Method for preparing copper indium selenium sulfur powder or thin film used in thin-film solar cell

A technology for solar cells and copper indium sulfide selenium, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of complex heat treatment process and harsh preparation conditions, and achieves improved utilization of sunlight, low cost of raw materials, and short process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

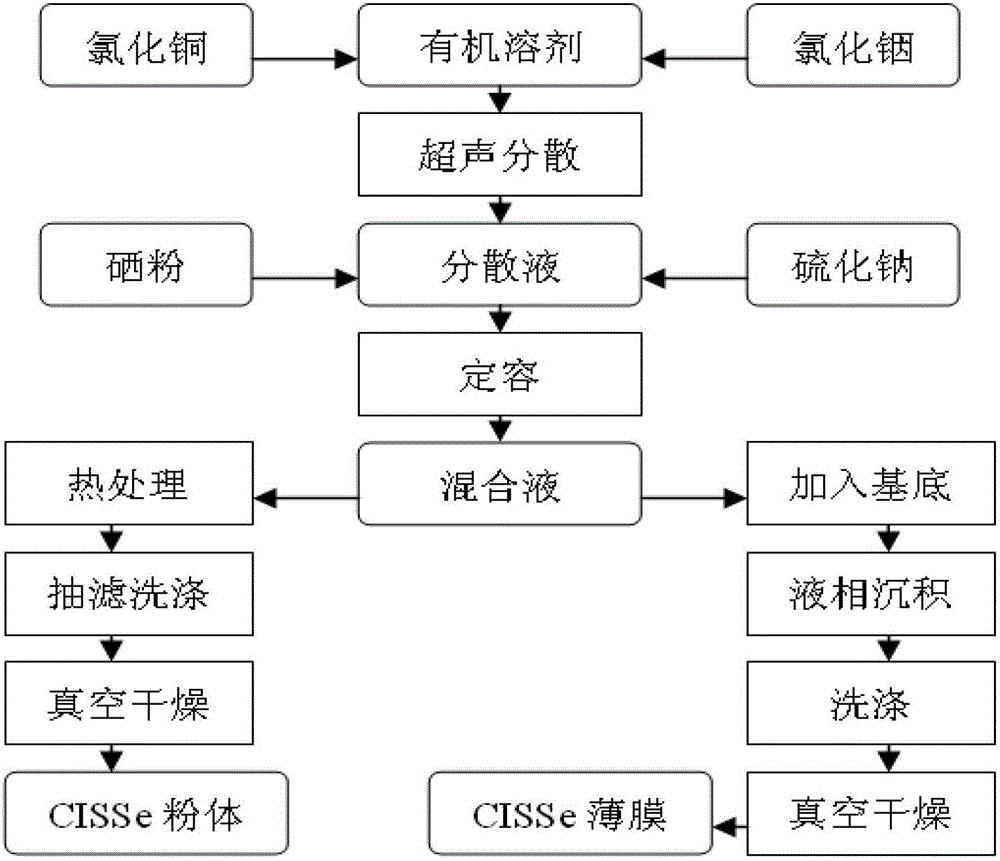

Method used

Image

Examples

Embodiment 1

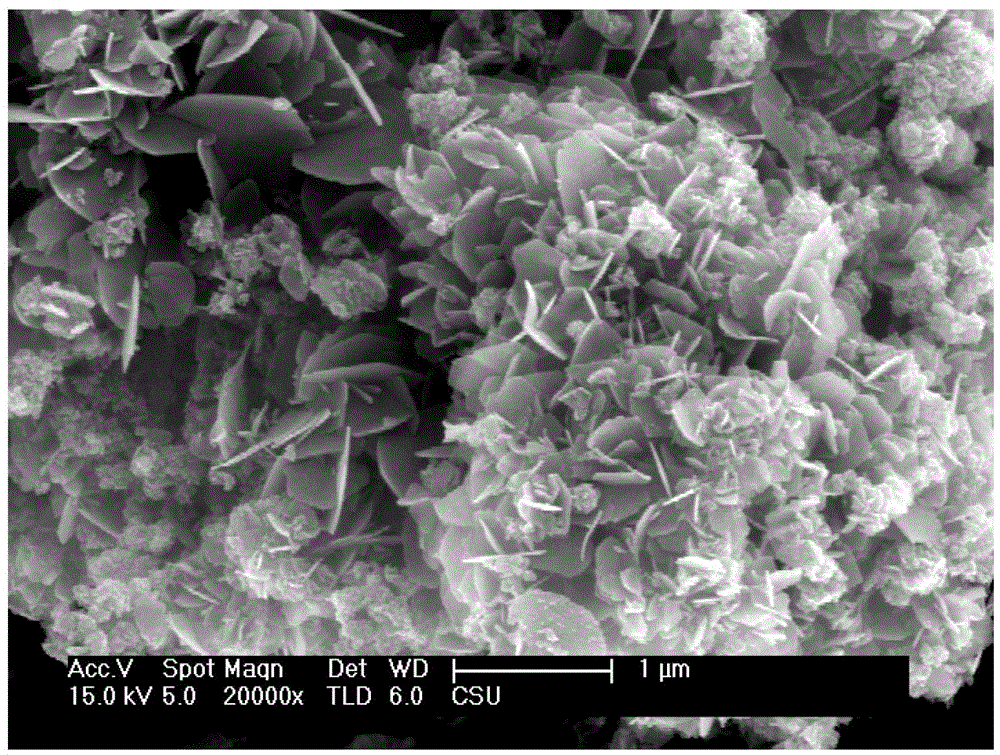

[0038] Weighing: Weigh 0.8805g InCl on an electronic analytical balance (reading accuracy 0.1mg) 3 4H 2 O, 0.5115g CuCl 2 2H 2 O, and transferred it to a beaker containing 30 mL of ethanolamine and covered it with plastic wrap.

