Hair-saving and hair removing tanning method by adopting micro enzyme-alkaline process

A technology for hair preservation and depilation and enzyme alkali, which is applied in the field of tanning by the micro-enzyme alkali method for hair preservation and depilation. effect of substance content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

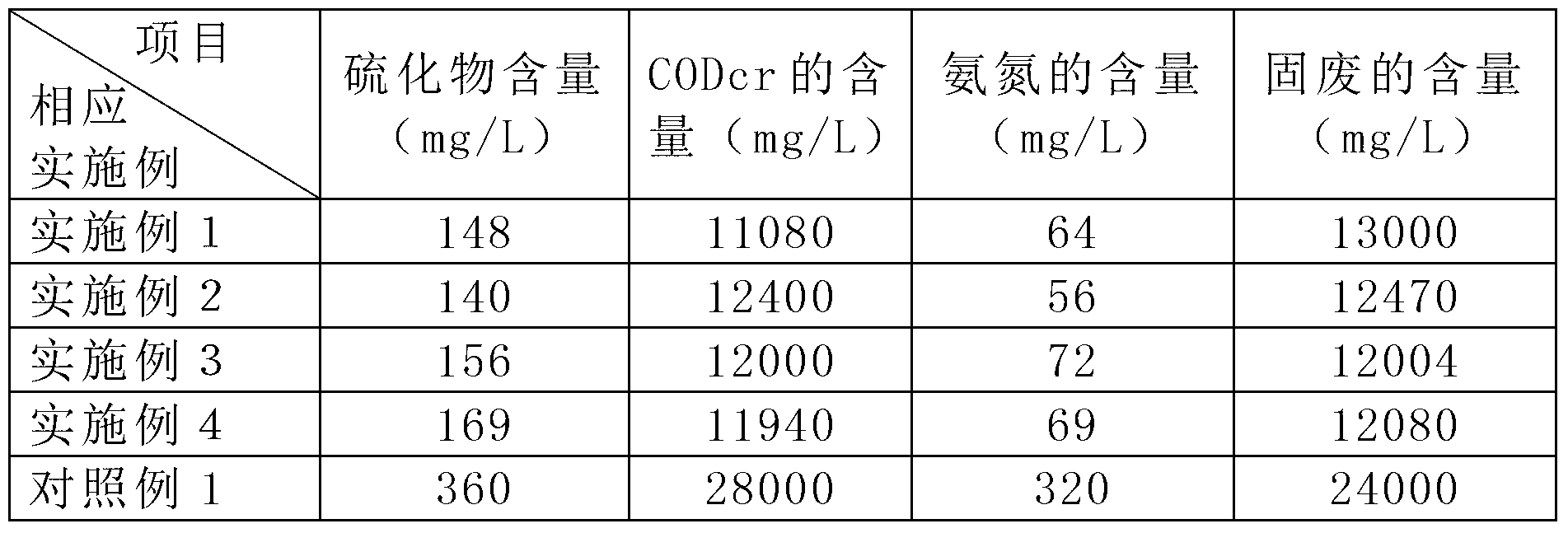

Examples

Embodiment 1

[0023] Put the cowhide that has been conventionally soaked and de-fleshed into the drum, and add water with a tare weight of 300wt%, adjust the water temperature to 24°C, and then add 0.8wt% of tare-containing enzyme additives and 0.1wt% of soda ash. The above-mentioned enzyme-containing auxiliary agent is an enzyme-containing non-organic amine substance. Adjust the pH value of the bath to about 9.5, turn it on and off, and continue for 60 minutes. Then add lime with a tare weight of 1.0 wt% to the bath to maintain the bath. Liquid temperature is 24 ℃, after rotating again 60min, then, add depilatory agent in bath liquid again, described depilatory agent is the mixture of sodium sulfide and sodium hydrosulfide, and the consumption of sodium sulfide is 1.2wt% of tare weight, The consumption of sodium hydrosulfide is 0.8wt% of tare weight, continue to maintain the temperature of the bath liquid at 24°C, combine rotation and stop, stop for 30 minutes every 30 minutes, and maintain...

Embodiment 2

[0025] Put the cowhide that has been conventionally soaked and de-fleshed into the drum, and add water with a tare weight of 250wt%, adjust the water temperature to 20°C, and then add 1.2wt% of tare-containing enzyme additives and 0.2wt% of soda ash. The above-mentioned enzyme-containing auxiliary agent is an enzyme-containing non-organic amine substance, adjust the pH value of the bath to be about 10, turn on and off, and continue for 90 minutes, then add lime with a tare weight of 2.0wt% in the bath to maintain the bath. Liquid temperature is 20 ℃, after rotating again 80min, then, add depilatory agent in bath liquid again, described depilatory agent is the mixture of sodium sulfide and sodium hydrosulfide, and the consumption of sodium sulfide is 1.1wt% of tare weight, The consumption of sodium hydrosulfide is 0.8wt% of tare weight, continue to maintain the temperature of the bath liquid at 20°C, combine rotation and stop, stop for 30 minutes every 30 minutes, and maintain 1...

Embodiment 3

[0027]Put the cowhide that has been conventionally soaked and de-fleshed into the drum, add water with a tare weight of 280wt%, adjust the water temperature to 25°C, and then add 0.7wt% of tare-containing enzyme additives and 0.2wt% of soda ash. The above-mentioned enzyme-containing auxiliary agent is an enzyme-containing non-organic amine substance, and the enzyme-containing non-organic amine substance is Smur blue 4008-C, and the pH value of the bath is adjusted to be about 9.0. , then add lime with a tare weight of 1.5wt% in the bath, maintain the temperature of the bath at 25°C, and rotate for 50 minutes, then add a depilatory to the bath, the depilatory being sodium sulfide and hydrosulfurized A mixture of sodium, and the amount of sodium sulfide is 1.0wt% of the tare weight, the amount of sodium hydrosulfide is 0.8wt% of the tare weight, continue to maintain the temperature of the bath liquid at 25 ° C, combine rotation and stop, every turn 30min stop 30min, maintain 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com