Method for constructing wettability gradient surface by anodization

An anodic oxidation and gradient surface technology, applied in the field of interface chemistry, can solve the problems of difficult operation, non-repeatability, difficulty in large-scale, high-precision production, etc., and achieve the effects of wide application, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example provides a method for anodizing to construct a one-dimensional wettability gradient surface, wherein the target sample is a carbon fiber plate, and the specific anodizing process includes the following steps:

[0036] The first step, the preparation of electrolyte:

[0037] A sodium hydroxide solution with a concentration of 0.05 mol / L was prepared as the electrolyte.

[0038] The second step, target sample surface treatment:

[0039] Polish the surface of the carbon fiber plate to remove organic matter on the surface, then rinse it with deionized water, and dry it for use.

[0040] The third step is to prepare the gradient surface:

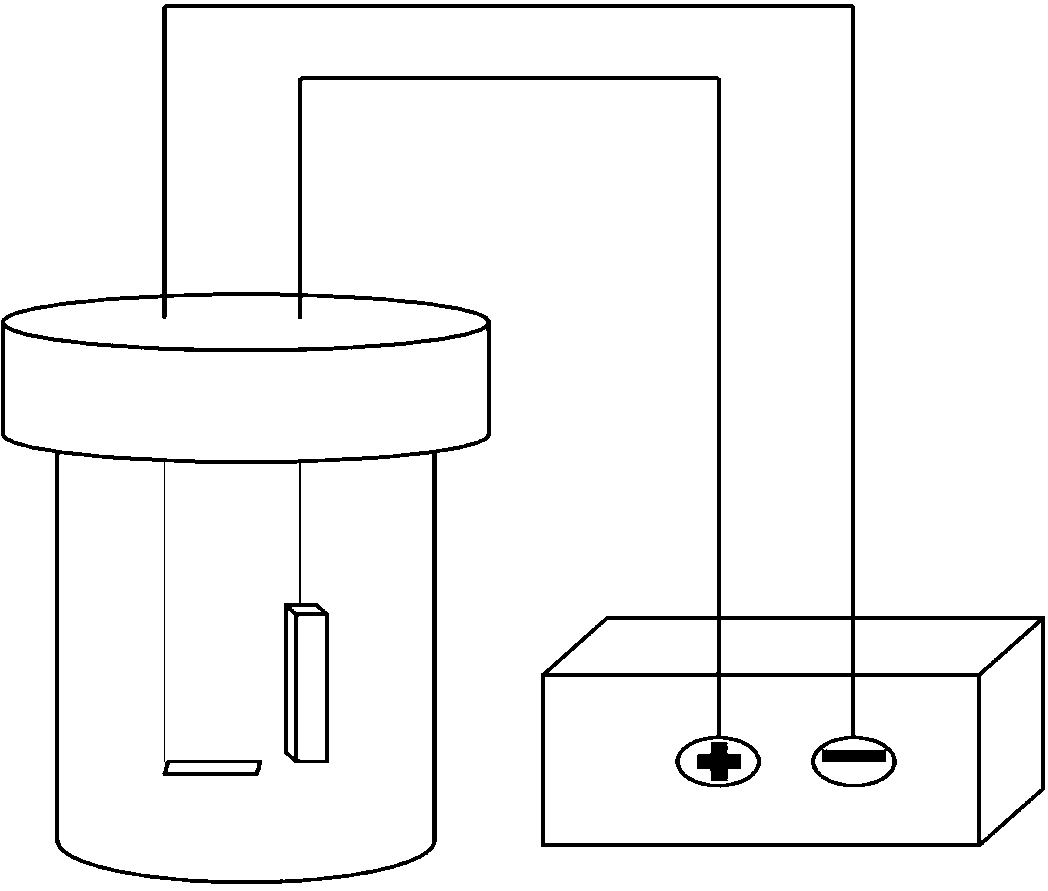

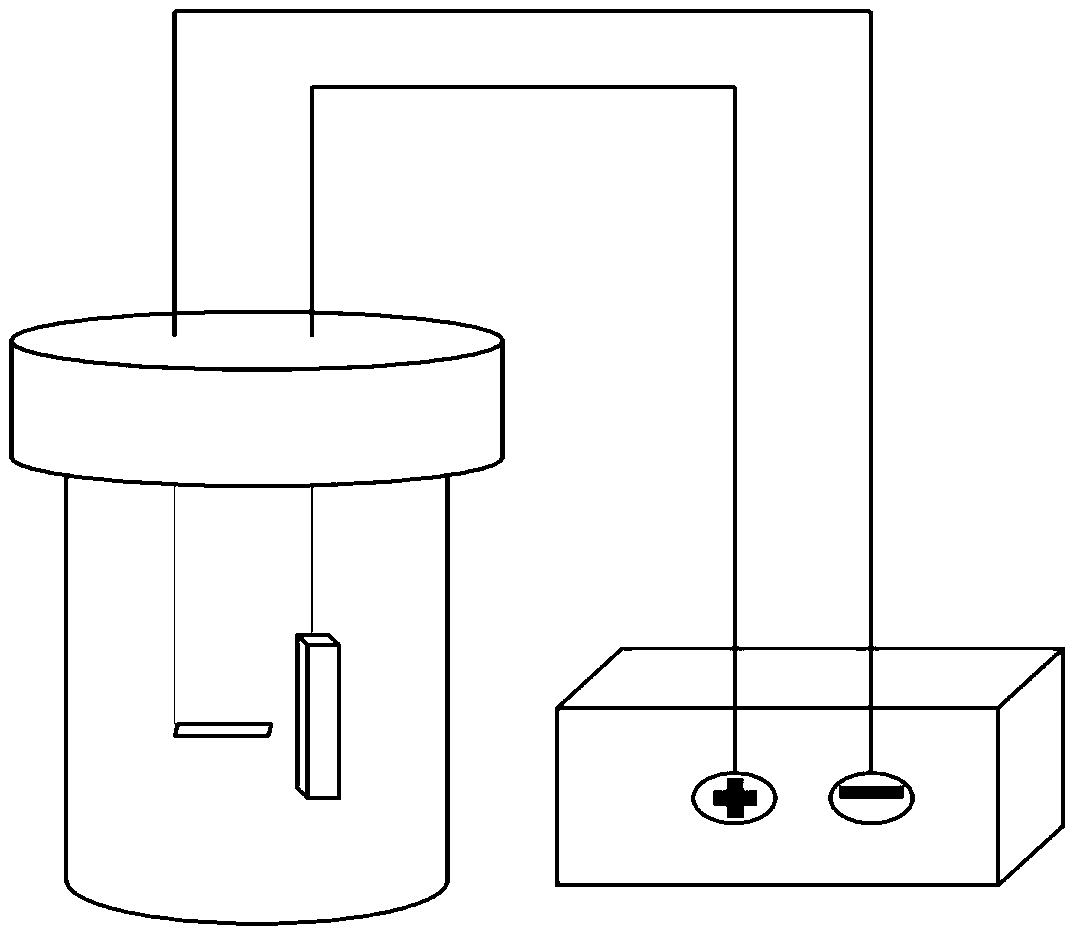

[0041] Use a DC stabilized voltage and current power supply to anodize the target sample. The anode is the target sample, and the cathode is an inert platinum electrode. Adjust the relative position of the anode and the cathode so that the distance between the cathode and the bottom of the anode is 2mm. The specific device i...

Embodiment 2

[0043] This example provides a method for anodizing to construct a one-dimensional wettability gradient surface, wherein the target sample is a carbon fiber plate, and the specific anodizing process includes the following steps:

[0044] The first step, the preparation of electrolyte:

