Energy saving and emission reduction method and system for engine tail gas treatment

An energy-saving emission reduction, engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as affecting engine efficiency, waste of energy, atmospheric pollution, etc., to increase maintenance workload and costs, avoid secondary The effect of pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

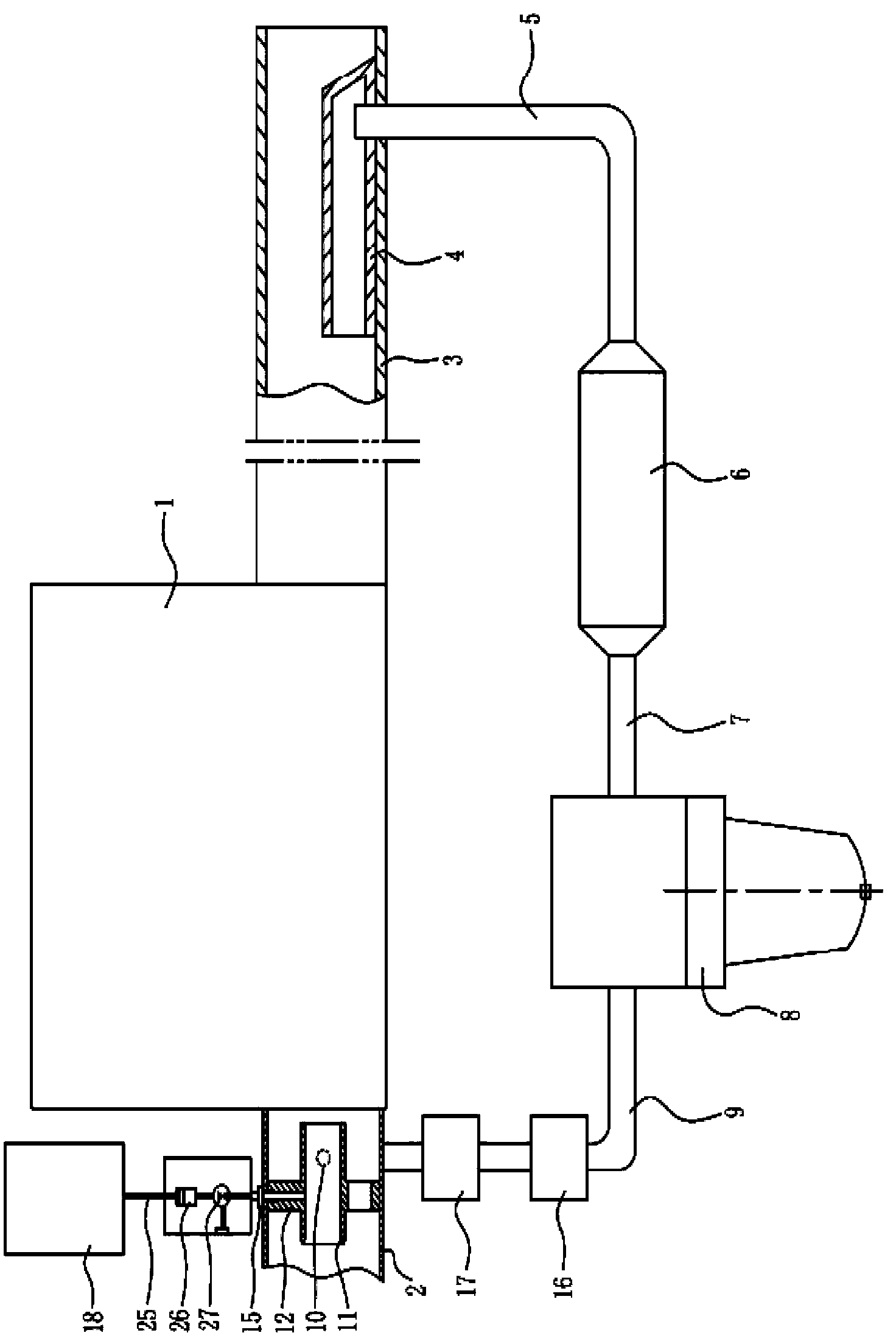

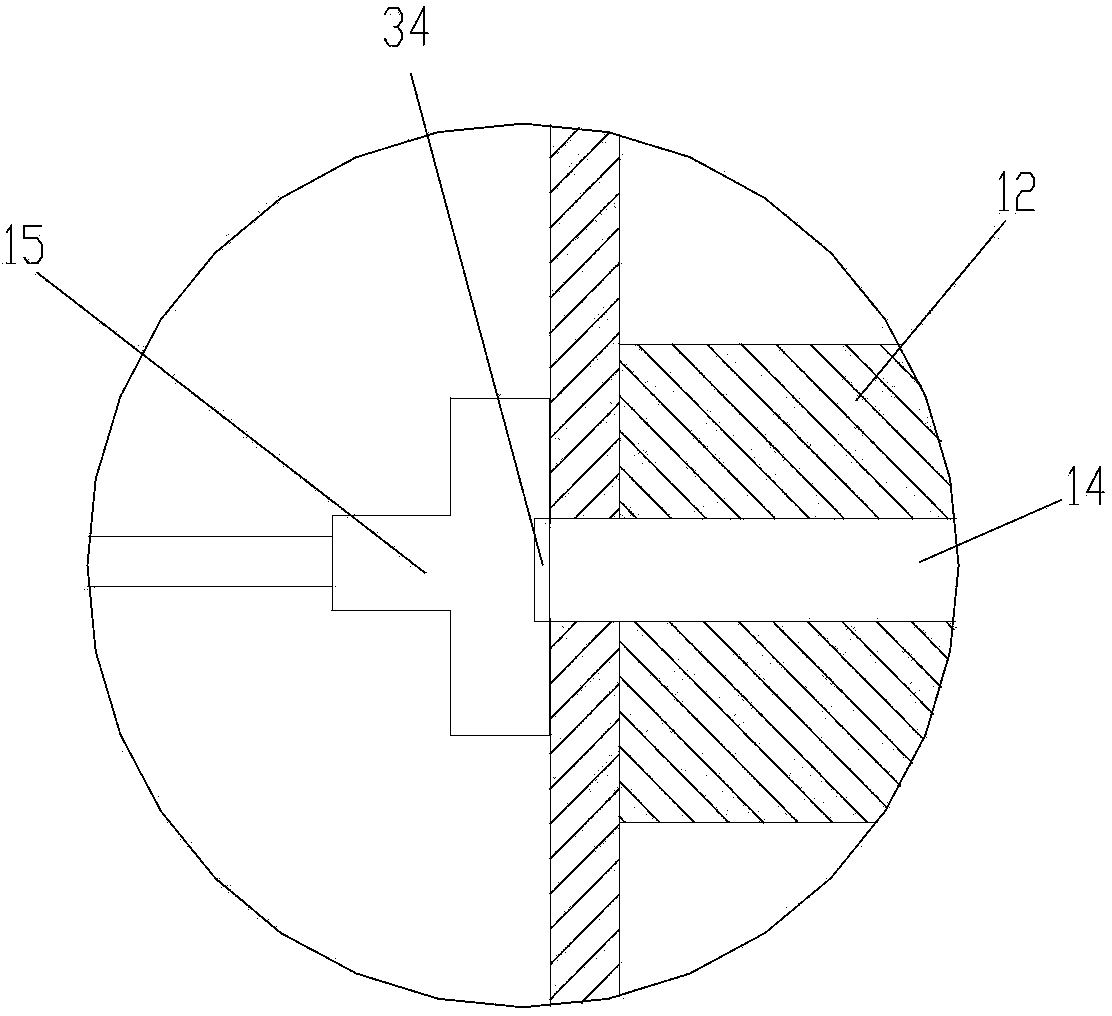

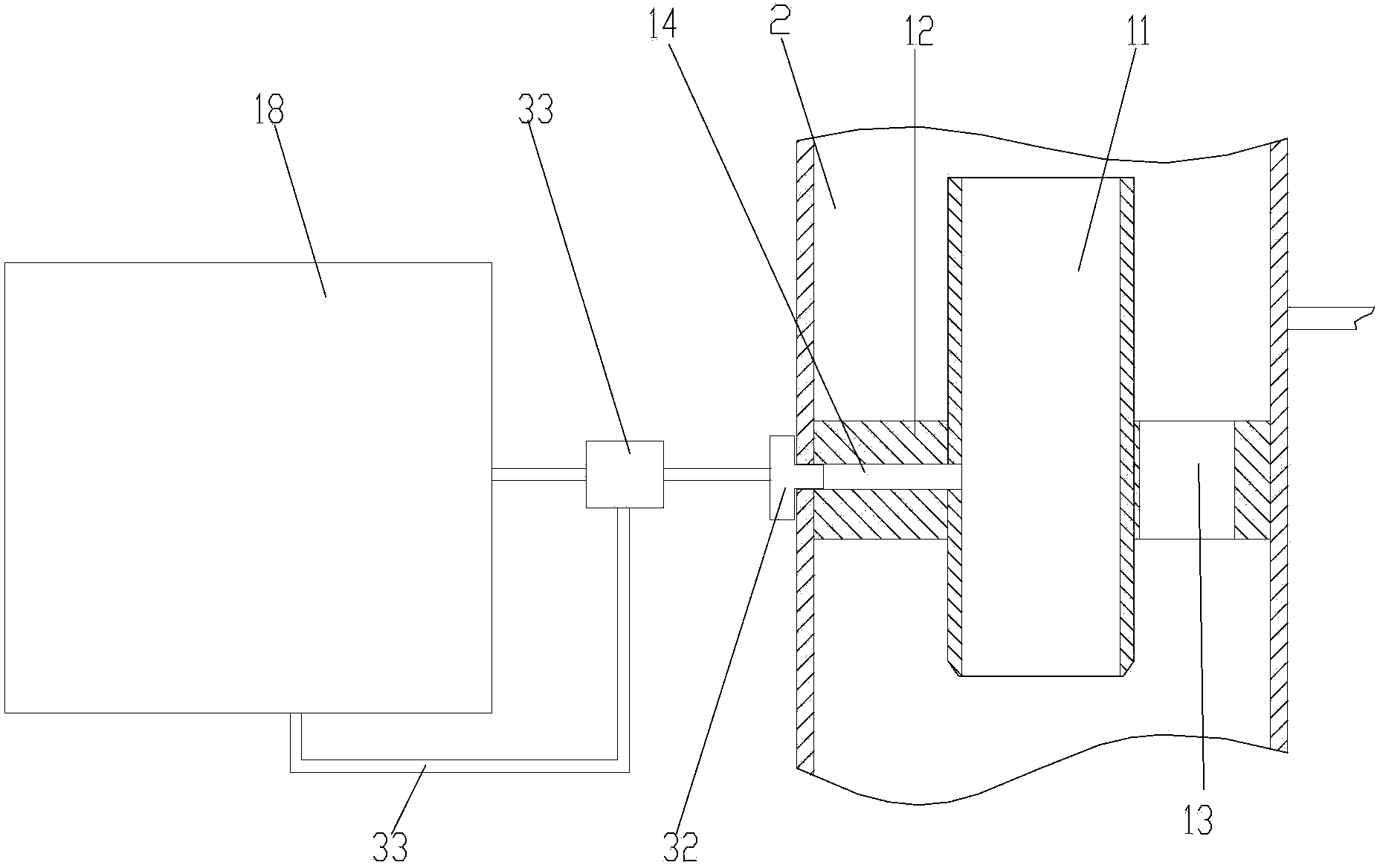

[0031] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view of the structure at the liquid inlet, Figure 4 It is a schematic diagram of the structure of the throttling assembly, Figure 5 for Figure 4 Sectional view along A-A direction, Figure 6 Schematic diagram of the structure of the liquid supply device, Figure 7 It is a cross-sectional view of the air filter structure, as shown in the figure: the fuel evaporation system of this embodiment recovers part of the exhaust gas of the engine 1 and mixes it with the reaction liquid before entering the engine 1 for combustion. The reaction liquid is water or a mixture of water and additives The recovery of part of the exhaust gas of the engine can adopt more recovery methods, such as the recovery of the connection pipe, etc., which belong to the structure that is relatively easy to realize in the existing mechanical connection mode, and will not be repeated here; sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com