Liquid flow frame structure for flow cell and electric pile formed by flow cell

A technology of liquid flow battery and liquid flow frame, which is applied in the direction of fuel cell grouping, fuel cell components, fuel cells, etc., which can solve problems such as uneven voltage, large flow resistance, and increased battery voltage difference, and achieve pressure and flow uniformity, improve energy efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings.

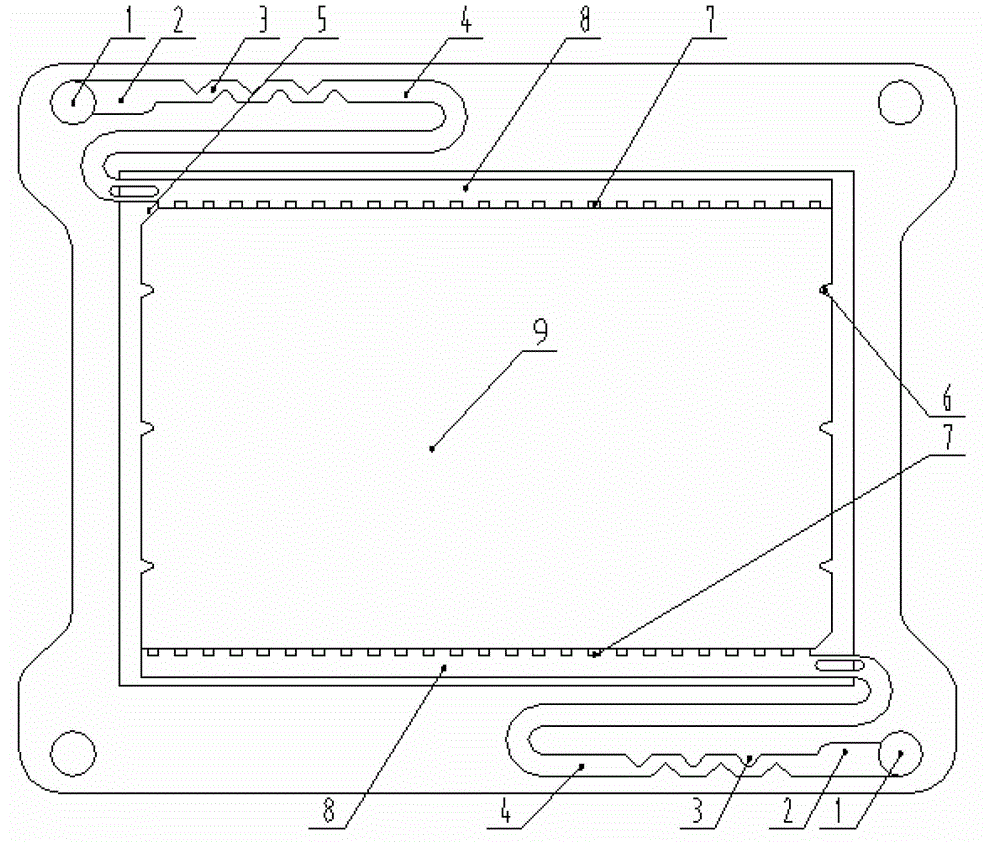

[0023] Such as figure 1 As shown, the flow battery flow frame of the present invention includes a positive electrode flow frame and a negative electrode flow frame. The main flow pipe located inside the liquid flow frame and connected to the external liquid storage tank. The inlet of the main flow pipe is the liquid inlet and outlet 1 provided on the surface of the liquid flow frame. The section 3 and the serpentine channel 4 communicate with the distribution channel 8 , and the distribution channel 8 communicates with the reaction zone 9 . A distribution grid 7 is arranged on the side of the distribution channel 8 close to the reaction zone 9 . The tops of both sides of the reaction zone 9 are provided with flow blocking blocks 5 , and the two sides of the reaction zone ( 9 ) are provided with flanges 6 .

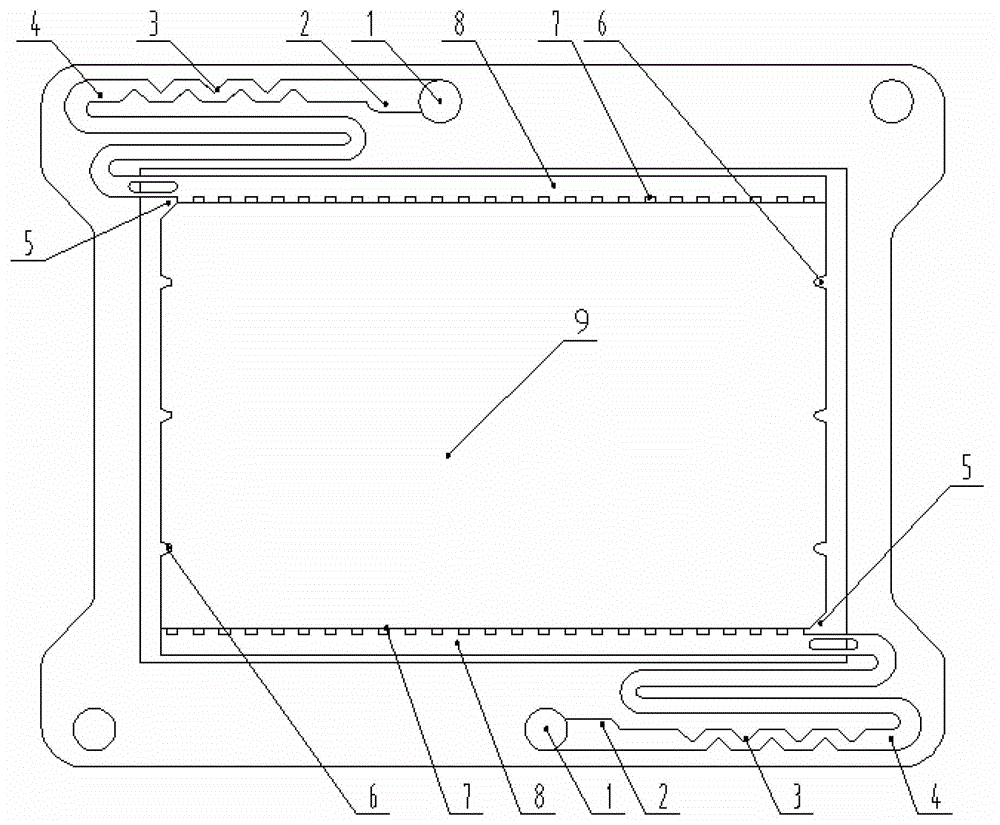

[0024] figure 2 It is another embodiment of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com