LTCC (Low Temperature Co-Fired Ceramic)-based passive LC (inductive-capacitive) humidity sensor

A technology of humidity sensor and inductance, which is applied in the field of sensors, can solve the problems of high cost and complicated process, and achieve the effects of reduced area, controllable precision and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

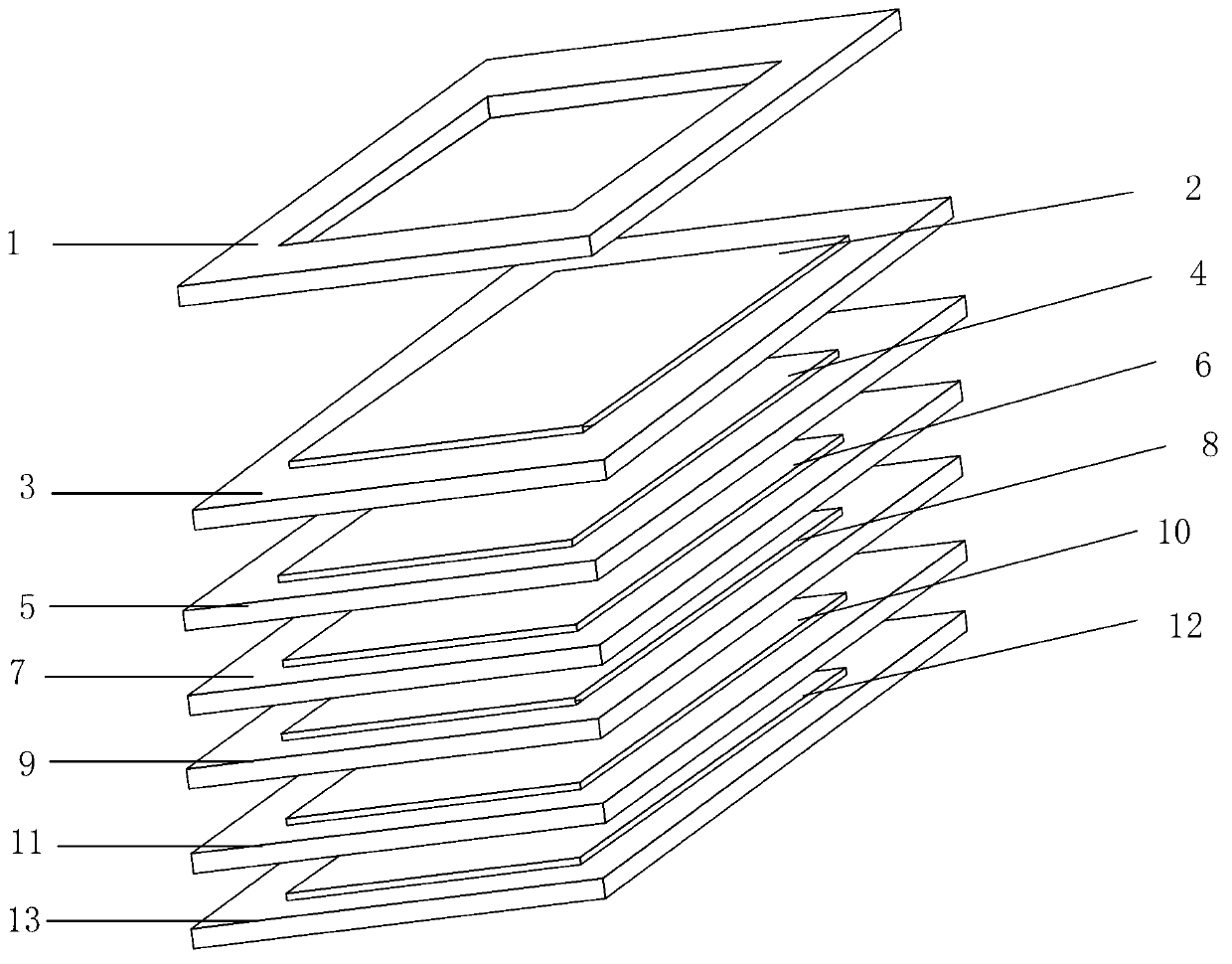

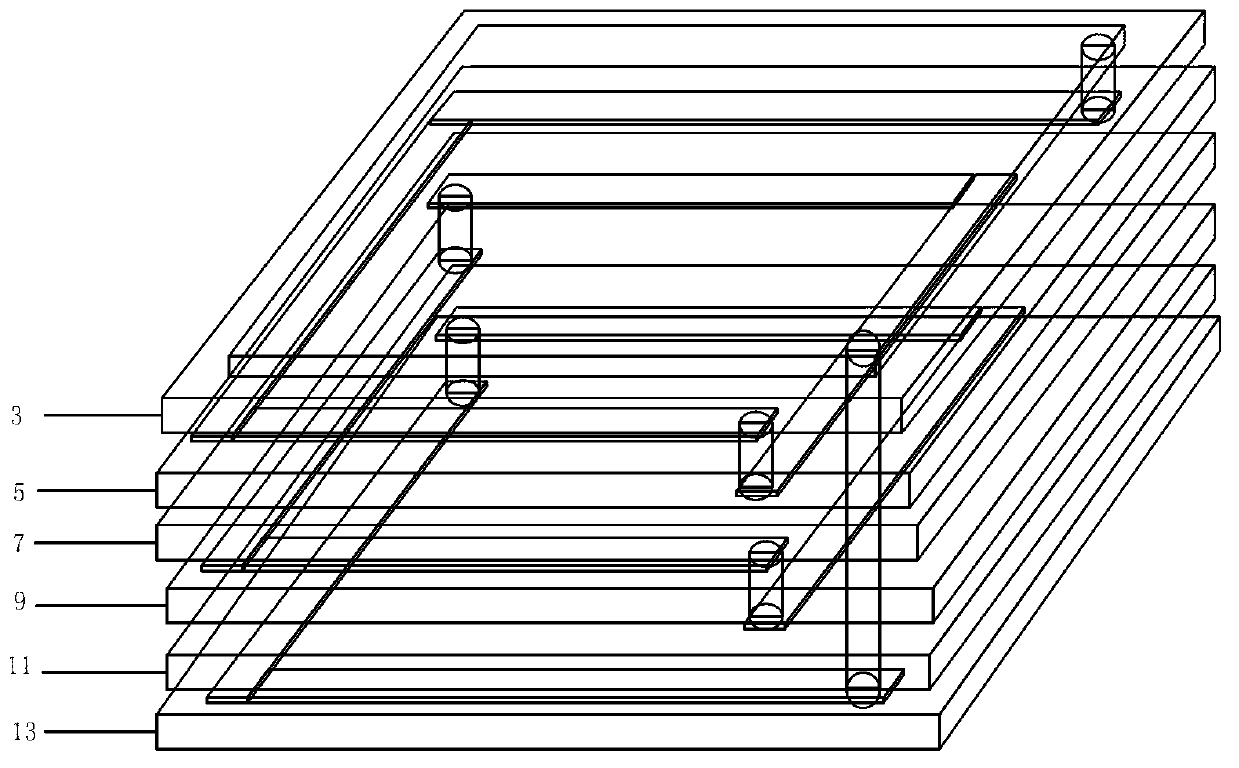

[0025] refer to figure 1 , the system of the present invention includes thirteen layers from top to bottom, among which the odd number layers are all ceramic dielectric layers, using FERRO A6, the relative permittivity is 5.9, the loss tangent is 0.002, the