Method for separating high-purity cinnamyl aldehyde and cinnamyl acetate from cinnamon oil

A technology of cinnamyl acetate and cinnamon oil, which is applied in the separation/purification of carbonyl compounds, preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problems of increasing environmental protection pressure, loss, and low purity, and achieve improved yield, Prevents oxidation at high temperature and increases separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

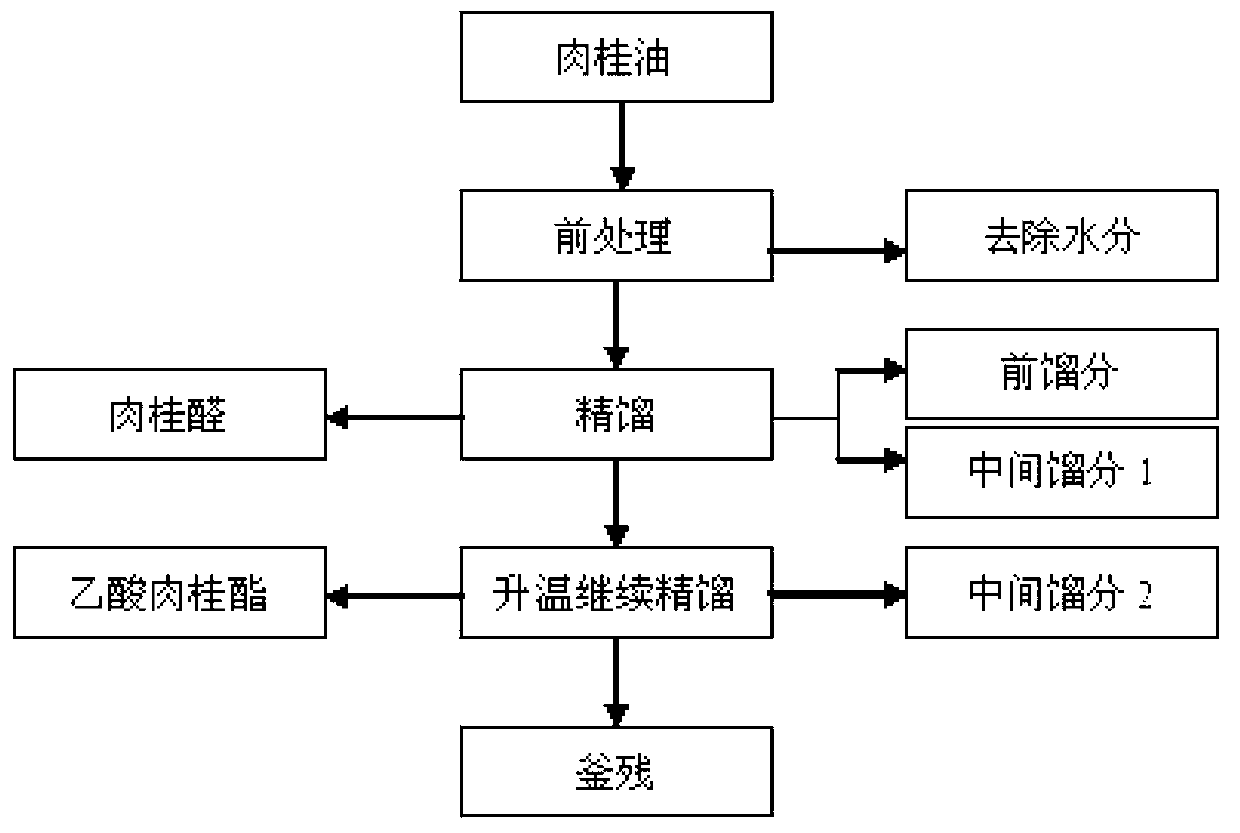

[0014] The method for separating high-purity cinnamaldehyde, cinnamyl acetate from cinnamon oil of the present invention comprises the steps:

[0015] 1000.0 g of cinnamon oil with a cinnamaldehyde content of 83% and a acetic acid cinnamaldehyde content of 1.5% is divided into glass containers, and 250 g of NaCl is added for pretreatment. The temperature of the kettle is 145°C, the vacuum degree is 2mmHg, the total reflux is 30min, and then rectification is carried out with a reflux ratio of 10:1. When the purity of cinnamaldehyde reaches 99%, the reflux ratio is changed to 1:4, and the cinnamaldehyde product is received. After receiving the cinnamaldehyde product, the temperature of the kettle was raised to 150°C, the vacuum degree remained unchanged, and the total reflux was carried out for 30 minutes, and then rectification was carried out at a reflux ratio of 10:1. When the purity of cinnamyl acetate reached 95%, the reflux ratio became 1:4, receive cinnamyl acetate produc...

Embodiment 2

[0017] Another example of the method for separating high-purity cinnamaldehyde, cinnamyl acetate from cinnamon oil of the present invention, comprises the steps:

[0018] Pack 1000.0 g of cinnamon oil with cinnamaldehyde content of 83% and acetic acid cinnamaldehyde content of 1.5% into a glass container, add 125g of NaCl for pretreatment, put the treated cinnamon oil into the rectification tower kettle, and rectify tower kettle The temperature is 150°C, the vacuum degree is 8mmHg, the total reflux is 20min, and then rectification is carried out with a reflux ratio of 8:1. When the purity of cinnamaldehyde reaches 99%, the reflux ratio is changed to 1:4, and the cinnamaldehyde product is received. After receiving the cinnamaldehyde product, the temperature of the kettle was raised to 155°C, the vacuum degree remained unchanged, and the total reflux was carried out for 20 minutes, and then rectification was carried out at a reflux ratio of 8:1. When the purity of cinnamyl acetat...

Embodiment 3

[0020] Yet another example of the method for separating high-purity cinnamaldehyde, cinnamyl acetate from cinnamon oil of the present invention, comprises the steps:

[0021] Pack 1000.0 g of cinnamon oil with cinnamaldehyde content of 83% and acetic acid cinnamaldehyde content of 1.5% into a glass container, add 200g of NaCl for pretreatment, put the treated cinnamon oil into the rectification tower kettle, and rectify tower kettle The temperature is 148°C, the vacuum degree is 5mmHg, the total reflux is 40min, and then rectification is carried out with a reflux ratio of 7:1. When the purity of cinnamaldehyde reaches 99%, the reflux ratio is changed to 1:4, and the cinnamaldehyde product is received. After receiving the cinnamaldehyde product, the temperature of the kettle was raised to 153°C, the vacuum degree remained unchanged, and the total reflux was carried out for 40 minutes, and then rectification was carried out at a reflux ratio of 7:1. When the purity of cinnamyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com