Preparation method of feed tannalbin and tannalbin prepared by method

A technology of tannin protein and gallnut, applied in animal protein processing, application, animal feed, etc., can solve problems such as reducing the environmental protection burden of gallnut processing enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 (continuous wall breaking, CB)

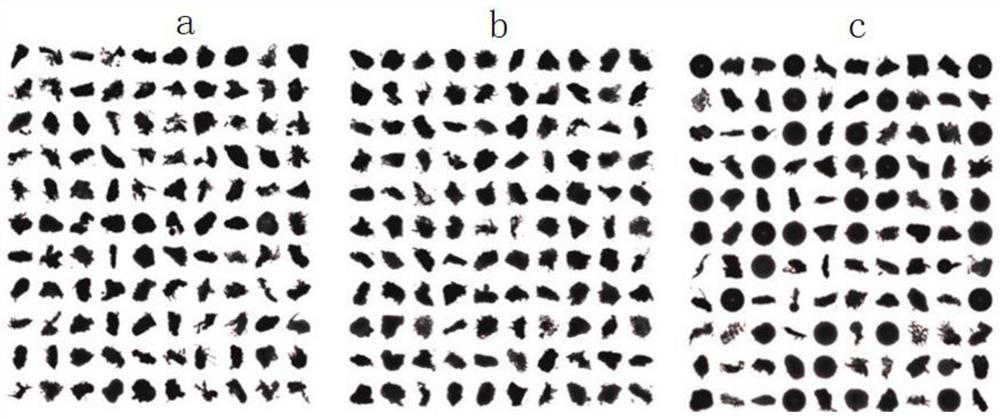

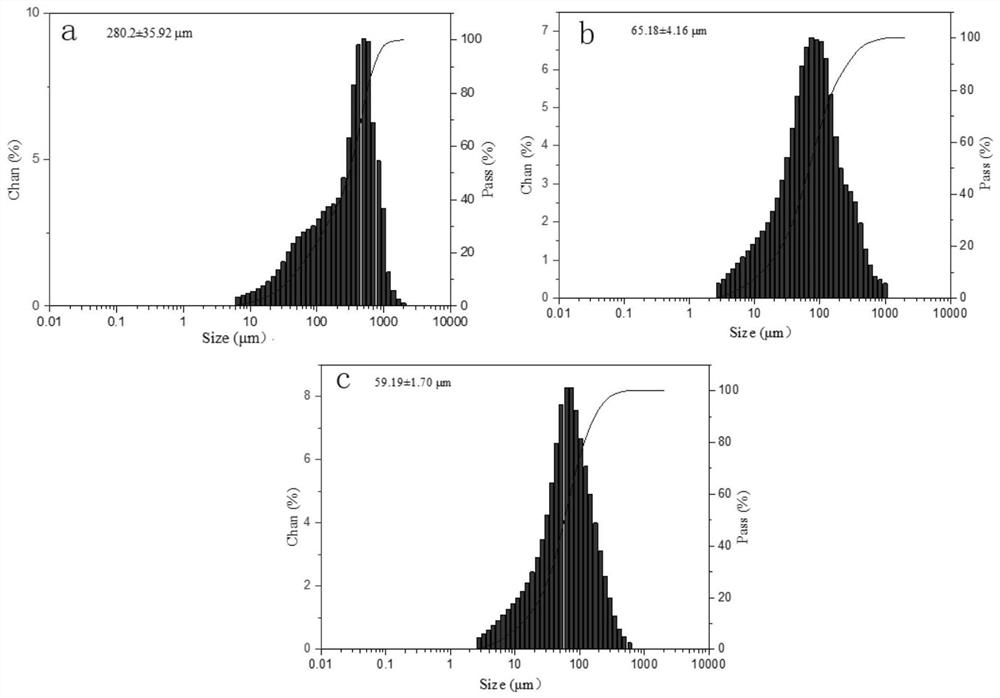

[0061] 1. Superfine pulverization treatment

[0062] Add 20g of the sieve to 200mL of water, wherein the ratio of the mass of gallbladder sieve to the volume of water is 1:10 (m / v, usually 1:(8-12)), put it in a broken wall cooking machine, Carry out superfine pulverization processing, and processing time is 3min (being generally 2-5min); The power of broken wall cooking machine is 1500W (being generally 1500-2000W), and the rotating speed is 20000rpm (being generally 15000-25000rpm), and the Galla gall homogenate ( 220mL), wherein, the particle size of the Galla gall sieve powder in the Galla gall homogenate is 60-100 μm, for subsequent use;

