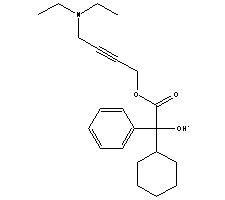

Oxybutynin chloride externally-applied preparation and preparation method thereof

An external preparation, oxybutynin technology, applied in the field of pharmaceutical preparations, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of oxybutynin granule intermediate adopts following prescription:

[0036] Oxybutynin 5g

[0037] Medium Chain Fatty Acid Ester 95g

[0038] Lecithin 20g

[0039] Tween 80 10g

[0040] water 370g

[0041] Prepared fat milk 500g

[0042] Hypromellose 200g

[0043] Sucrose 50g

[0044] Prepared into granules 380g

[0045] Preparation Process:

[0046] 1. Raw and auxiliary materials are pretreated, oxybutynin is crushed to 300 mesh, and other solid auxiliary materials are crushed to 200 mesh;

[0047] 2. Disperse oxybutynin in the medium-chain fatty acid ester, heat and melt, keep the temperature at 70°C, and form the oil phase;

[0048] 3. Weigh lecithin and Tween-80 in water at 75°C, stir and disperse evenly, forming the water phase;

[0049] 4. Slowly add the oil phase into the water phase under low-speed stirring, emulsify until there are no oil droplets on the surface, and then get colostrum;

[0050] 5. High-speed shearing of...

Embodiment 2

[0055] Embodiment 2: the preparation of oxybutynin granule intermediate adopts following prescription:

[0056] Oxybutynin 5g

[0057] soybean oil 55g

[0058] Span 80 10g

[0059] Tween 80 10g

[0060] water 220g

[0061] Made into fat milk 300g

[0062] Sucrose 60g

[0063] Mannitol 60g

[0064] Makes 110g

[0065] Preparation Process:

[0066] 1. Raw and auxiliary materials are pretreated, oxybutynin is crushed to 300 mesh, and other solid auxiliary materials are crushed to 200 mesh;

[0067] 2. Disperse oxybutynin in soybean oil and Span 80, heat and melt, keep the temperature at 80°C, and form the oil phase;

[0068] 3. Weigh Tween-80 and dissolve it in water at 85°C to form the water phase;

[0069] 4. Slowly add the oil phase into the water phase under low-speed stirring, emulsify until there are no oil droplets on the surface, and then get colostrum;

[0070] 5. High-speed shearing of colostrum in a high-pressure homogenizer to obtain fat emulsion;

[...

Embodiment 3

[0075] Embodiment 3: Preparation of dry milk type oxybutynin granules

[0076] The oxybutynin granule intermediate 380g of embodiment 1 gained

[0077] Povidone 180g

[0078] Sodium carboxymethyl starch 395g

[0079] Fragrance 20g

[0080] Make 1000 bags

[0081] Preparation Process:

[0082] 1. Pretreatment of auxiliary materials, passing through a 200-mesh sieve;

[0083] 2. The oxybutynin granule intermediate obtained in Example 1 is mixed homogeneously with other auxiliary materials;

[0084] 3. Test and package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com