Spore powder collection method, spore powder collection apparatus and brushing machine

A collection device and spore powder technology, which is applied in the direction of cyclone device, chemical instrument and method, biochemical cleaning device, etc., can solve the problems of increased separation burden, high stirring energy consumption, low production efficiency, etc., and achieve the reduction of spore powder Content, improve the separation effect, the effect of compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

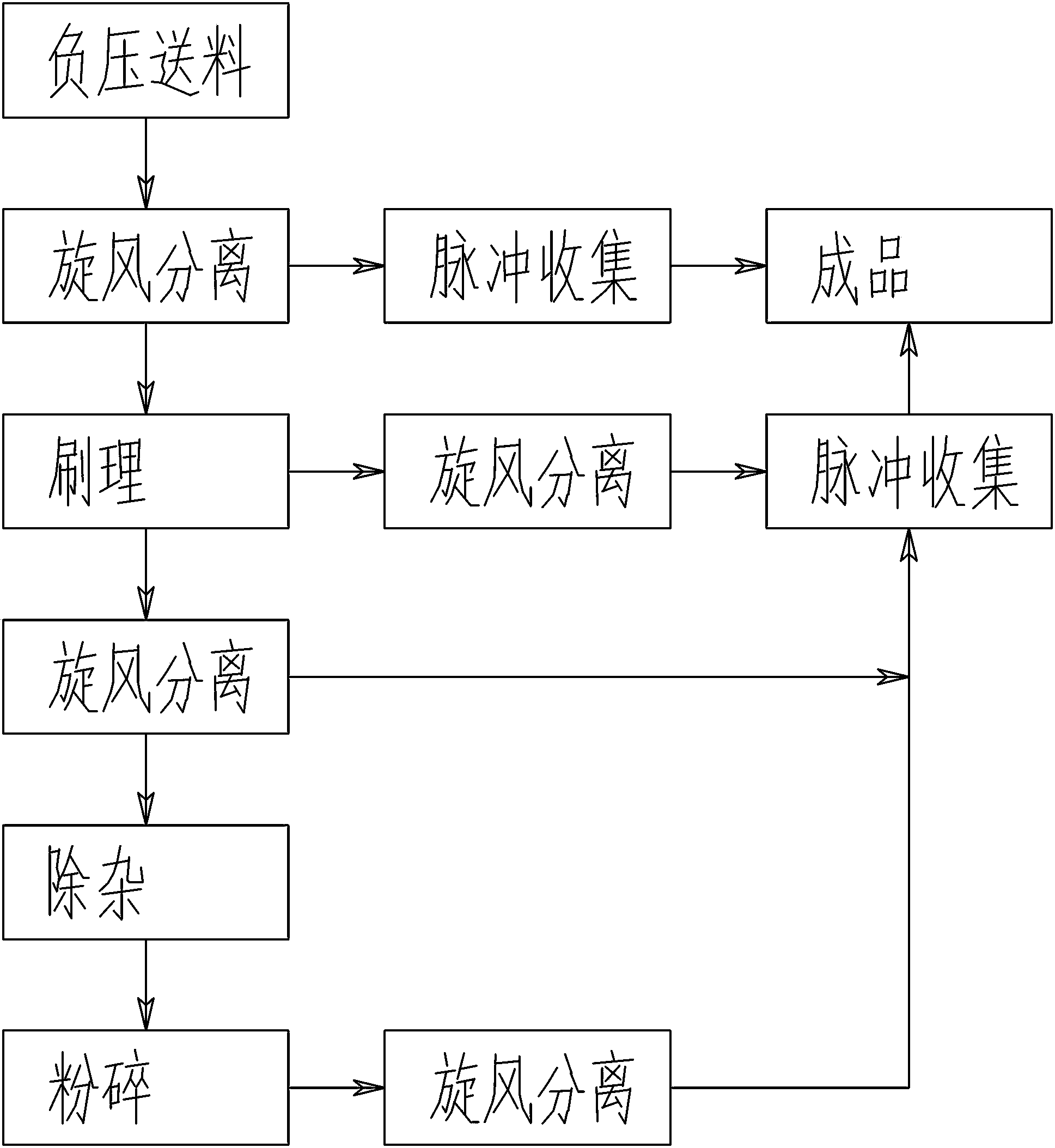

