Long-acting sustained-release organic nitrogenous fertilizer and manufacturing technology thereof

A slow and controlled release agent, long-acting technology, applied in the form of fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of particle hardness not reaching mechanized seeding, product water solubility reduction, and high energy consumption in the drying process, so as to promote Effects of agricultural mechanization, reduction of moisture at granulation outlet, and improvement of crop yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

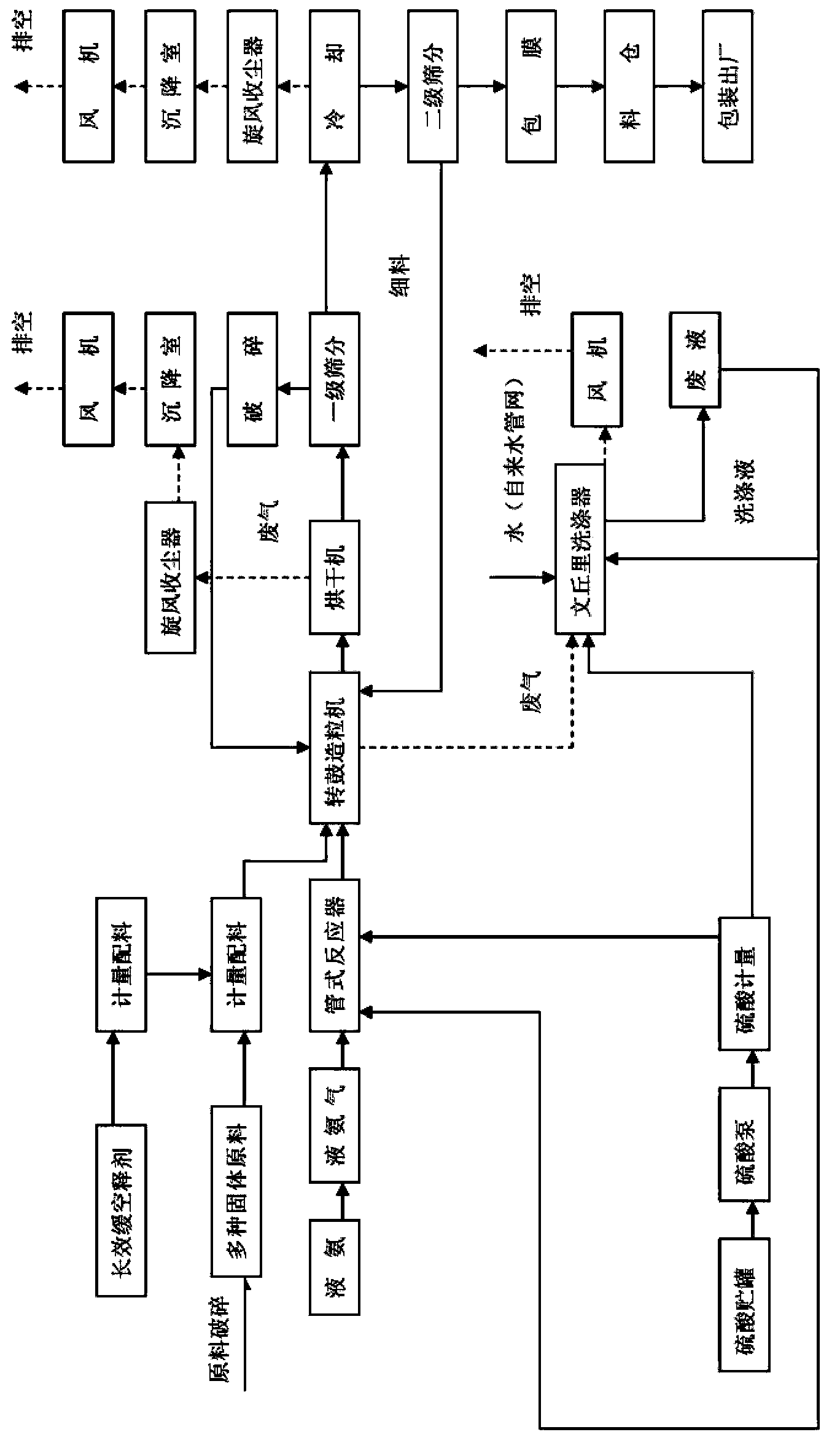

Method used

Image

Examples

Embodiment 1

[0038] Example 1: 50 parts of dried solid raw materials of monosodium glutamate waste residue, 35 parts of urea, 10 parts of ammonium sulfate, 1 part of manganese sulfate, 0.8 parts of long-acting sustained and controlled release agent, 2 parts of liquid ammonia, and 2 parts of 92.5% sulfuric acid.

