Preparation method of sea urchin-shaped cadmium sulfide nanospheres

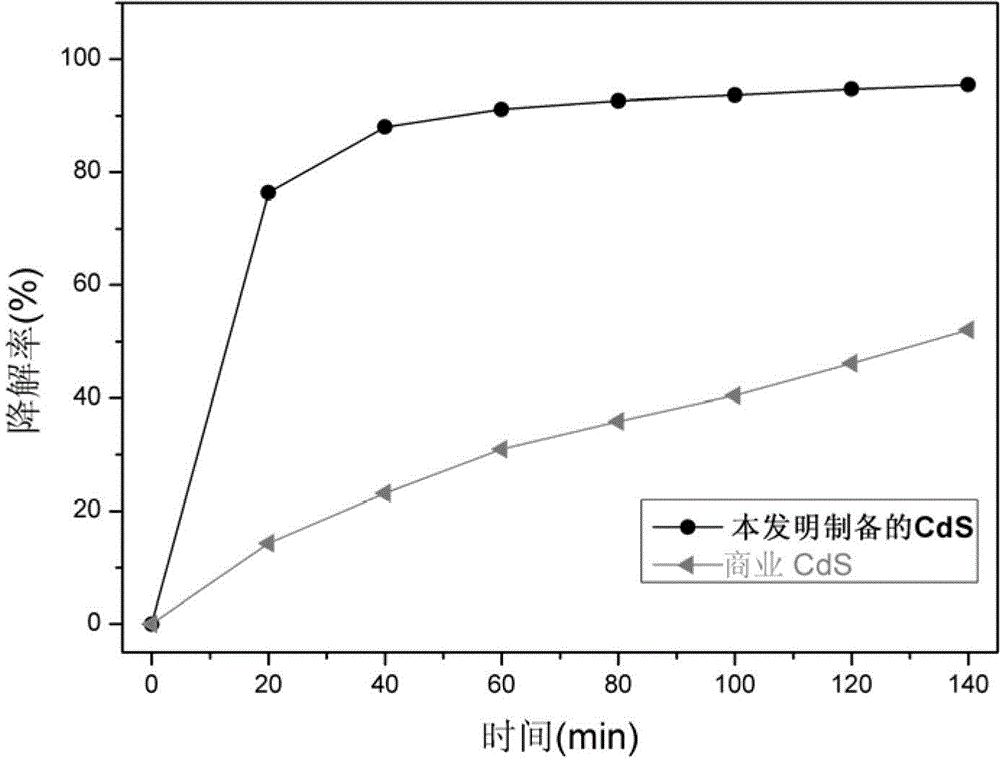

A cadmium sulfide and nanosphere technology, applied in the direction of cadmium sulfide, nanotechnology, nanotechnology, etc., can solve the problems of complex cadmium sulfide process, difficult mass production, long preparation cycle, etc., and achieve short preparation cycle and high repeatability , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.05g (0.12mmol) of cadmium diethyldithiocarbamate into a flask, measure 48ml of ethylene glycol and 2ml of distilled water into the flask to make a mixed solution, and put the above flask into atmospheric pressure microwave-assisted synthesis / In the extraction reaction apparatus (the flask is equipped with a condenser and tap water), after heating at 90°C and 500W for 5 minutes under magnetic stirring (500 rpm), then heating at 160°C and 500W for 5 minutes, the reaction solution was centrifuged ( 8000rpm, 10min), the precipitate was washed with distilled water and absolute ethanol for 2-3 times in sequence, and then dried at 50°C for 1h to obtain 15mg of sea urchin-shaped cadmium sulfide nanospheres with a yield of 86.5%.

