Lubricating grease for space aircraft and preparation method thereof

A space vehicle and lubricating grease technology, applied in the field of lubricating grease, can solve problems such as poor fluidity, mutual influence, complex sensitivity, and lack of lubrication, achieve good high-temperature adhesion and low-temperature flow, and solve unstable product performance , Reduce the effect of friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

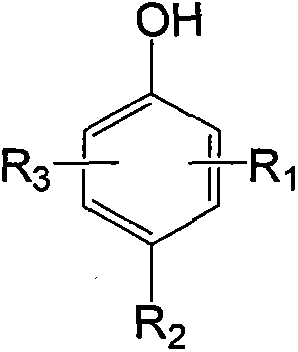

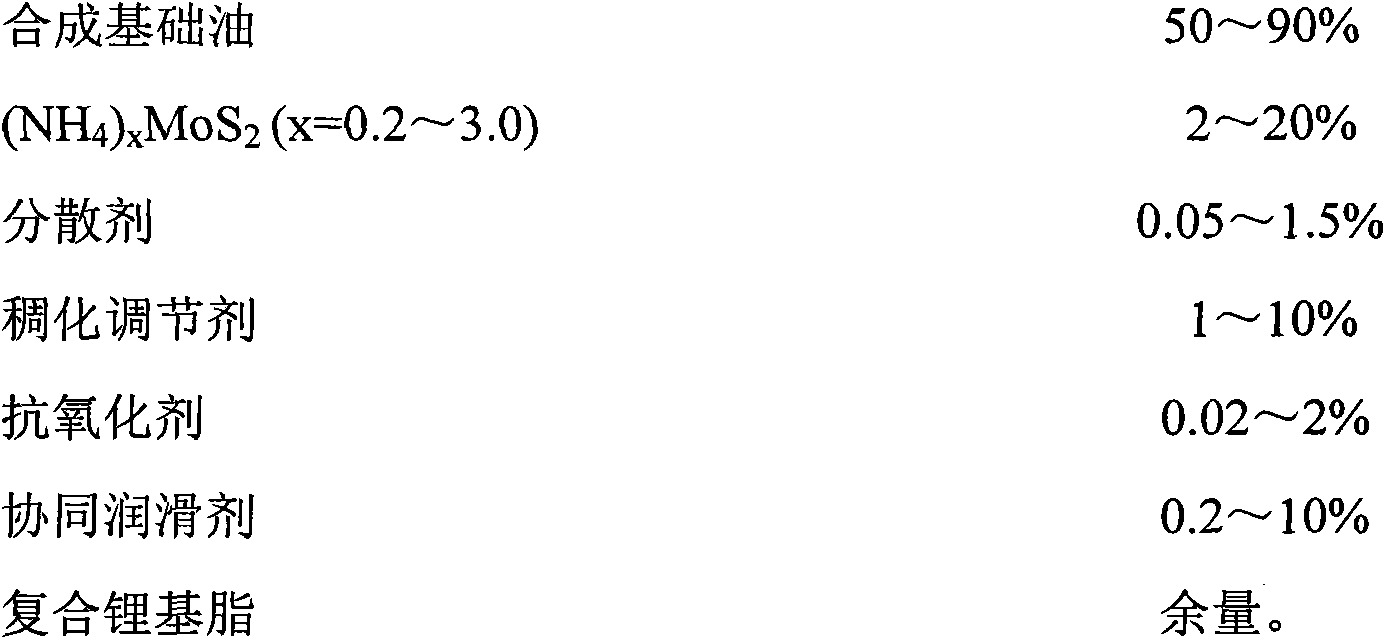

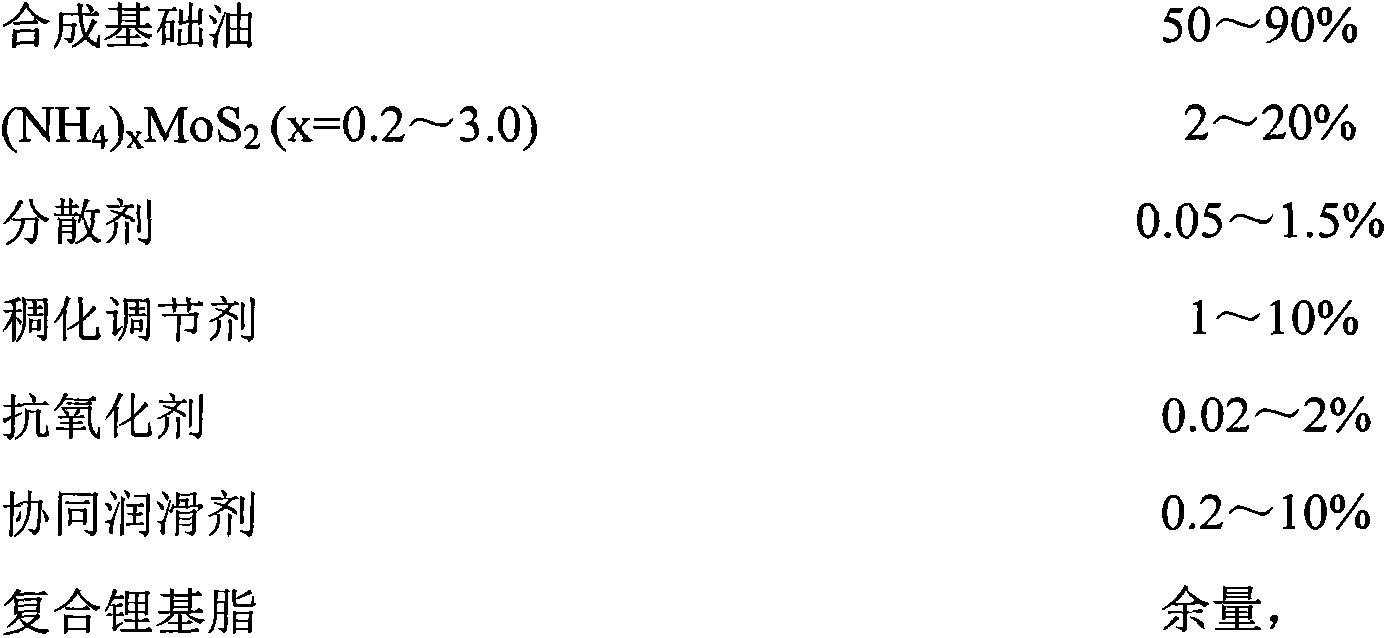

Method used

Image

Examples

Embodiment Construction

[0026] 1. Mix 3.0g NH 4 MoS 2 , 0.05g glycerol and 1.5g polytetrafluoroethylene were added to 30g In 180R polyalphaolefin base oil, ultrasonically disperse for 10 minutes, add 0.02g of 2,5-di-tert-butylhydroquinone, 6.0g of molybdenum disulfide nanospheres, 4.0g of micron tungsten disulfide in turn, stir and disperse evenly, then add 6.2 g12-methylstearic acid and an aqueous solution containing 6.0g of lithium hydroxide, heat to 90°C and keep it warm until no bubbles are released, then keep saponification for 0.5h, add 18.23g of pimelic acid and keep it for 2h, heat to 120°C for 30min to dehydrate , heated up to 200°C for 0.5h, added 20g 180R polyalphaolefin base oil, stir and blend, stop heating, grind and homogenize in a three-roll machine, suitable for lubrication of Al alloy friction pairs of space vehicles.

[0027] 2. Add 10.0gNH 4 MoS 2 , 1.0g glycerol and 5.5g polytetrafluoroethylene were added to 40g In the 180R polyalphaolefin base oil, ultrasonically dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com