Preparation method of microporous conjugated polymer carbide lithium ion battery anode material

A technology of conjugated polymers and lithium-ion batteries, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large mass loss, difficulty in controlling the pore structure, and affecting the electrochemical performance of negative electrode materials, achieving high specific capacity, Large magnification, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present invention is a method for preparing a negative electrode material of a microporous conjugated polymer carbonized lithium ion battery. The microporous conjugated polymer with a developed three-dimensional pore structure is used as a precursor, and the porous hard carbon negative electrode material is prepared through carbonization. The specific steps are as follows:

[0013] (1) Preparation of microporous conjugated polymers with three-dimensional pore structure: 1,3,5-triethynylbenzene Polymerization to obtain a microporous conjugated polymer with a rigid three-dimensional network structure; or through the Pd(II)-catalyzed Sonogashira-Hagihara coupling copolymerization of the terminal alkynyl group of the monomer and the halogenated group, the ethynyl aromatic compound monomer and Polymerization of halogenated aromatic compound monomers to obtain microporous conjugated polymers;

[0014] (2) Preparation of porous hard carbon by carbonization of microporou...

Embodiment 1

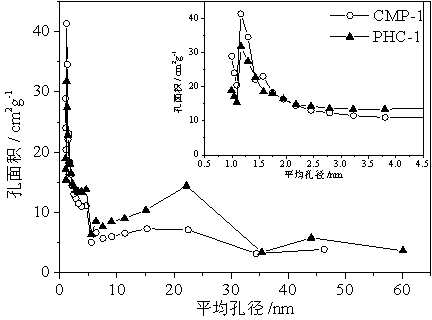

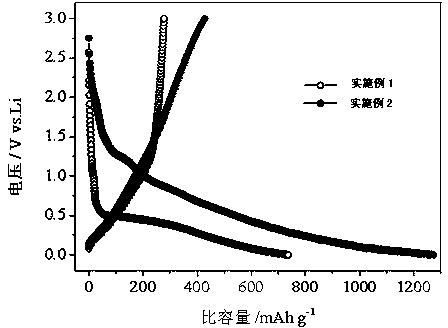

[0028] Weigh 1.2 g of 1,3,5-triethynylbenzene, 0.17 g of bis(triphenylphosphine)palladium dichloride, and 0.044 g of cuprous iodide, and put them into a container containing 8 ml of toluene and 8 ml of triethyl In the amine flask, the mixture was stirred and reacted for 24 h at 70 °C under nitrogen protection to obtain a yellow polymer. The polymer was washed several times with chloroform, acetone, water and methanol to remove unreacted monomers and residual catalysts; then methanol was used as solvent, and CMP was obtained after Soxhlet extraction of the polymer for 72 h. The prepared CMP is pretreated at a high temperature of 200-400° C. for 1-5 hours in a weakly reducing inert atmosphere to pre-carbonize the CMP. Then, raise the temperature to 600-800°C and keep it warm for 2-10 hours to fully carbonize the CMP, and then cool to room temperature to obtain the target product, the microporous conjugated polymer carbonized negative electrode material. Its SEM photos are as ...

Embodiment 2

[0031] Weigh 0.72 g of 1,3,5-triethynylbenzene, 1.74 g of 1,3,5-tris(4-bromophenyl)benzene, 0.16 g of tetrakistriphenylphosphine palladium, and 0.048 g of cuprous iodide, and put into a flask containing 8 ml of toluene and 8 ml of triethylamine, and the mixture was stirred and reacted for 24 h at 80°C under the protection of nitrogen to obtain a yellow polymer. The polymer was washed several times with chloroform, acetone, water and methanol to remove unreacted monomers and residual catalysts; then methanol was used as solvent, and CMP was obtained after Soxhlet extraction of the polymer for 72 h. The prepared CMP is pretreated at a high temperature of 200-400° C. for 1-5 hours in a weakly reducing inert atmosphere to pre-carbonize the CMP. Then, raise the temperature to 600-800°C and keep it warm for 2-10 hours to fully carbonize the CMP, and then cool to room temperature to obtain the target product, the microporous conjugated polymer carbonized negative electrode material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com