[0045] A sodium hydroxide solution with a concentration of 0.2 mol / L was prepared as the electrolyte.

[0046] The second step, target sample surface treatment:

[0047] Polish the surface of the carbon fiber plate to remove organic matter on the surface, then rinse it with deionized water, and dry it for use.

[0048] The third step is to prepare the gradient surface:

[0049] Use a DC stabilized voltage and current power supply to anodize the target sample. The anode is the target sample, and the cathode is an inert platinum electrode. Adjust the relative position of the anode and the cathode so that the distance between the cathode and the bottom of the anode is 5mm. The specific device is...

Embodiment 3

[0051]This example provides a method for anodizing to construct a one-dimensional wettability gradient surface, wherein the target sample is a carbon fiber plate, and the specific anodizing process includes the following steps:

[0052] The first step, the preparation of electrolyte:

[0053] Prepare a sodium hydroxide solution with a concentration of 0.05 mol / L.

[0054] The second step, target sample surface treatment:

[0055] Polish the surface of the carbon fiber plate to remove organic matter on the surface, then rinse it with deionized water, and dry it for use.

[0056] The third step is to prepare the gradient surface:

[0057] Use a DC stabilized voltage and current power supply to anodize the target sample. The anode is the target sample, and the cathode is an inert platinum electrode. Adjust the relative position of the anode and the cathode so that the distance between the cathode and the bottom of the anode is 8mm. The specific device is as follows: Figure 1A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com