Carbon-nitrogen hybrid material of lamellar structure and application thereof

A technology of hybrid materials and carbon-nitrogen materials, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as increasing surface area and no research reports, and achieve the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

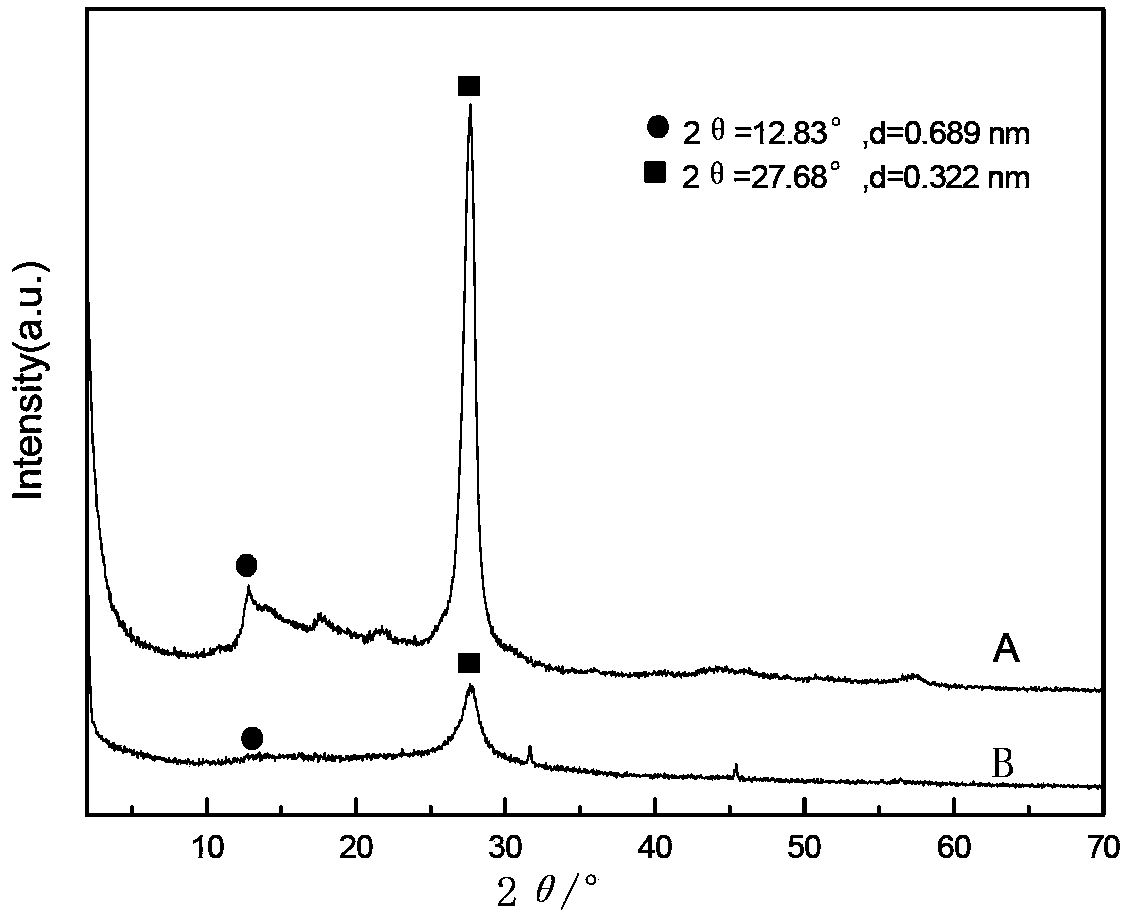

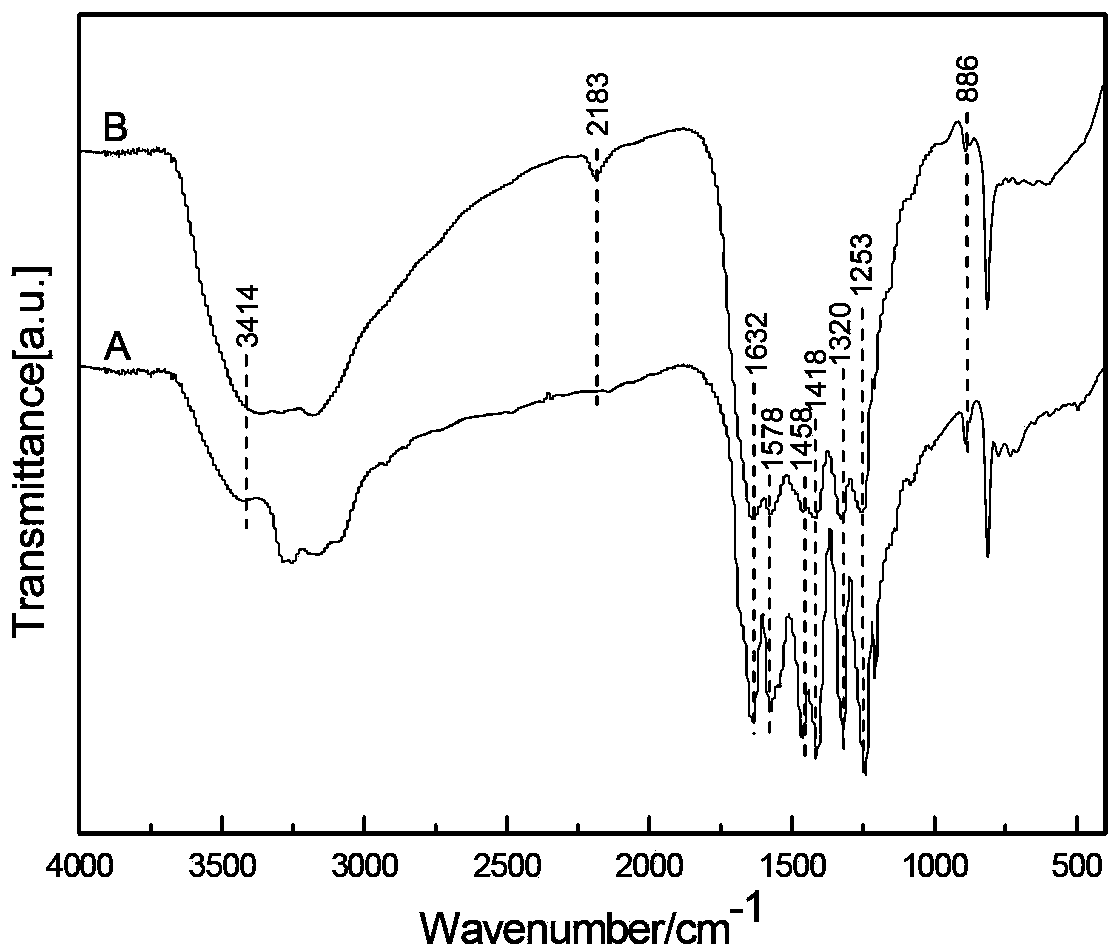

Embodiment 1

[0039] Weigh 2.00g of cyanamide crystals, put them into a small quartz tube, cover the small quartz tube with a large quartz tube, carry out vacuum treatment, and then put the quartz tubes into the tube furnace together, and the quartz tube basically remains in the tube furnace. In the constant temperature zone of the furnace, the temperature of the tube furnace was raised from room temperature to 550 °C at 4 °C / min, and kept for 4 hours, and naturally cooled to room temperature to obtain a light yellow solid powder, which was vacuum-dried at 70 °C for 4 hours, then cooled and ground to obtain a light yellow powder Carbon-nitrogen layered compound composite solid powder. Its X-ray diffraction as figure 1 shown. Its infrared spectrum is as figure 2 shown. Its scanning electron microscope appearance is as image 3 shown. Its transmission electron microscope appearance is as follows Figure 4 shown.

[0040] The catalytic performance test of the material prepared in Examp...

Embodiment 2

[0042] Weigh 2.00g of bentonite (purchased from Zhejiang Changan Renheng Technology Co., Ltd.), add about 100ml of distilled water, and stir magnetically for 10 minutes, then add 2.0g of cyanamide for exchange adsorption, mix well under magnetic stirring, and stir for 30 minutes. Centrifuge, wash with water for 3 times, and dry in a watch glass at 70°C for 12 hours. The obtained white solid particles are ground and packed into bags.

