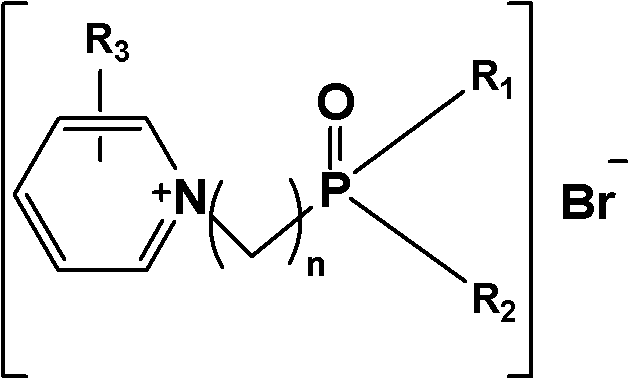

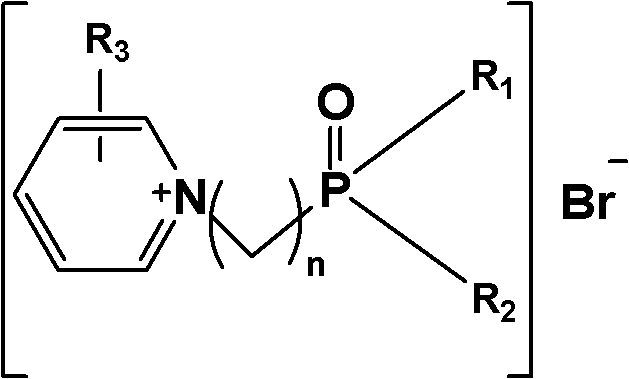

Organic phosphine-functionalized pyridine-based ionic liquid and preparation method thereof

An ionic liquid and pyridine technology, applied in the field of organic phosphine functionalized pyridine ionic liquids and their preparation, can solve the problems of unreported synthesis of pyridine ionic liquids, shorten the reaction time, be easier to purify, and improve the reaction effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 2-picoline (9.3g, 0.1mol) and 2-bromoethyldiphenylphosphine oxide (34.0g, 0.11mol) respectively, add them to a two-neck round bottom flask in turn, add 180mL of toluene, and put them in the microwave In the reactor, magnetic stirring, the temperature is set at 80°C, the power is 350W, and the microwave is continuously irradiated for 60 minutes. During the reaction, it is condensed and refluxed. After the reaction, the product is washed with toluene four to five times to remove unreacted raw materials, and then 80°C After vacuum drying for 3 hours, 23.3 g of light yellow viscous liquid 1-(2-diphenylphosphine oxide) ethyl-2-methylpyridinium bromide salt was obtained, with a yield of 58%.

Embodiment 2

[0021] Take 3-picoline (9.3g, 0.1mol) and ethyl 2-bromoethylphenylphosphonate (30.5g, 0.11mol) respectively, and add them to a two-necked round-bottomed flask in turn, add 180mL of toluene, and put In the microwave reactor, magnetically stirred, the temperature is set at 90°C, the power is 400W, and the microwave is continuously irradiated for 80 minutes. During the reaction, it is condensed and refluxed. After the reaction, the product is washed with toluene four to five times to remove unreacted raw materials, and then 80 After vacuum drying at ℃ for 3 h, 24.8 g of light yellow viscous liquid 1-(2-phenylphosphonic acid ethyl) ethyl-3-methylpyridinium bromide salt was obtained, with a yield of 67%.

Embodiment 3

[0023] Take 4-methylpyridine (9.3g, 0.1mol) and 2-bromoethyldiphenylphosphine oxide (34.0g, 0.11mol) respectively, add them to a two-neck round bottom flask in turn, add 180mL of toluene, and put them in the microwave In the reactor, magnetic stirring, the temperature is set at 100°C, the power is 480W, and the microwave is irradiated continuously for 120min. During the reaction, it is condensed and refluxed. After the reaction, the product is washed with toluene four to five times to remove unreacted raw materials, and then 80°C After vacuum drying for 3 hours, 31.4 g of light yellow viscous liquid 1-(2-diphenylphosphine oxide) ethyl-4-methylpyridinium bromide salt was obtained, with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com