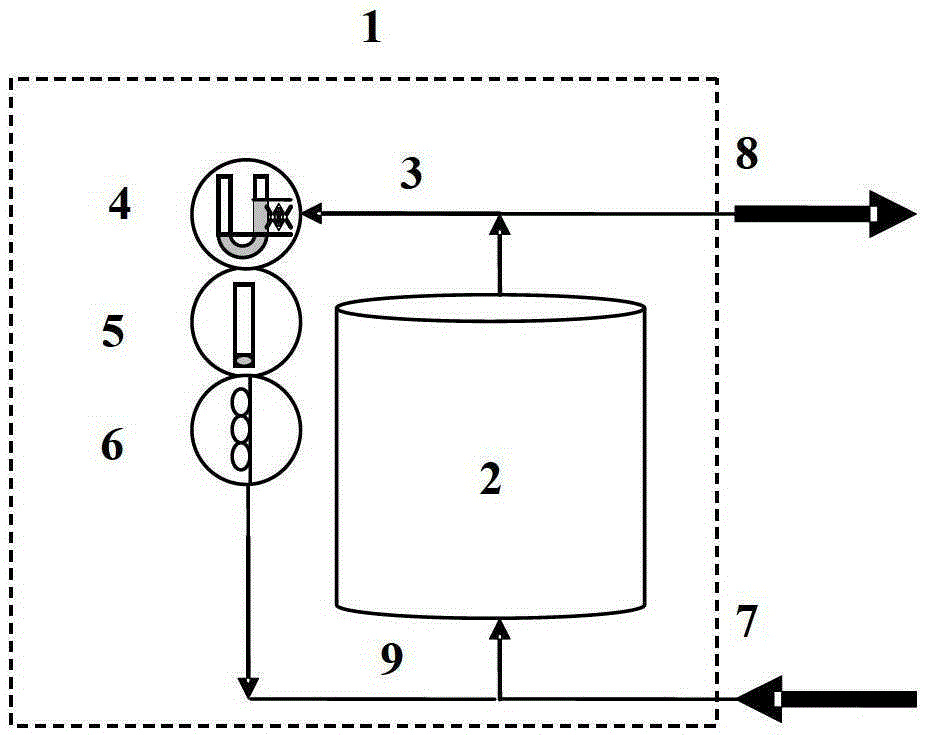

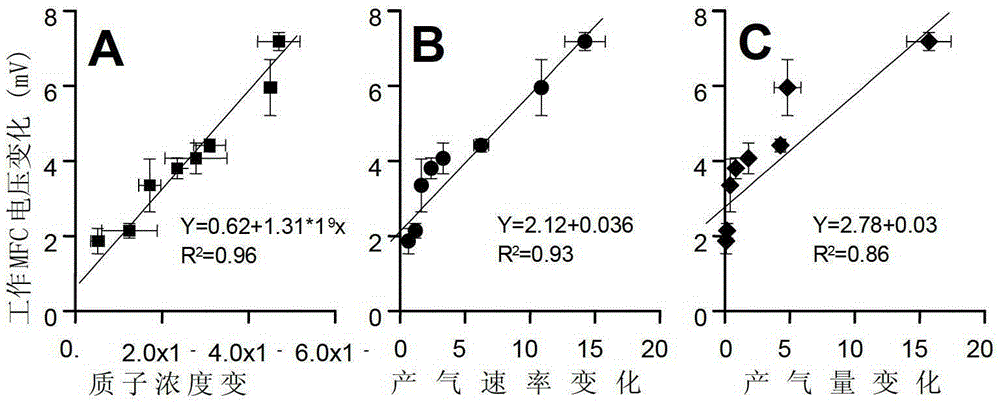

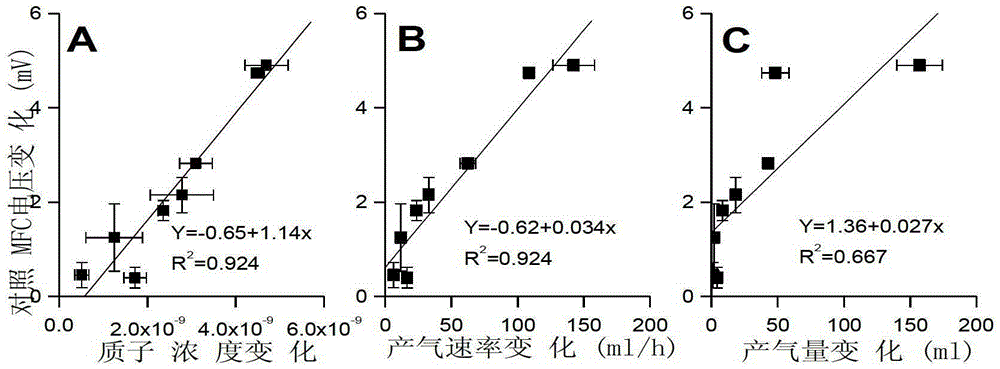

[0044] For the structure diagram of the composite sensor, please refer to figure 1 . Firstly, under the baseline condition of organic loading rate of 1gCOD / L / d in the packed bed reactor, the signal relationship of the three sensors of MFC, pH meter and gas flow meter was compared online through the signal fluctuation caused by pulse injection. Increase the pulse matrix concentration (mixed concentration 0 ~ 500mgCOD / L), the voltage signal change (ΔU), gas flow rate change (ΔgFR) and gas cumulative volume change (ΔgV) of the MFC increase accordingly, and the pH change (ΔpH) increases accordingly decrease. The relationship between ΔU and substrate concentration can be described by the Monod equation. According to the equation, the biofilm MFC (BiofilmMFC, which has electrochemically active biofilm adsorption from the anode) has a higher saturation value than the control MFC (ControlMFC), that is, it has a wider concentration detection space. In order to further compare the re...

Embodiment 2

[0047] Using the device in Example 1, sodium acetate is used as a pulse matrix to inject samples to investigate the changes of different process variables, mainly including the output voltage, pH, gas flow rate, gas production rate, external circulation liquid SCOD, acetic acid, propionic acid and total of MFC. VFAs. Online data are based on the average of three repeated pulse injections, and offline parameter analysis is also based on the average of three repeated pulse injections. All injections are based on continuous operation of 1gCOD / L / dOECD to provide sufficient buffer capacity and stable microbial metabolic activity for the biogas fermentation system. Figure 4 It is the change of various parameters when injecting sodium acetate with a volume of 1mL and a concentration of 200g / L. MFC produces obvious voltage peaks, which are consistent with gas flow convex peaks and pH concave peaks. In addition, off-line VFAs analysis is especially for acetic acid in the filtrate The...

Embodiment 3

[0049] Sodium acetate and cellulose injection:

[0050] Using the device in Example 1, sodium acetate is used as a pulse matrix to inject samples to investigate the changes of different process variables, mainly including the output voltage, pH, gas flow rate, gas production rate, external circulation liquid SCOD, acetic acid, propionic acid and total of MFC. VFAs. Online data are based on the average of three repeated pulse injections, and offline parameter analysis is also based on the average of three repeated pulse injections. All injections are based on continuous operation of 1gCOD / L / dOECD to provide sufficient buffer capacity and stable microbial metabolic activity for the biogas fermentation system. Image 6 is the change of each parameter when injecting a mixture of sodium acetate and cellulose with a volume of 1mL. The concentrations of sodium acetate and cellulose in the mixture are both 200g / L, which is similar to the case of injecting only sodium acetate, indicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com