Embodiment 2

[0039] Example 2: 60 parts of solid raw materials dried from monosodium glutamate waste residue, 35 parts of urea, 8 parts of ammonium sulfate, 1 part of borax, 0.7 parts of long-acting sustained and controlled release agent, 3 parts of liquid ammonia, and 2 parts of 92.5% sulfuric acid.

Embodiment 3

[0040] Embodiment 3: 35 parts of humic acid, 37 parts of urea, 12 parts of ammonium sulfate, 1 part of zinc sulfate, 0.8 part of long-acting sustained and controlled release agent, 2 parts of liquid ammonia, 3 parts of 92.5% sulfuric acid.

[0041] The above-mentioned humic acid is produced by Inner Mongolia Huolinhe Open-pit Coal Industry Co., Ltd. Its main component is organic matter of 54-60%, and the content of humic acid is 46-48%.

[0042] The above-mentioned monosodium glutamate residue was provided by Lvnong Biochemical Engineering Co., Ltd. of Meihua Group, Tongliao City, Inner Mongolia.

[0043] The above-mentioned long-acting sustained and controlled release agent (NAM additive (Ⅲ)) is produced by Shenyang Institute of Applied Ecology, Chinese Academy of Sciences.

[0044] Other raw materials can be purchased from agricultural materials companies all over the country.

