A preparation method for oil-soluble nano zirconium dioxide particles in a tetragonal crystal form by adopting an oil-water interface method

A technology of nano-zirconia and oil-water interface method, which is applied in the direction of zirconia, nanotechnology for materials and surface science, nanotechnology, etc. It can solve the problems of low particle purity and large particle size that are not conducive to large-scale industrial production. and other problems, to achieve the effect of good application prospect, simple operation method and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

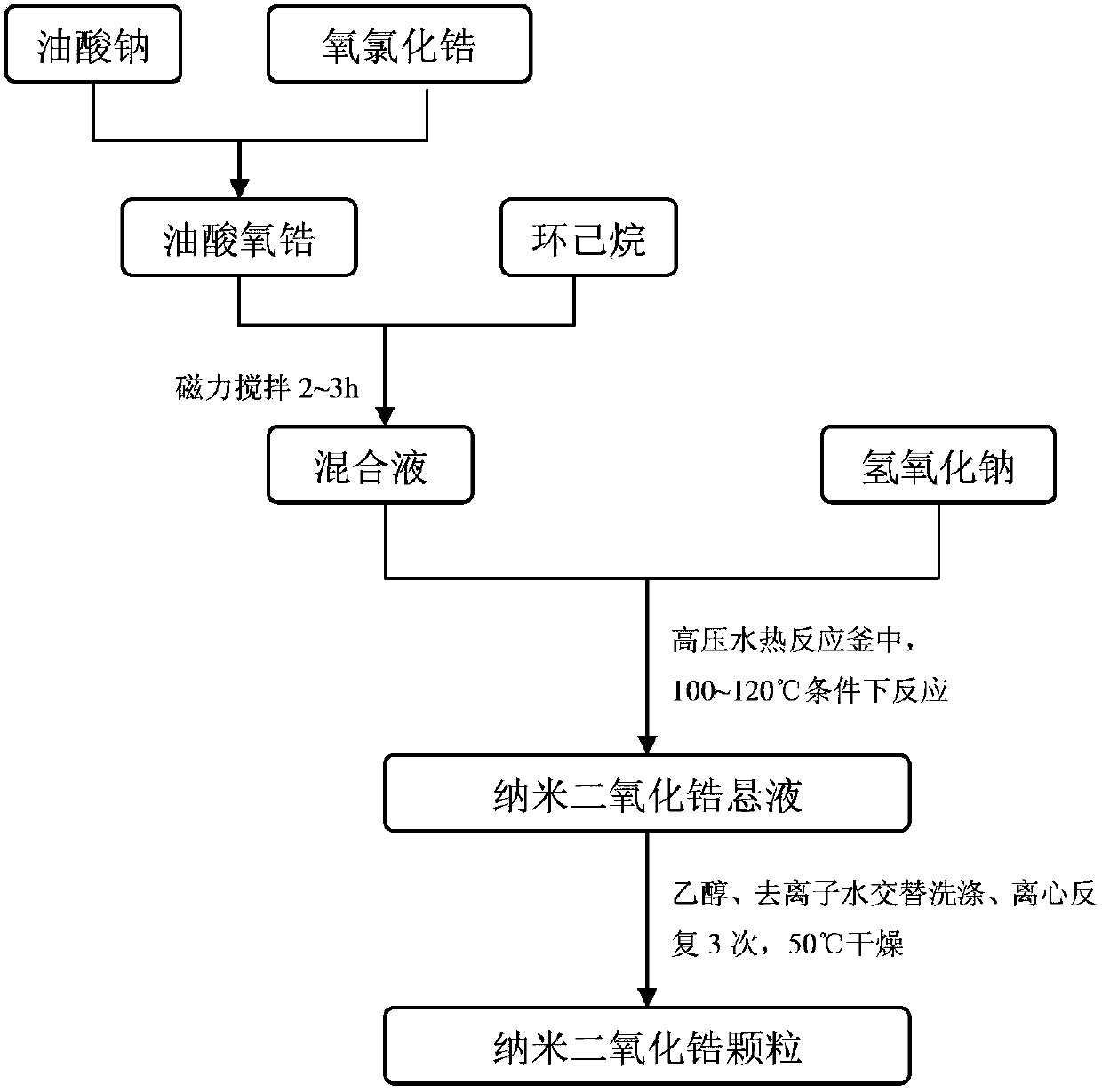

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 1.5222g of sodium oleate and dissolve it in 10ml of deionized water at 45°C. After the sodium oleate was completely dissolved, 5 ml of 0.5 mol / L zirconium oxychloride solution was added to obtain a precipitate. Then add 25ml of cyclohexane to the system, stir magnetically at room temperature for 2-3 hours, until the water phase is colorless and transparent, and the oil phase is milky white, then transfer to a 100ml high-pressure hydrothermal reaction kettle.

[0027] (2) Weigh 3g of sodium hydroxide, dissolve it in 10ml of deionized water, and add it dropwise to the reaction kettle.

[0028] (3) Place the reaction kettle in a blast drying oven and react at 100°C for 24 hours.

[0029] (4) After the reaction, after the high-pressure hydrothermal reactor is naturally cooled to room temperature, wash with absolute ethanol, centrifuge at 10,000rpm for 15min to remove the supernatant, then wash with deionized water, and centrifuge at 10,000rpm for 15min Remove th...

Embodiment 2

[0031] (1) Weigh 1.5222g of sodium oleate and dissolve it in 10ml of deionized water at 45°C. After the sodium oleate was completely dissolved, 5 ml of 0.5 mol / L zirconium oxychloride solution was added to obtain a precipitate. Then add 25ml of cyclohexane to the system, stir magnetically at room temperature for 2-3 hours, until the water phase is colorless and transparent, and the oil phase is milky white, then transfer to a 100ml high-pressure hydrothermal reaction kettle.

[0032] (2) Weigh 3g of sodium hydroxide, dissolve it in 10ml of deionized water, and add it dropwise to the reaction kettle.

[0033] (3) Place the reaction kettle in a blast drying oven and react at 120°C for 24 hours.

[0034] (4) After the reaction, after the high-pressure hydrothermal reactor is naturally cooled to room temperature, wash with absolute ethanol, centrifuge at 10,000rpm for 15min to remove the supernatant, then wash with deionized water, and centrifuge at 10,000rpm for 15min Remove th...

Embodiment 3

[0036] (1) Weigh 1.5222g of sodium oleate and dissolve it in 10ml of deionized water at 45°C. After the sodium oleate was completely dissolved, 5 ml of 0.5 mol / L zirconium oxychloride solution was added to obtain a precipitate. Then add 25ml of cyclohexane to the system, stir magnetically at room temperature for 2-3 hours, until the water phase is colorless and transparent, and the oil phase is milky white, then transfer to a 100ml high-pressure hydrothermal reaction kettle.

[0037] (2) Weigh 2g of sodium hydroxide, dissolve it in 10ml of deionized water, and add it dropwise into the reaction kettle.

[0038] (3) Put the reaction kettle in a blast drying oven and react at 120°C for 72 hours.

[0039] (4) After the reaction, after the high-pressure hydrothermal reactor is naturally cooled to room temperature, wash with absolute ethanol, centrifuge at 10,000rpm for 15min to remove the supernatant, then wash with deionized water, and centrifuge at 10,000rpm for 15min Remove th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com