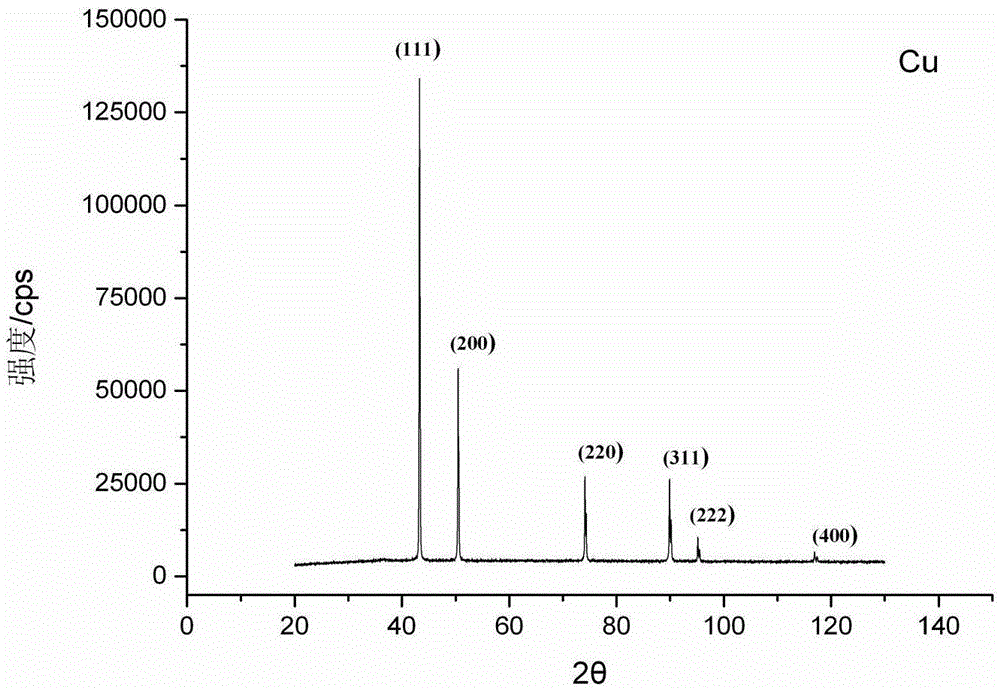

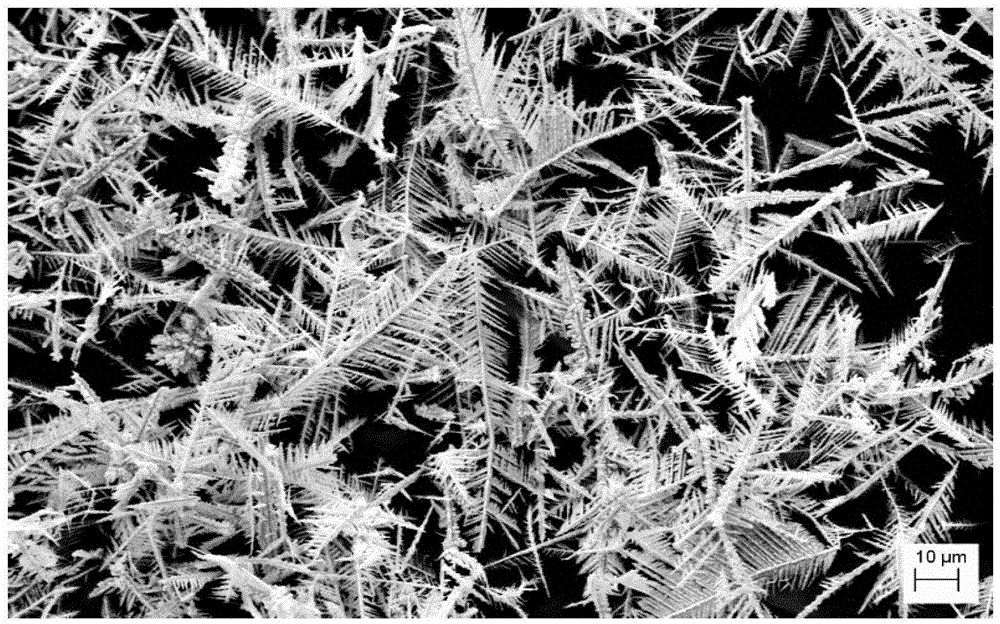

A kind of preparation method of two-dimensional feathery copper powder under ammonia condition

A feather-like, copper powder technology, applied in the field of metal materials and powders, can solve the problems of electrolytic copper powder production constraints, relatively low production efficiency, etc., to facilitate preservation and follow-up research, narrow particle size distribution range, easy reagent raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The prepared electrolyte is added to the electrolytic cell, the cathode is vented with nitrogen to remove oxygen, heated in a constant temperature water bath until the temperature of the electrolyte is 20-75°C, and electrolyzed at 0.6-5V DC to obtain copper powder. The specific electrolysis conditions and the morphology of the obtained copper powder are shown in Table 1 (the additives are cetylpyridine bromide, isopropyl myristate, sodium dodecylbenzenesulfonate, isooctylphenol polyoxyethylene ether, Tween, sodium polystyrene sulfonate, lauramide propyl hydroxysultaine, decyl glucoside, triethanolamine and urotropine).

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com