[0039] Dispersion: put the beaker into an ultrasonic disperser, and disperse for about 30 minutes under an ultrasonic power of 300W to obtain a dispersion.

[0040]Constant volume: weigh 0.2880g Na on the electronic analytical balance 2 S·9H 2 O. Add 0.3792g of Se powder into the dispersion liquid, stir evenly to obtain a mixed liquid; transfer the dispersed mixed liquid into a 100mL reactor and use ethanolamine to set the volume to about 80% of the reactor volume.

[0041] Heat treatment: cover the reaction kettle, tighten it and seal it, put it in a constant temperature box and react at 180°C for 15h.

[0042] Suction filtration and washing: After cooling to room temperature with the furnace, the reaction product was vacuum filtered and washed...

Embodiment 2

[0045] Weighing: Weigh 0.8805g InCl on an electronic analytical balance 3 4H 2 O, 0.5115g CuCl 2 2H 2 O, transfer it to a beaker with about 30 mL of ethanolamine and cover it with plastic wrap.

[0046] Dispersion: put the beaker into an ultrasonic disperser, and disperse for about 30 minutes under an ultrasonic power of 300W to obtain a dispersion.

[0047] Constant volume: weigh 0.7200g Na on the electronic analytical balance 2 S·9H 2 O. Add 0.2370g of Se powder into the dispersion liquid, stir evenly to obtain a mixed liquid; transfer the dispersed mixed liquid into a 100mL reactor and use ethanolamine to set the volume to about 80% of the reactor volume.

[0048] Heat treatment: cover the reaction kettle, tighten it and seal it, put it in a constant temperature box and react at 180°C for 15 hours.

[0049] Suction filtration and washing: After cooling to room temperature with the furnace, the product was successively vacuum-suctioned and washed several times with dei...

Embodiment 3

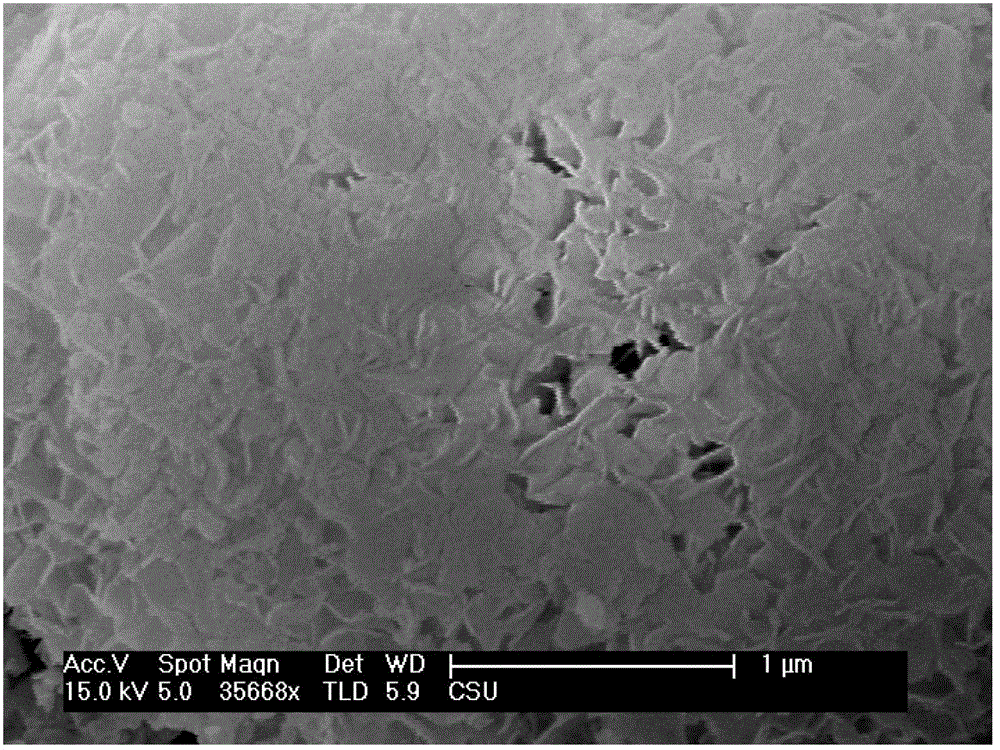

[0052] Weighing: Weigh 0.8805g InCl on an electronic analytical balance 3 4H 2 O, 0.5115g CuCl 2 2H 2 O, and transfer it to a beaker containing 30 mL of ethylenediamine, and cover it with plastic wrap.

[0053] Dispersion: Put the beaker into an ultrasonic disperser, and disperse for about 30 minutes under an ultrasonic power of 300W to obtain a dispersion.

[0054] Constant volume: weigh 1.1520g Na on the electronic analytical balance 2 S·9H 2 O. Add 0.0948g of Se powder into the dispersion liquid, stir evenly to obtain a mixed liquid; transfer the dispersed mixed liquid into a 100mL reaction kettle, add an ITO transparent conductive glass substrate with a specification of 25mm×75mm at the same time, and use ethanolamine to fix the volume to the reaction kettle About 80% of the volume.

[0055] High-temperature deposition: cover the reaction kettle, tighten it and seal it, put it in a constant temperature box and deposit at a constant temperature of 180°C for 15 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com