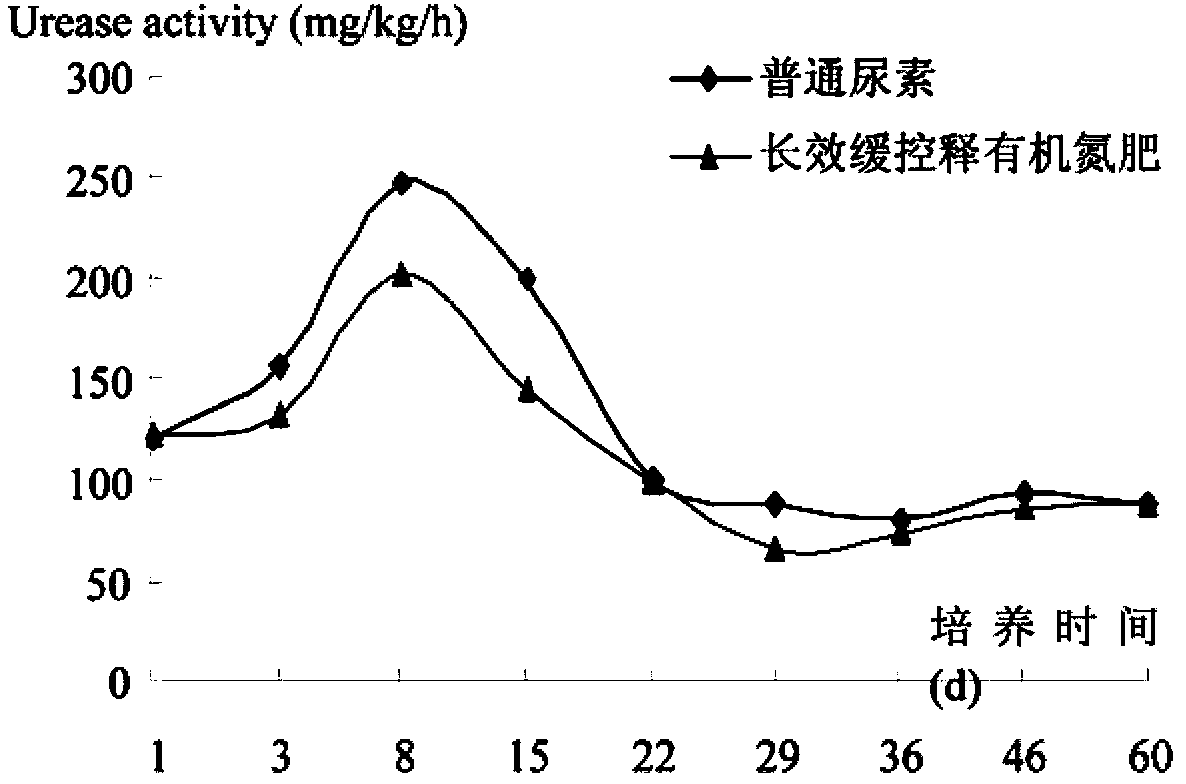

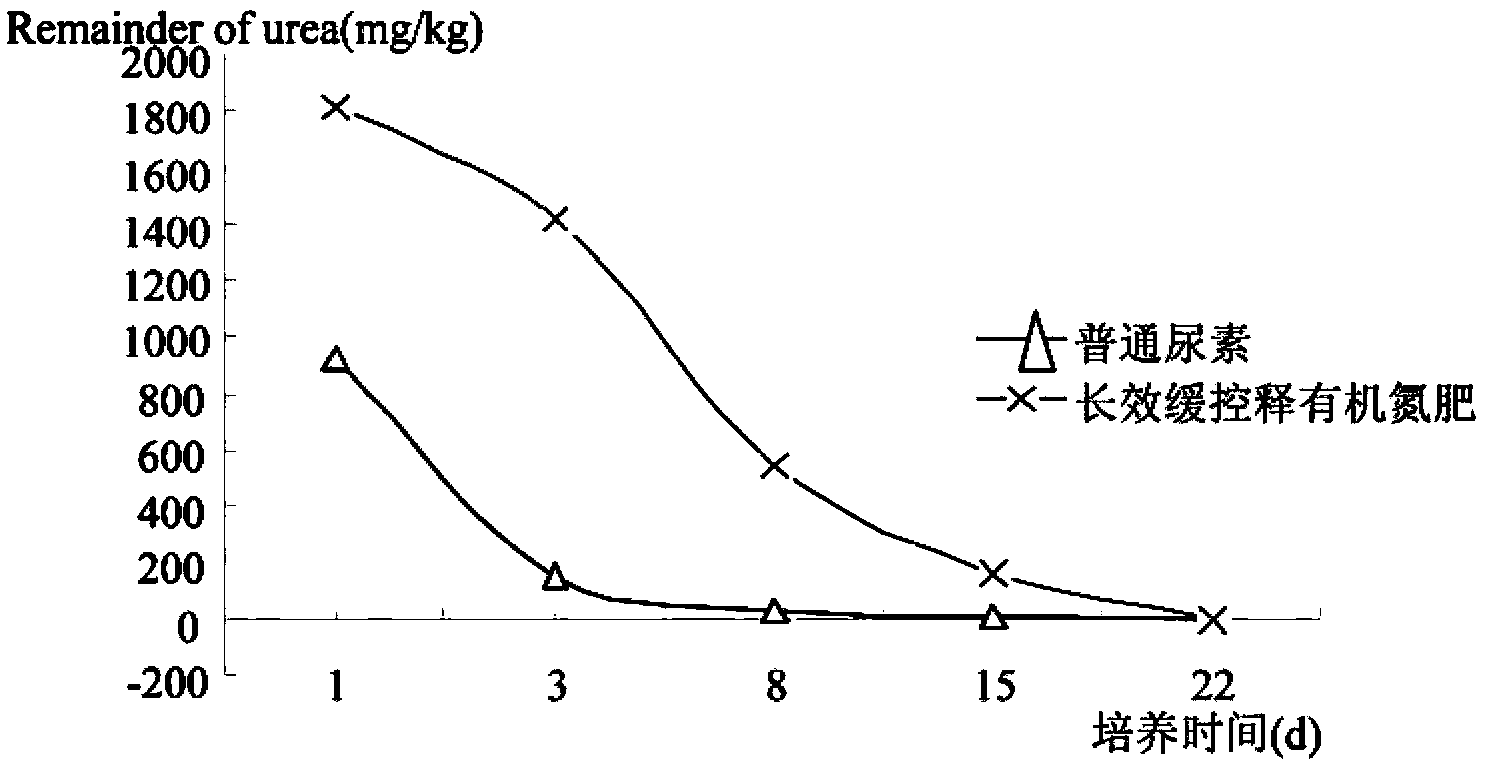

[0045] Depend on figure 1 It can be seen that the embodiment of this organic nitrogen fertilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com