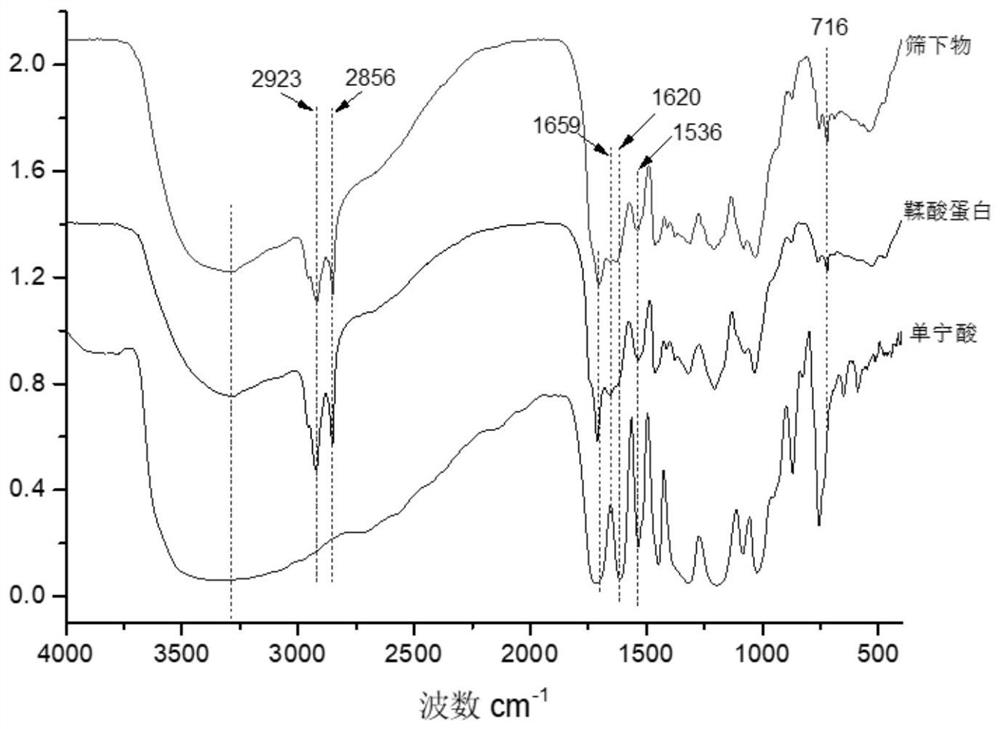

[0063] The ultra-fine pulverization process is to crush the dried gallworm body, destroy the chitin on the surface of the gallworm body, and let the insect body tissue be displayed, especially the protein of the gallnut aphid; Among them, tannins are dissolved.

[0064] 2. Ultrason...

Embodiment 1A

[0079] Embodiment 1A (continuous wall breaking, CB)

[0080] 1. Superfine pulverization treatment

[0081] In addition to adding 20g gallnut sieve sieve into 240mL water, the ratio of the quality of gallnut sieve sieve to the volume of water is 1:12 (m / v), and the ultrafine pulverization treatment time is 2min, and the gallnut homogenate (260mL) is obtained Except, the rest are the same as step 1 of embodiment 1.

[0082] 2. Ultrasonic treatment

[0083] Except that the ultrasonic treatment time is 30 min, and the ultrasonic pulse time (on / off) is 3 s / 10 s (usually 3-5 s / 8-10 s), the rest is the same as step 2 of embodiment 1.

[0084] 3. Binding reaction

[0085] Except that the stirring speed during the combined reaction is 250rpm; it is carried out in 2 stages, and the first and second stage reaction temperatures are 25 and 40°C respectively; the first and second stage reaction time is 6h, the rest are the same as the steps of Example 1 3 same.

[0086] 4. Filtration a...

Embodiment 1B

[0089] Embodiment 1B (continuous wall breaking, CB)

[0090] 1. Superfine pulverization treatment

[0091] In addition to adding 20g gallnut sieve sieve into 160mL water, the ratio of the quality of gallnut sieve sieve to the volume of water is 1:8 (m / v), and the ultrafine pulverization treatment time is 5min, and the gallnut homogenate (180mL) is obtained Except, the rest are the same as step 1 of embodiment 1.

[0092] 2. Ultrasonic treatment

[0093] Except that the ultrasonic treatment time is 20 min, and the ultrasonic pulse time (on / off) is 5 s / 8 s (usually 3-5 s / 8-10 s), the rest is the same as step 2 of embodiment 1.

[0094] 3. Binding reaction

[0095] Except that the stirring speed is 100rpm during the combined reaction; it is divided into 5 stages, and the reaction temperatures of the first, second, third, fourth, and fifth stages are respectively 20, 25, 30, 35, and 40°C; the first, second, and third stages , 4, and 5 stages of reaction time are respectively 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com