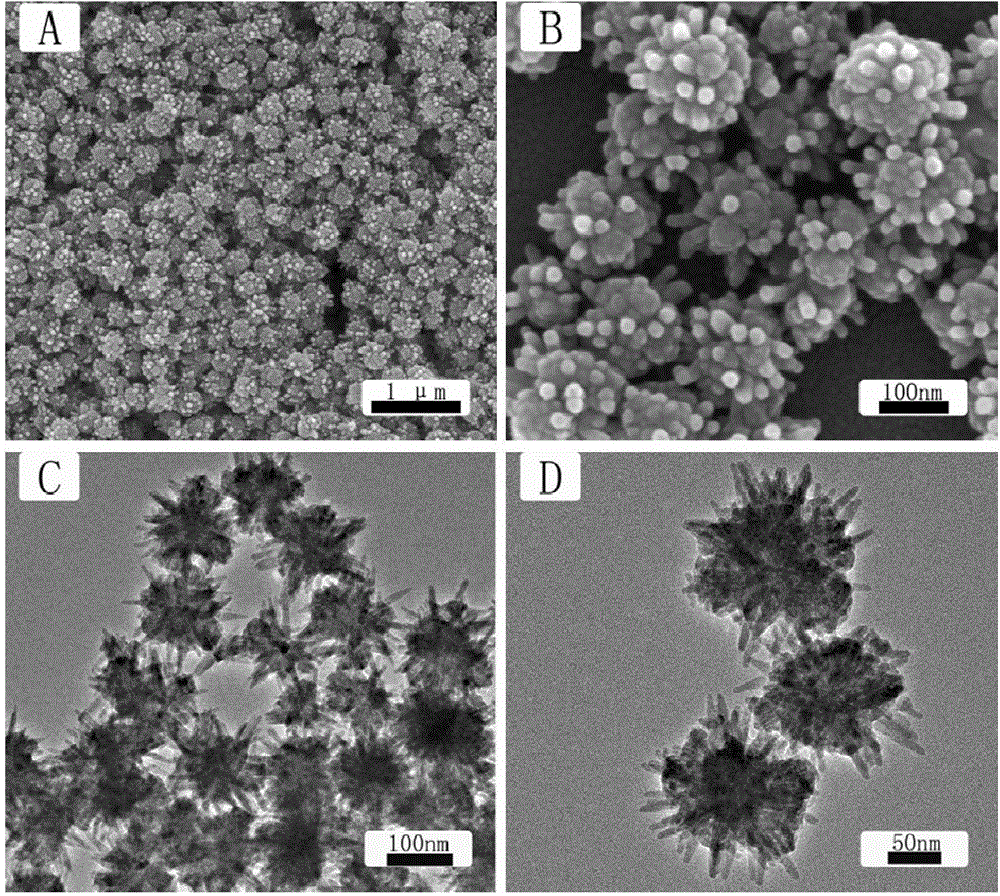

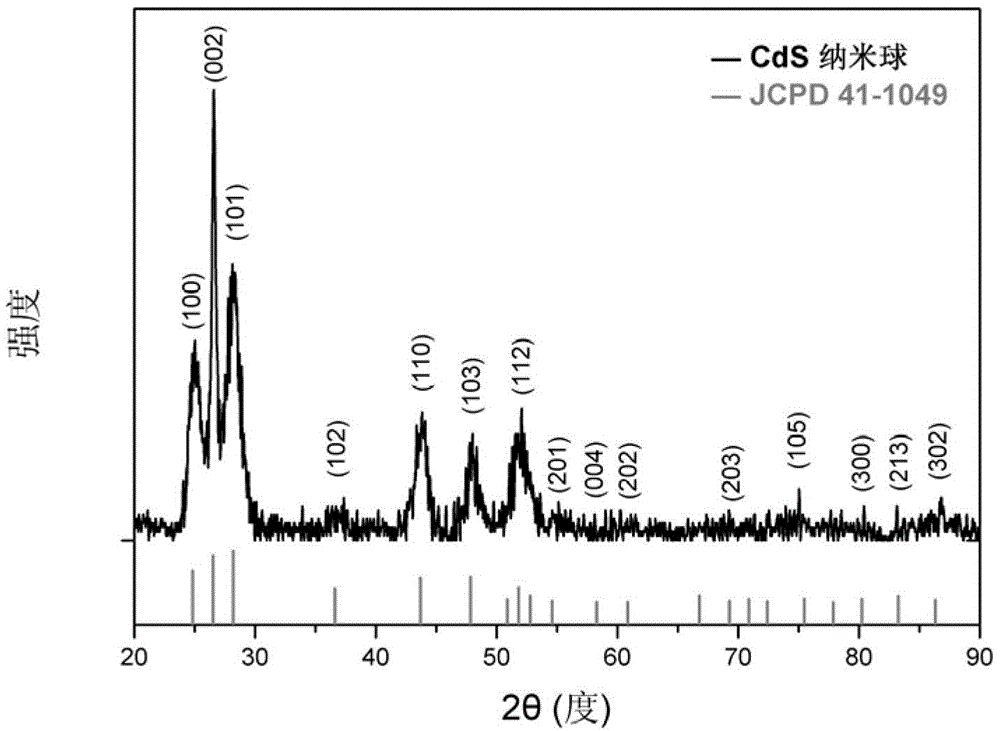

[0023] Scanning electron microscope (SEM) image of sea urchin-shaped cadmium sulfide nanospheres is shown in figure 1 As shown in A and B, it can be seen from A and B that the product has good monodispersity, uniform appearance, clean surfac...

Embodiment 2

[0025] Change the amount of ethylene glycol and pure water in Example 1 to: get 48ml ethylene glycol and 2ml distilled water and pour them into the flask respectively, then the magnetic stirring speed is 1000 rpm, and other operations are the same as in Example 1 to obtain sea urchin-shaped The cadmium sulfide nanosphere is 14 mg, the diameter of the ball is 130-160 nm, and there are a large number of flat-headed cylindrical spines distributed on the surface of the ball. The length of the spines is 20-40 nm, and the width is 10-20 nm.

Embodiment 3

[0027] The amount of cadmium diethyldithiocarbamate in Example 1 was changed to 0.1 g (0.24 mmol), and other operations were the same as in Embodiment 1. 30 mg of sea urchin-shaped cadmium sulfide nanospheres were obtained, with a diameter of 140-180 nm. There were a large number of flat-headed cylindrical spines distributed on the surface of the balls. The spines were 30-50 nm long and 15-25 nm wide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com