Processing method for improving anti-radiation performance of quartz optical fibers

The technology of a quartz optical fiber and a processing method, which is applied in the field of optical communication, can solve problems such as difficulty in adjusting and reducing the structural stability of the quartz optical fiber material, and achieve the effects of low cost, stable microstructure of the quartz optical fiber material, and simple and easy manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: Now the preferred embodiment involved in the present invention is described as follows in conjunction with the flow chart:

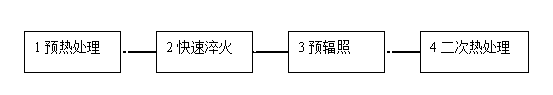

[0018] see figure 1 , the present invention adopts high-purity silica fiber material, and its processing process is as follows: (1) High-purity silica fiber material is preheated at a temperature of 1200~1400 °C, and the holding time is 1~2hr; (2) Preheated silica fiber material Rapid quenching in water; (3) Pre-irradiation treatment of the quenched quartz fiber material, the radiation dose is greater than 10kGy; (4) Reheat treatment of the pre-irradiation treatment of the quartz fiber material, the heat treatment temperature is 800~1000°C.

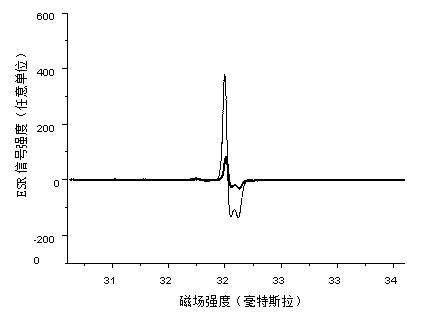

[0019] figure 2 It shows the electron spin resonance (ESR: Electron Spin Resonance) signal obtained by experimental measurement of the high-purity silica fiber material treated by this method, and then irradiated with a dose greater than 10kGy, where the thin black line and the thick black line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com