Comeon Electric Venture Coatings Composition

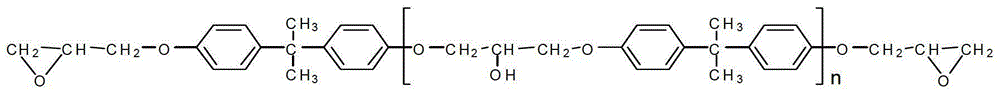

A technology of cationic electrodeposition and composition, applied in the direction of electrophoretic coating, epoxy resin coating, coating, etc., can solve the problems of reduced stability of coating composition, UF filter clogging, etc., and achieve good coating stability and corrosion resistance The effect of excellent performance and excellent spreading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] The present invention is explained in detail below with reference to Preparation Examples, Examples, and Comparative Examples; however, the present invention is not limited thereto. In the examples, "part" and "%" are calculated by mass.

[0112] Preparation of polyester resin (A)

preparation example 1

[0113] Preparation Example 1: Preparation Example of Polyester Resin No. 1 Solution

[0114] 252 parts of soybean oil fatty acid, 222 parts of phthalic anhydride, 207 parts of dodecanedioic acid, 164 parts of trimethylolpropane, 240 parts of 1,6-hexanediol and 48 parts of 2- Butyl-2-ethyl-1,3-propanediol was placed in a reactor equipped with heater, stirrer, nitrogen inlet pipe and rectification column. The mixture was gradually heated to 230 °C under dry nitrogen for esterification. The mixture was maintained at 230°C, subjected to an esterification reaction until the acid value reached 2 mgKOH / g, and then cooled to 170°C. Ethylene glycol monobutyl ether was added thereto to obtain a polyester resin solution No. 1 in which the resin solid content was 80% by mass.

[0115] The resin solid content of the polyester resin No. 1 solution had an acid value of 2 mgKOH / g, an oil content of 24% by weight, a hydroxyl value of 80 mgKOH / g, and a number average molecular weight of 1,750...

preparation example 2 to 7 and comparative preparation example 1 to 4

[0117] Polyester Resin Nos. 2 to 11 solutions were obtained in the same manner as Preparation Example 1 except using the formulation shown in Table 1. The formulation and properties are shown below.

[0118] Table 1

[0119]

[0120] Preparation of amino group-containing epoxy resin (B)

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com