Method and device for producing active lime powder from calcined limestone

A technology for calcining limestone and limestone powder, which is applied in lime production, etc., can solve the problems of high maintenance cost, low thermal efficiency, and low raw overburning rate, and achieve the effects of high degree of automation, expanded production scale, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

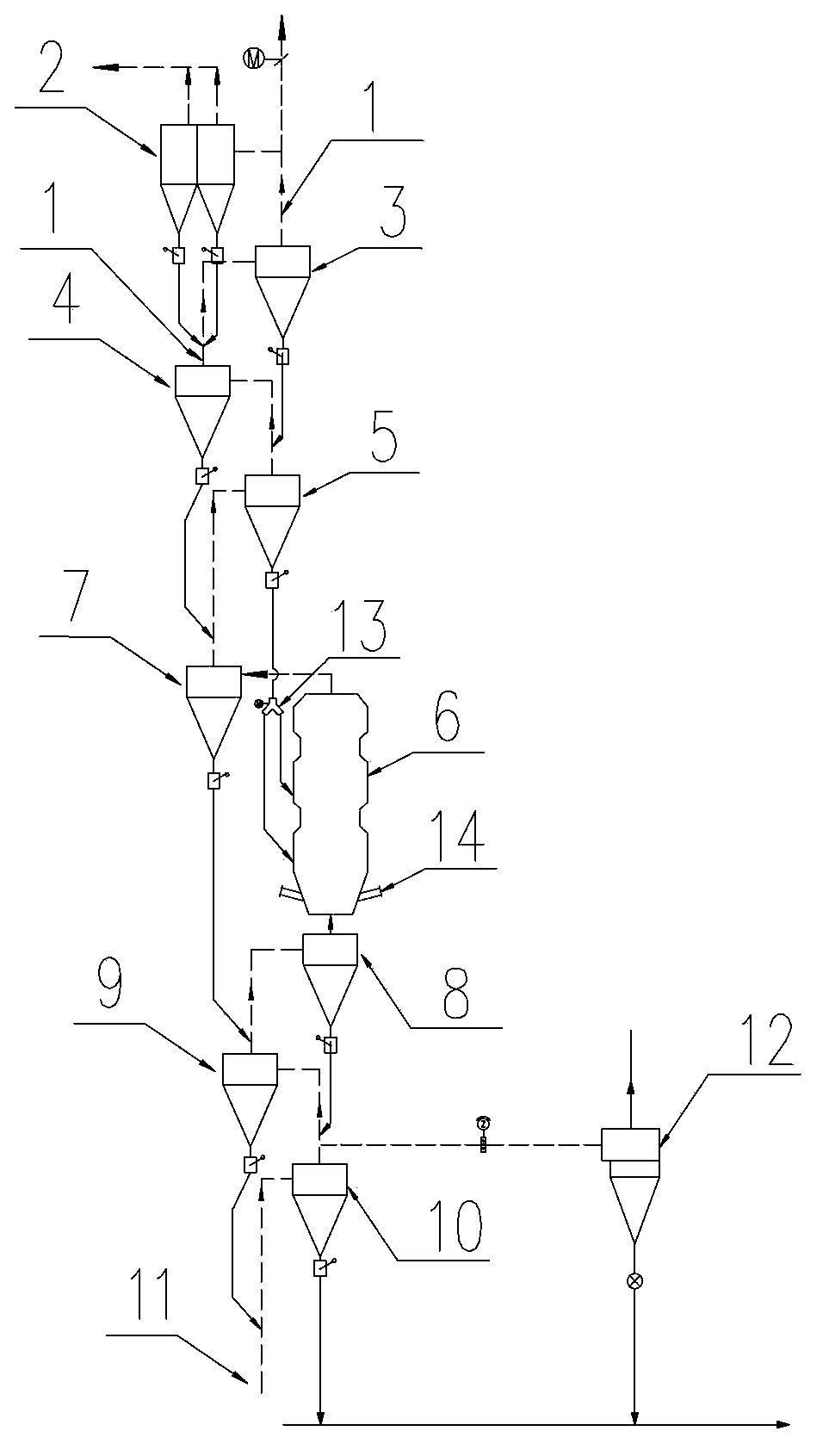

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] The invention discloses a method for producing active lime powder by calcining limestone, which comprises the following steps:

[0019] 1) Using limestone as raw material, crushing and grinding to obtain limestone powder;

[0020] 2) The limestone powder is preheated by a suspension preheating system, and after preheating, the limestone powder is heated by a combustion decomposition furnace to further absorb heat and decompose;

[0021] 3) Cooling the thermally decomposed material in step 2) through a suspension cooling system to obtain active lime powder.

[0022] The fuel used in the combustion decomposition furnace is any one of coal, natural gas, fuel oil and petroleum coke.

[0023] See figure 1 , a device for producing active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com