Preparation method of three-dimensional metal mesh with preferential adsorption/separation performance

A separation performance, metal mesh technology, applied in separation methods, adsorption water/sewage treatment, liquid separation, etc., can solve the problems of high preparation cost, poor selectivity, low adsorption capacity, etc., and achieve simple preparation process route and reusability. Good, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The present invention is a preparation method of a three-dimensional metal mesh with selective adsorption / separation performance, and its steps are:

[0011] (1) The nano-sheet thickness of graphene is coated on the metal grid by the dipping method to construct micro-nano-scale surface roughness, and then the low surface energy substance is coated on the graphene surface by the dipping method. Change its surface chemical energy to construct a two-dimensional metal grid with super-hydrophobic and super-lipophilic properties with a surface water contact angle of 150-155 degrees and an oil contact angle of 0 degrees;

[0012] (2) Lap at least two two-dimensional metal grids at an angle to form a three-dimensional three-dimensional metal grid.

[0013] According to the above In the method, graphene with a thickness of nano-sheets is coated on a metal grid by a dipping method to construct a micro-nano-scale surface roughness. The thickness of the graphene sheet is between 0.8-2 na...

Embodiment 1

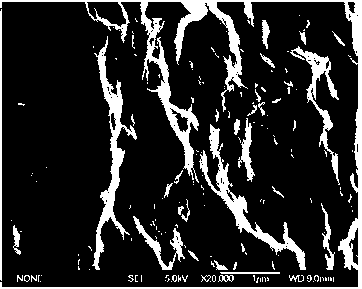

[0020] Dissolve 30mg of graphite oxide in 10mL of distilled water and disperse ultrasonically for 30 minutes to prepare a 3mg / mL graphene oxide aqueous solution. According to the volume ratio of organic phase to water of 9:1, add 90mL of nitrogen and nitrogen-dimethylformamide to make 0.3mg / mL graphene oxide solution. Add 30 μL of hydrazine hydrate and react at 80° C. for 1 hour to obtain a graphene impregnation solution. A metal grid with a mesh size of 400 is selected as the substrate, immersed and dried at 80°C, and the graphene sheets are attached to the metal grid. Subsequently, the graphene-attached metal mesh was immersed in a 1 mg / ml polydimethylsiloxane toluene solution, and dried at 80°C for 12 hours to obtain a two-dimensional metal mesh with super hydrophobic and super lipophilic properties. Its SEM photo is like figure 1 As shown in the figure, it can be seen that the surface of the prepared two-dimensional metal mesh is attached with layered graphene to form a ...

Embodiment 2

[0022] The super-hydrophobic and super-lipophilic two-dimensional metal mesh obtained in Example 1 is made into a cubic or columnar metal mesh adsorption material by mechanical processing means. Figure 2~Figure 5 Shows the process diagram of the selective adsorption of organic matter in water by the cubic metal mesh. Image 6 Shows the dynamic selective adsorption diagram of the columnar metal mesh for organics in water. Figure 7 Shows the amount of adsorption of organic matter in water by the cubic metal mesh. Picture 8 Based on the surface water contact angle, it shows the repeatability of the cubic metal mesh in the application.

[0023] The contact angle of water on the surface of the superhydrophobic metal mesh prepared by the invention is 152 degrees, and the contact angle of oil is 6.7 degrees. It has selective adsorption capacity for oil and non-polar solvents in water (only oil or non-polar solvents are adsorbed, It does not absorb water) and has good reusability. It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com