Active lactobacillus beverage preparation method and active lactobacillus beverage prepared therethrough

A technology of active lactic acid bacteria and fermented milk products, which is applied in the field of food processing, can solve the problems of easy stratification, decline, and unstable product quality, etc., to facilitate proliferation, increase the degree of decomposition of milk protein, and overcome poor decomposition ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of reconstituted milk (12% reconstituted milk): skimmed milk powder (purchased from New Zealand Fonterra Group with a protein content of 34% by mass) and water were prepared at a mass ratio of 1:7 to prepare reconstituted milk.

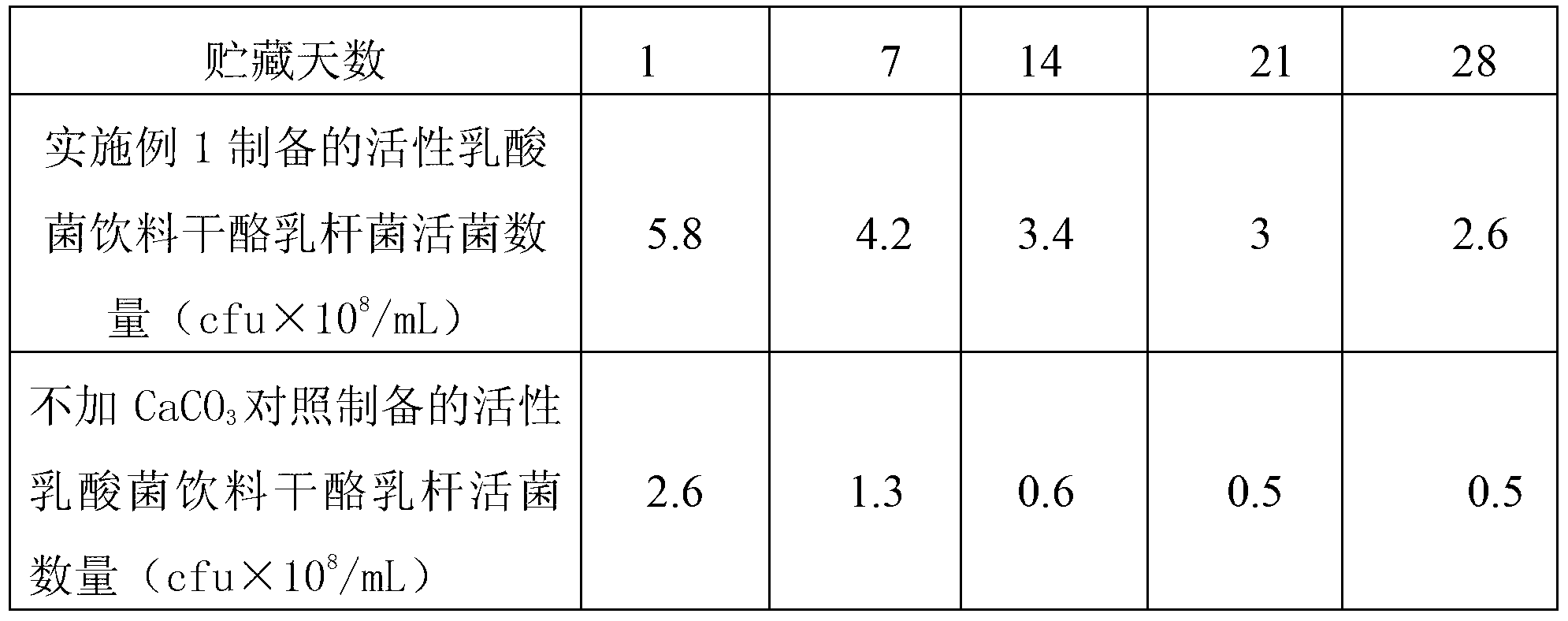

[0035] The obtained reconstituted milk was preheated to 60°C for sterilization, homogenized at 20MPa; sterilized at 95°C for 120 minutes; cooled to 32°C, inoculated with Lactobacillus casei 10 6 cfu / mL, add aseptic particulate calcium carbonate at 0.5% by mass, the original average particle size is 5 μm, heat preservation and fermentation at 32°C for 72 hours, turn over the tank, and then cool to 15°C to obtain fermented milk base material; Add 12% of the mass percentage of fermented milk base material and mix it with water, then sterilize (95°C, 5min), cool to 15°C, mix water and fermented milk base material with the obtained fermented milk base material according to the volume ratio of 75:25, Homogenize at 32°C with a homogenizati...

Embodiment 2

[0038] Preheat fresh skim milk (3.4% protein by mass percentage) to 65°C, homogenize at 20MPa; sterilize at 90°C for 30 minutes; cool to 30°C, inoculate with Lactobacillus casei 10 6 cfu / mL, Streptococcus thermophilus 10 6 cfu / mL, according to the mass percentage content of 0.01%, add aseptic micro-powder calcium carbonate, the original average particle size is 1-5μm, turn over the tank for 48 hours of fermentation at 28°C, and then cool to 20°C to obtain the fermented milk base material; Glucose The slurry is mixed with water in an amount of 12% by mass of the fermented milk base material, sterilized (90°C, 5min), cooled to 10°C, and mixed with the above pre-fermented milk base material according to the volume ratio of water to fermented milk base material 90:10 Mix, homogenize at 20MPa, fill at 20°C; then store in cold storage (4-10°C).

[0039] The shelf life of the fermented milk-containing beverage containing active probiotics is 30 days when stored at 4-10°C. Lactobaci...

Embodiment 3

[0041] Preheat fresh milk (3.0% protein mass percentage, 3.1% fat mass percentage content) to 60°C, homogenize at 20MPa; sterilize at 90°C for 90min; cool to 30°C, inoculate Lactobacillus casei for 10 6 cfu / mL, add aseptic ultrafine calcium carbonate at 1% by mass, the original average particle size is 0.02-0.1 μm, heat-preserve and ferment at 28°C for 64 hours, turn over the tank, and then cool to 10°C to obtain the fermented milk base; Mix aspartame with water at a mass percentage of 0.06% of the milk base, sterilize (95°C, 5min), cool to 20°C, and mix with the above-mentioned fermented milk according to the volume ratio of water to fermented milk base material 40:60 The base material is mixed, homogenized at 37°C and 20MPa, filled at 20°C; then stored in a cold storage (4-10°C).

[0042] The shelf life of the fermented milk-containing beverage containing active probiotics is 30 days when stored at 4-10°C. Lactobacillus casei at the initial stage of storage was greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com