Wide-range optical fiber vacuum sensor with multiple steps and manufacturing method thereof

A vacuum sensor and sensor technology, used in vacuum gauges, instruments, measuring devices, etc., can solve the problem that pressure sensors cannot be distinguished, and achieve the effect of ensuring the accuracy of diaphragm deformation measurement, reducing costs, and expanding the range of high-precision pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

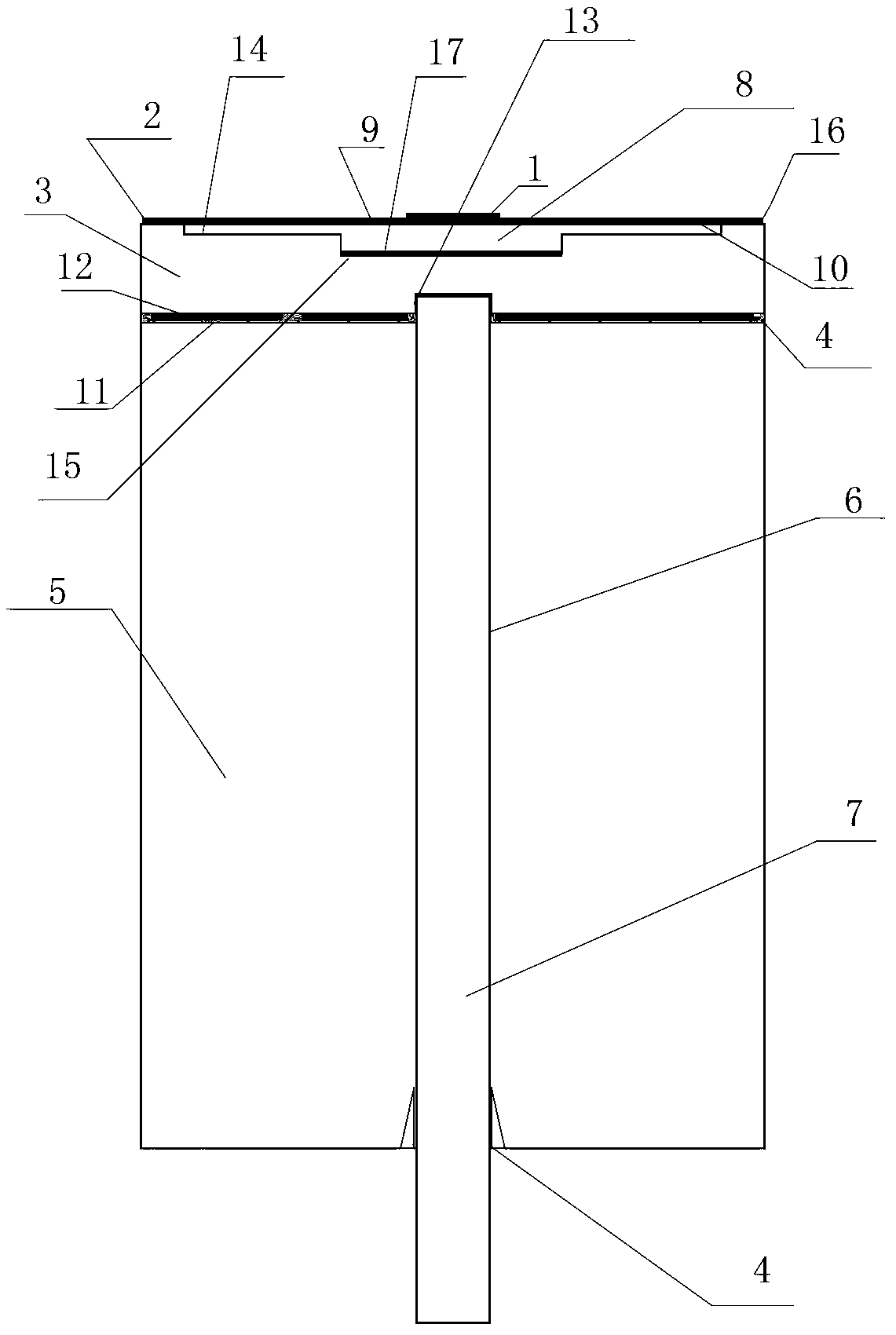

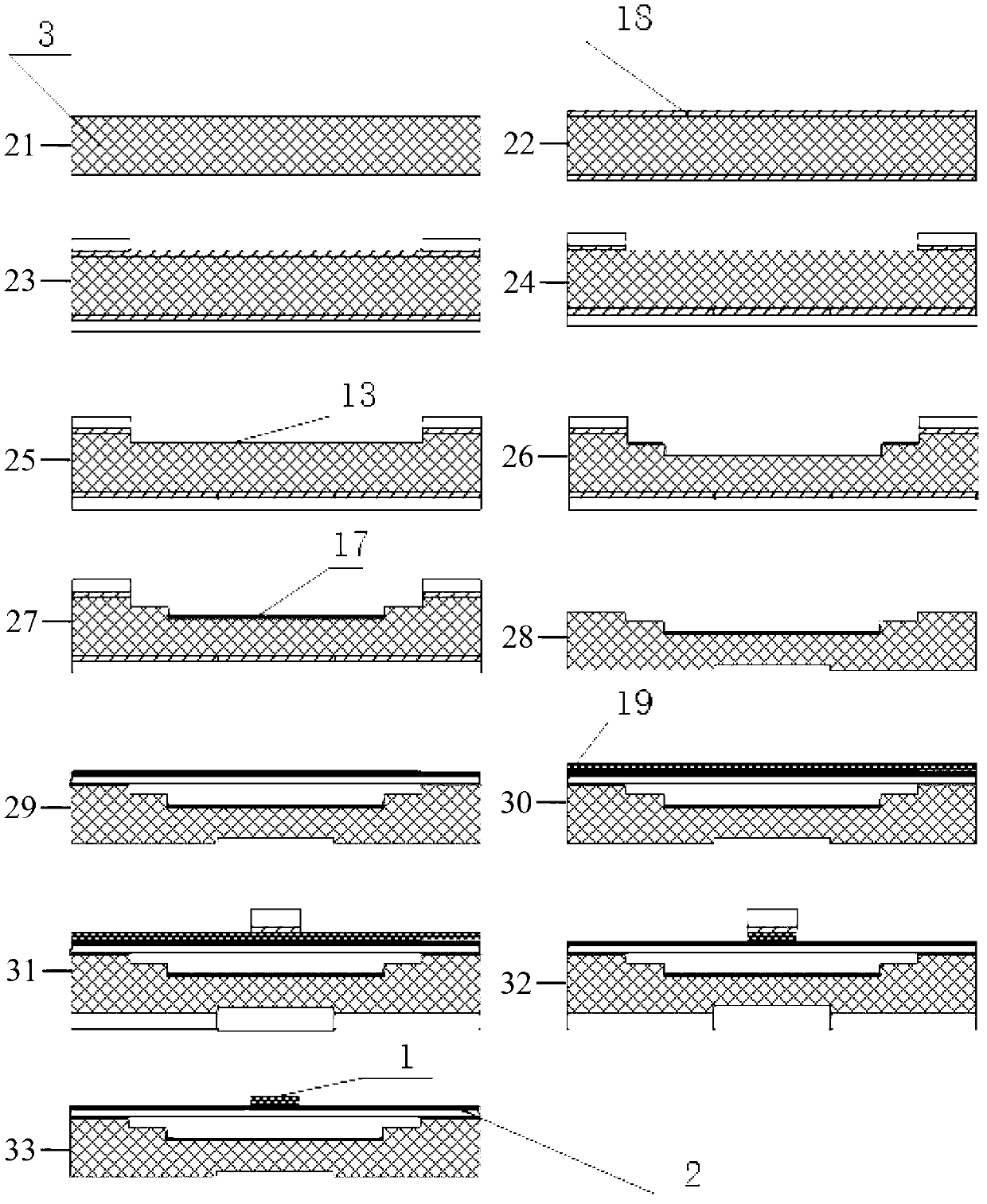

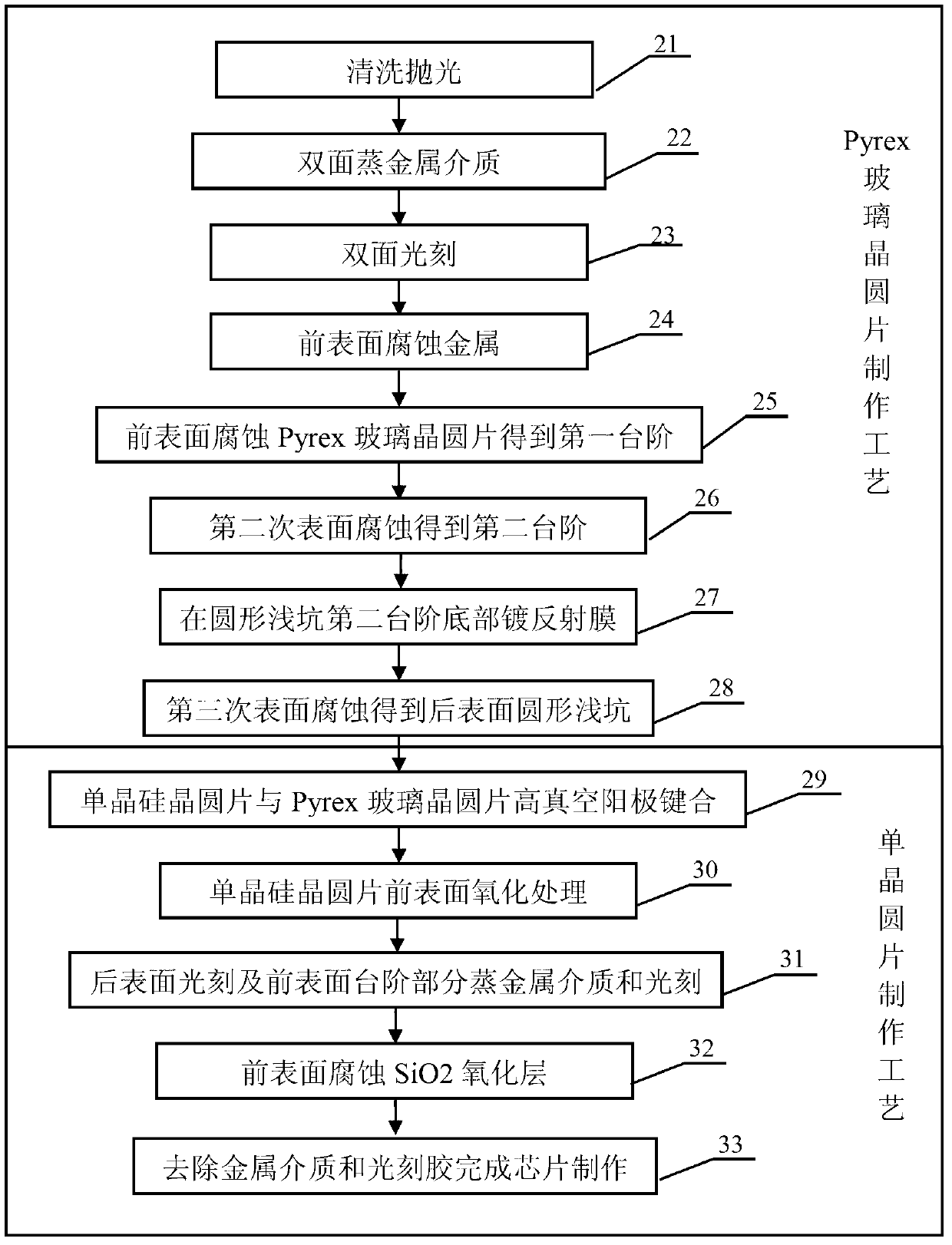

[0048] Embodiment 2: The specific implementation plan of batch production of optical fiber vacuum sensor sensing head by using 4-inch wafer

[0049] The first step 14 of the circular shallow pit array is etched on the front surface of the Pyrex glass wafer 3. The depth of the first step 14 of the circular shallow pit array is 1 μm to 5 μm, and the diameter is 1200 μm to 1900 μm. The pitch of the first step 14 array is 2500 μm; and then it is etched for the second time, and the