size is 25mm×15mm×0.3mm, and the even number The layers are all metal layer silver, and the thickness is 0.01mm. The first layer of dielectric layer has a window of 20mm×12mm to expose the second layer of interdigitated capacitor metal layer so that the capacitor can sense moisture.

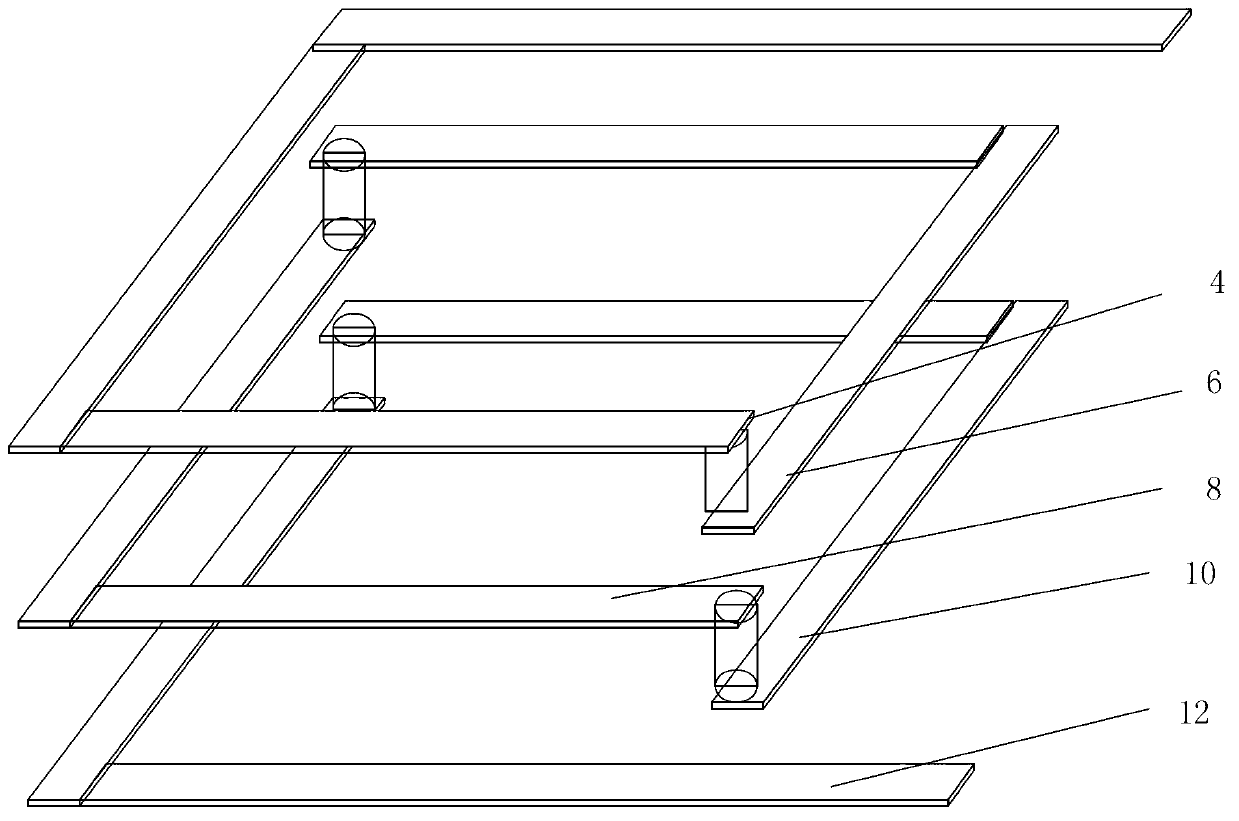

[0026] refer to figure 2 , the fourth, sixth, eighth, tenth and twelfth layers of metal are inductive metal layers. The outer length of each metal coil is 22mm and 12.2mm, and the line width is 0.2mm. The coils of each layer are connected through the through holes in the fifth, seventh, ninth and tenth dielectric layers, and the diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com