Wafer defect cross-section observation device

An observation device and wafer technology, applied in semiconductor/solid-state device testing/measurement, etc., can solve the problems of cutting, difficult to control precision, low precision, etc., and achieve the effect of convenient operation, simple process and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

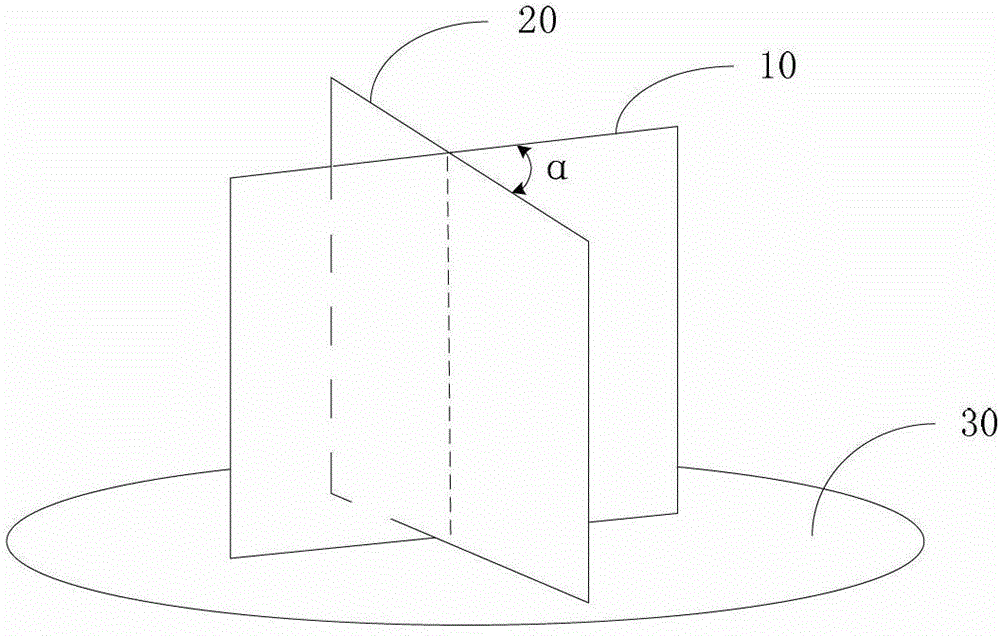

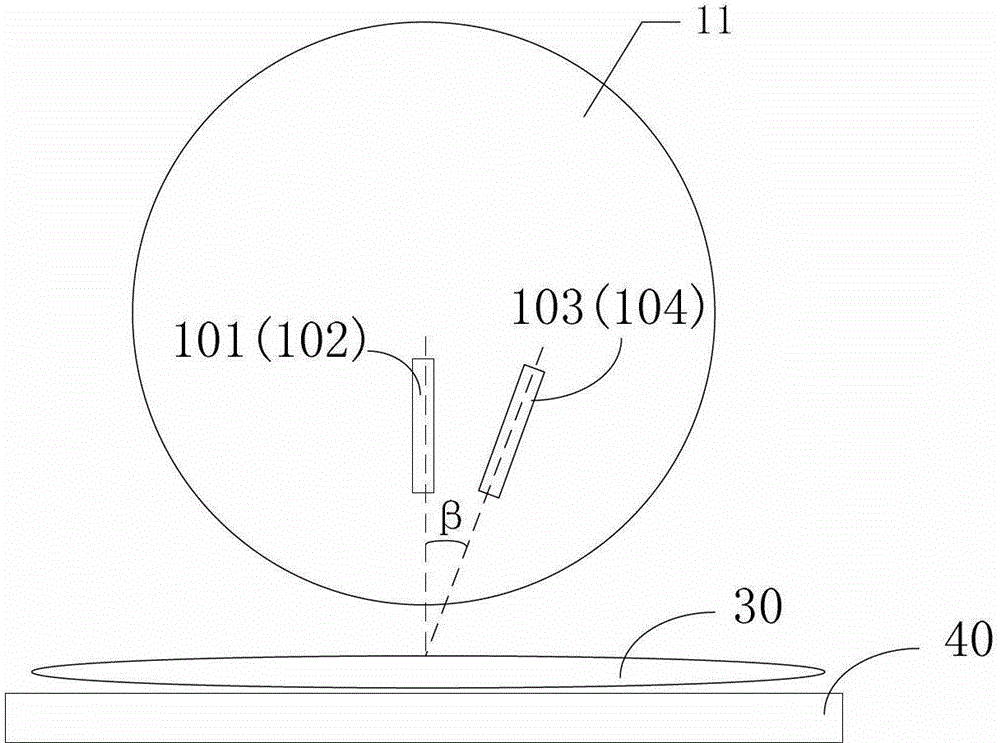

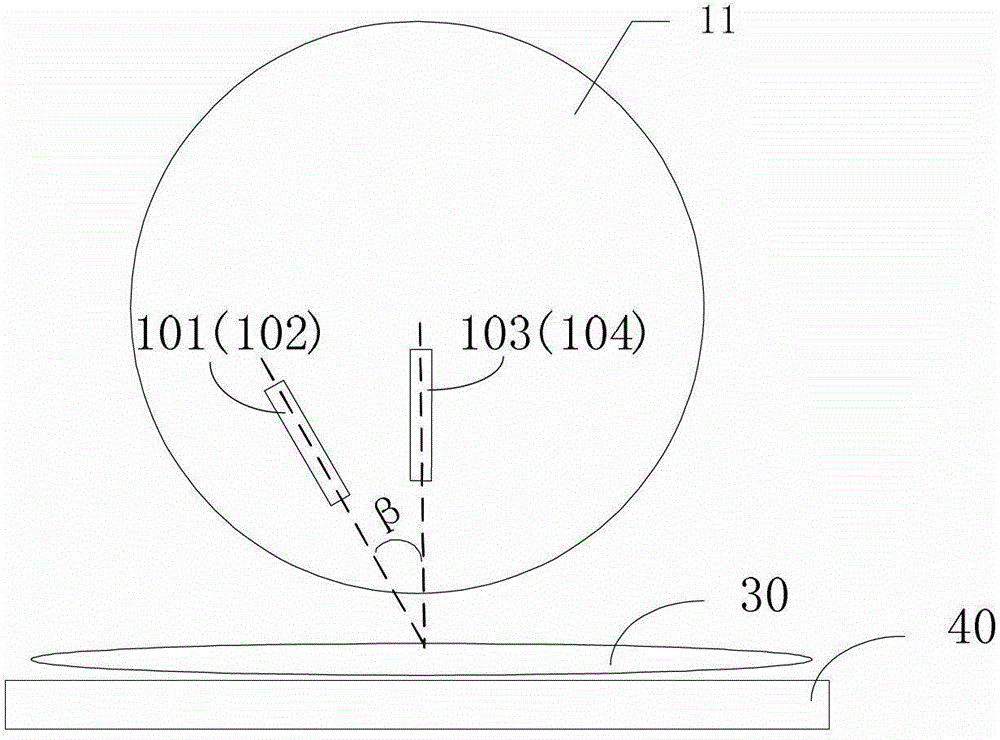

[0017] Such as figure 1 , Figure 2A-2B with image 3 As shown, the wafer defect cross-cut observation device provided by the embodiment of the present invention is applied to cross-cut a wafer at a defect and observe the defect morphology of the cut surface in the field of semiconductor processing.

[0018] The bottom of the wafer defect cross-cutting observation device can be provided with a mounting table 40 for placing the wafer to be inspected. The device specifically includes: a focused ion gun 101, which is arranged in a first plane 10 perpendicular to the wafer surface 30, and is used to inject a high-energy ion beam on the wafer surface 30 to cut the wafer to form a wafer section; and a scanning electron gun 103, which is arranged The position in the first plane is different from that of the focused ion gun 101, and is used to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com