second step 15 of the circular shallow pit array with a diameter of 500 μm to 800 μm and a depth of 20 μm to 40 μm from the first step 14 is etched out, At the same time, a reflective film 17 with a reflectivity of 10% to 50% is plated on the bottom of the step 15 as the first reflective surface of the Fabry-Perot cavity; after that, the rear surface of the Pyrex glass wafer 3 is etched for the third time, A circular shallow pit with a diameter of 180 μm to 300 μm and a depth of 30 μm to 40 μm is etched ...

Embodiment 3

[0050] Example 3: Optical fiber vacuum sensor step pressure sensing diaphragm disturbance deformation

[0051] Figure 4 For monocrystalline silicon wafers with SiO 2 Schematic diagram of the pressure-sensing diaphragm structure of the oxide layer step. When the external pressure changes, the pressure sensing diaphragm in the sensor head will be disturbed, with a certain amount of disturbance, and the corresponding disturbance amount can be obtained from the disturbance differential equation of the diaphragm:

[0052] w 1 = P ( r 4 64 D 1 - b 2 32 D 1 r 2 ...

Embodiment 4

[0063] Embodiment 4: Demodulation of fiber optic vacuum sensor

[0064] Optical fiber vacuum sensor demodulation system based on white light interference demodulation such as Figure 8 shown. The demodulation process is: the light emitted by the broadband light source 34 (the broadband light source includes white light LED, xenon lamp or halogen lamp) is coupled into the transmission fiber 7, and enters a 2×2 3dB coupler 35, and passes through the fiber 7 from the other end The other output terminal of the 2×2 3dB coupler 35 is connected to the matching liquid for transmission to the sensor 37 . The light signal reflected by the sensor 37 passes through the 2×2 3dB coupler again and then enters the demodulation system 36 to obtain a cavity length demodulation signal. The cavity length information of the fiber optic vacuum sensor can be obtained by calculating the peak position of the spectral envelope. Through the corresponding relationship between the external pressure and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com