[0043] Weigh 1.00g of the above-mentioned granular material into a small quartz tube, cover it with a large quartz tube, carry out vacuum treatment, and then put the quartz tube into the tube furnace together, and the quartz tube is basically kept in the constant temperature zone of the tube furnace. The tube furnace was heated from room temperature to 550 °C at 4 °C / min, and kept for 4 hours, and naturally cooled to room temperature to obtain a gray solid powder, which was vacuum-dried at 70 °C for 4 hours, then cooled and ground, and the obtaine...

Embodiment 3

[0046] Weigh 2.00g of ammonium saponite (purchased from Ninghai Jiahe Chemical Co., Ltd.), add about 100ml of distilled water, and stir magnetically for 10 minutes, add 2.0g of cyanamide for exchange adsorption, mix well under magnetic stirring, and stir for 30 minutes. Centrifuge, wash with water for 3 times, and dry in a watch glass at 70°C for 12 hours. The obtained white solid particles are ground and packed into bags. Weigh 1.00g of the above-mentioned granular material into a small quartz tube, cover it with a large quartz tube, carry out vacuum treatment, and then put the quartz tube into the tube furnace together, and the quartz tube is basically kept in the constant temperature zone of the tube furnace. The tube furnace was heated from room temperature to 550 °C at 4 °C / min, and kept for 4 hours, and naturally cooled to room temperature to obtain a gray solid powder, which was vacuum-dried at 70 °C for 4 hours, then cooled and ground, and the obtained gray solid powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com