Continuous preparation method of trinitromalonaldehydic acid dipotassium salt

A technology of dipotassium trinitropropionylate and potassium nitrite, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., and can solve the problem of not seeing the synthesis of dipotassium trinitropropionate By-product recycling, a large amount of waste liquid, potential safety hazards and other issues, to achieve the effect of stabilizing product quality, solving pollution, and realizing recycling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

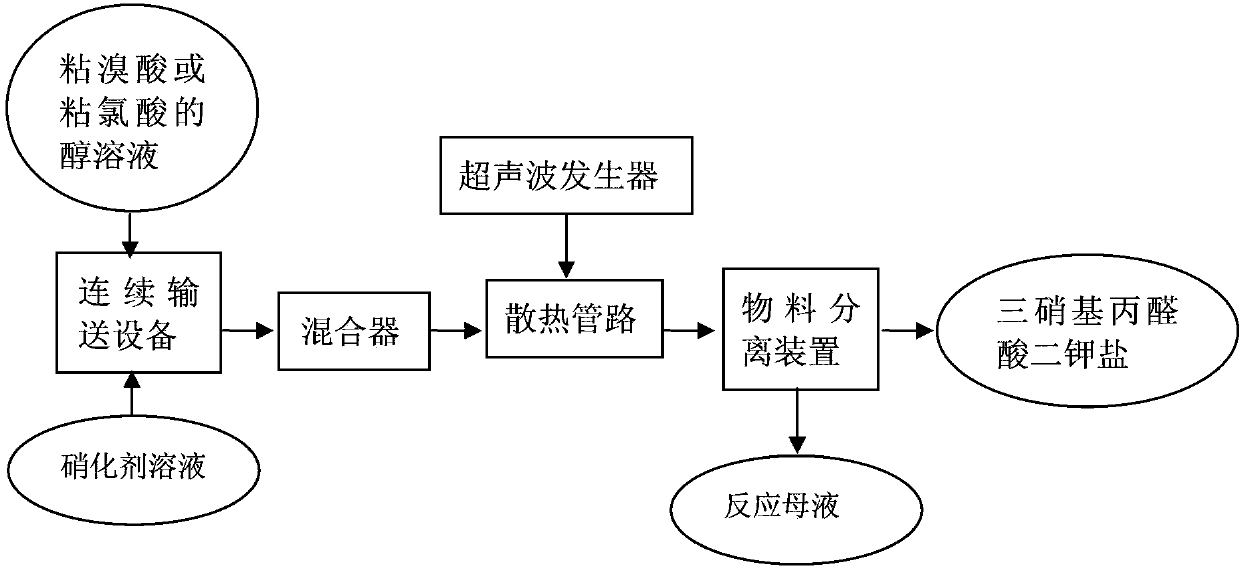

Method used

Image

Examples

Embodiment 1

[0031] A peristaltic pump is used as the continuous conveying equipment for liquid materials. The mixer is a static mixer. The liquid material conveying pipeline is a translucent polytetrafluoroethylene tube with an inner diameter of 3mm. The solid-liquid separation of the material adopts a vacuum filtration device, and the liquid raw materials are mixed. The pipeline is immersed in a cold water bath for heat dissipation, and an ultrasonic generator is arranged on the heat dissipation pipeline.

[0032] Adopting mass percentage composition is that 95.0% potassium nitrite and mass percentage composition are 98.0% mucinous bromic acid as raw material, first take by weighing 63 grams of mucinous bromic acid and dissolve in 320ml95% alcohol for subsequent use; In addition, take 105 grams of sub Potassium nitrate is dissolved in 380ml volume concentration and is standby in the ethanol aqueous solution of 40%.

[0033] Two peristaltic pumps are used to control the flow of the raw ma...

Embodiment 2

[0039] A miniature plunger pump is used as the continuous conveying equipment for liquid materials. The mixer is a static mixer. The liquid material conveying pipeline is a translucent polytetrafluoroethylene tube with an inner diameter of 3 mm. The solid-liquid separation of the material adopts a vacuum filtration device, and the liquid raw material is mixed. The final pipeline is immersed in a cold water bath for heat dissipation, and two ultrasonic generators are arranged on the heat dissipation pipeline.

[0040] The same raw material and continuous reaction process as in Example 1 are used to prepare dipotassium trinitropropionic acid, which only improves the material delivery flow rate of 1 times, that is, the flow rate of viscobromic acid solution is set to 1.2ml / min, potassium nitrite The flow rate is 1.6ml / min. After passing through the mixer, the material flows through a pipeline with an inner diameter of 3mm and a length of 30 meters. After the material is mixed, the...

Embodiment 3

[0044] A peristaltic pump is used as the continuous conveying equipment for liquid materials. The mixer is a static mixer. The liquid material conveying pipeline is a translucent polytetrafluoroethylene tube with an inner diameter of 3mm. The solid-liquid separation of the material adopts a vacuum filtration device, and the liquid raw materials are mixed. The pipeline is immersed in a cold water bath for heat dissipation, and an ultrasonic generator is arranged on the heat dissipation pipeline.

[0045] Adopt mass percentage composition to be that 95.0% potassium nitrite and the mucous acid of mass percentage composition are 98.0% as raw material, first take by weighing 200 grams of mucochloric acid and dissolve in 400 grams of 95% ethanol for subsequent use, the mucous acid solution The volume is about 600ml; in addition, 400g of potassium nitrite is weighed and dissolved in 900g of ethanol water solution with a mass concentration of 45% for later use. The volume of the potass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com