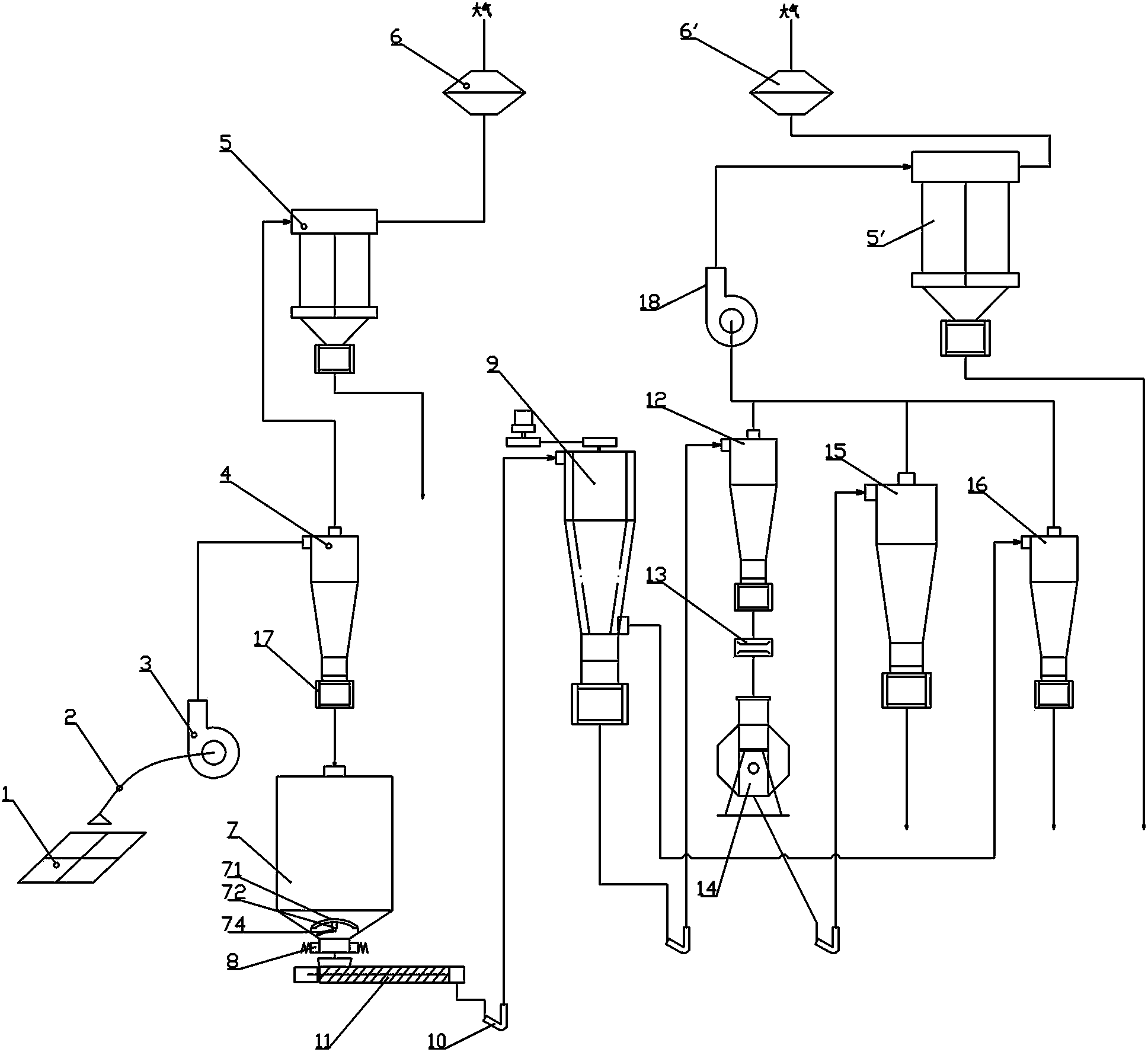

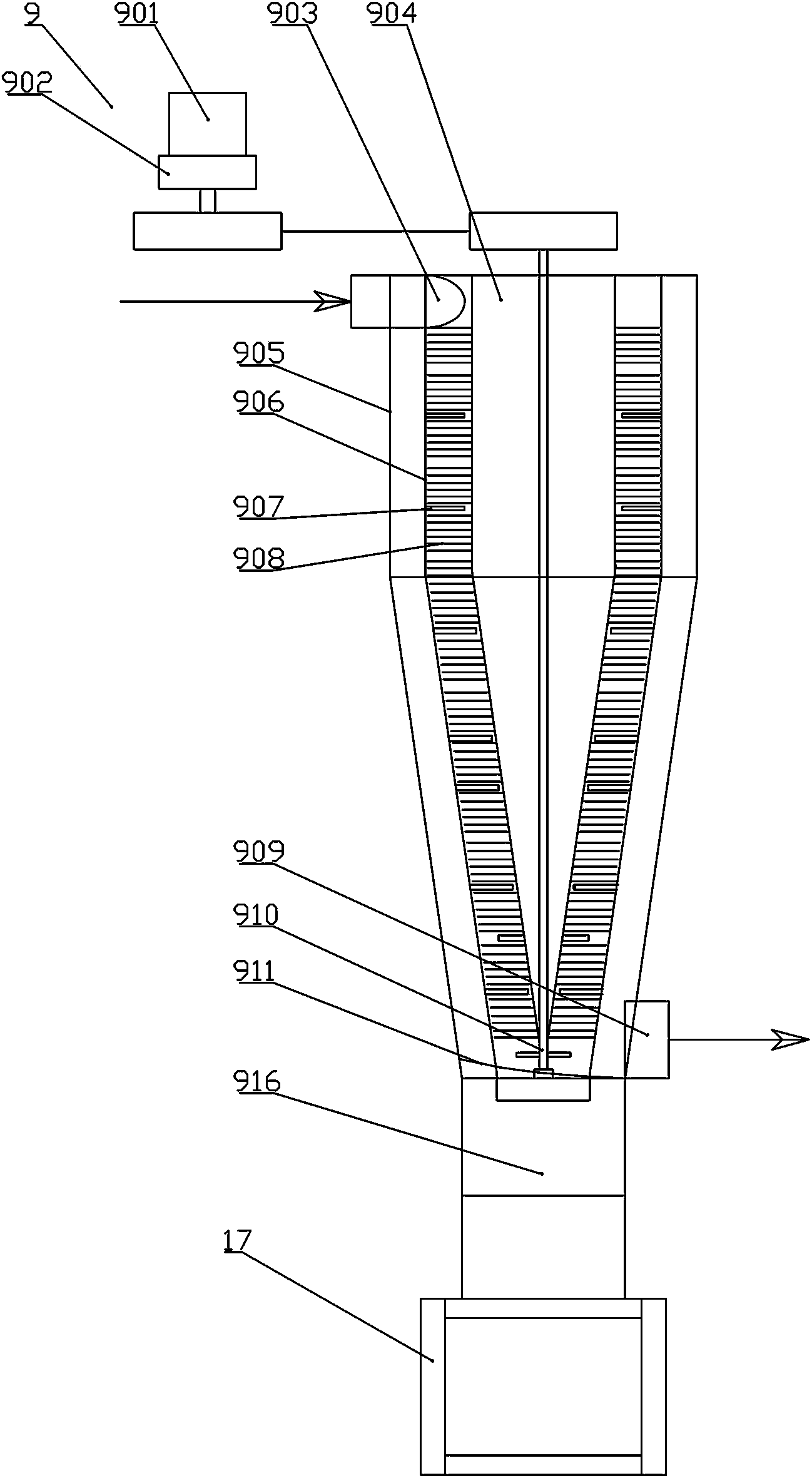

[0044] Such as figure 1 , 2 , A method for collecting spore powder, including the following steps:

[0045] 1. After drying, the fungus bed 1 is sent to the first cyclone 4 by the suction and transport collector 3, the light material is collected by the bag of the pulse dust collector 5 to obtain spore powder, and the air is discharged into the atmosphere through the hood 6. In this example, pulse The cloth bag in the dust collector 5 is preferably a special filter bag of 350-400 mesh; the spore powder separated in the first step has the highest purity. Therefore, the volume of solid medium particles is relatively large and the separation is easier. At this time, the air volume of the first cyclone 4 can be adjusted to the maximum compared with other cyclones.

[0046] 2. The heavy material in the first cyclone separator 4 is transported to the storage bin 7, and sent to the next process through the vibrating discharger 8 and the tubular feeder 11, the vibrating discharger 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com