Safety protection and control system for closed space in acidic etchant gas environment

A technology for corrosive gas and safety protection, applied in heating and ventilation control systems, heating and ventilation safety systems, space heating and ventilation, etc., to achieve long storage life, mildew-proof on-site replacement, and good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

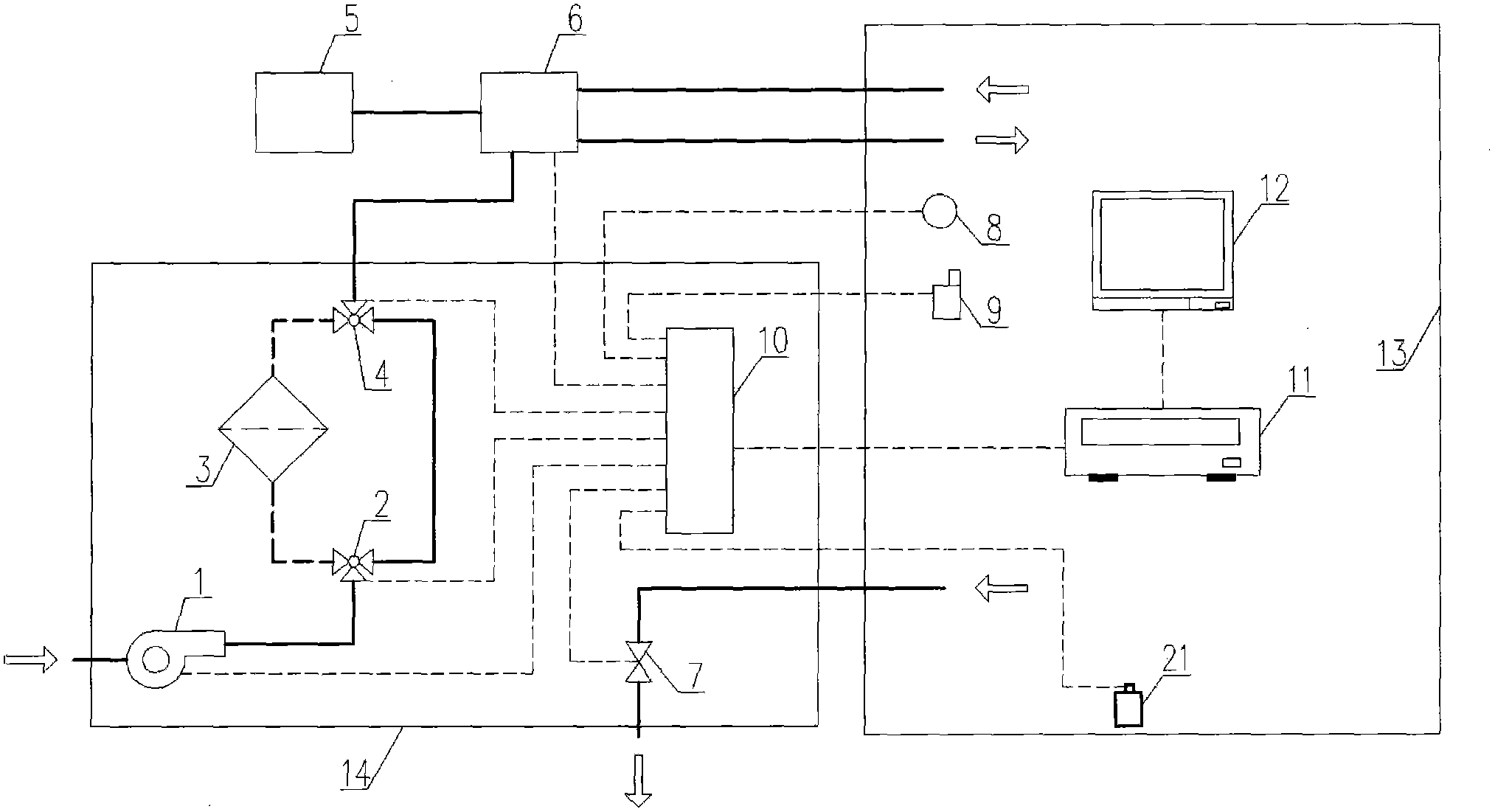

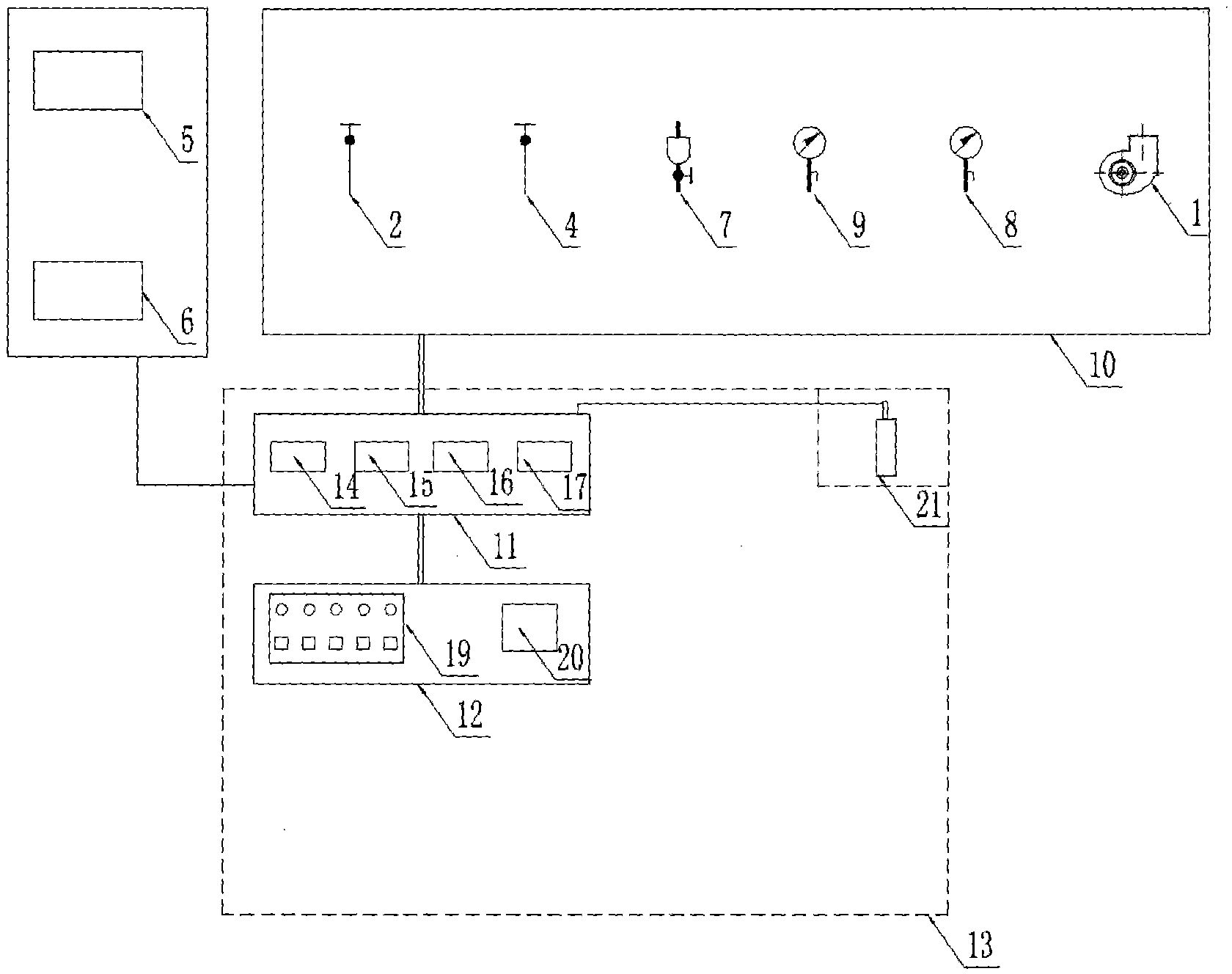

[0050] Example 1 Air supply mode for filtering acidic corrosive gas

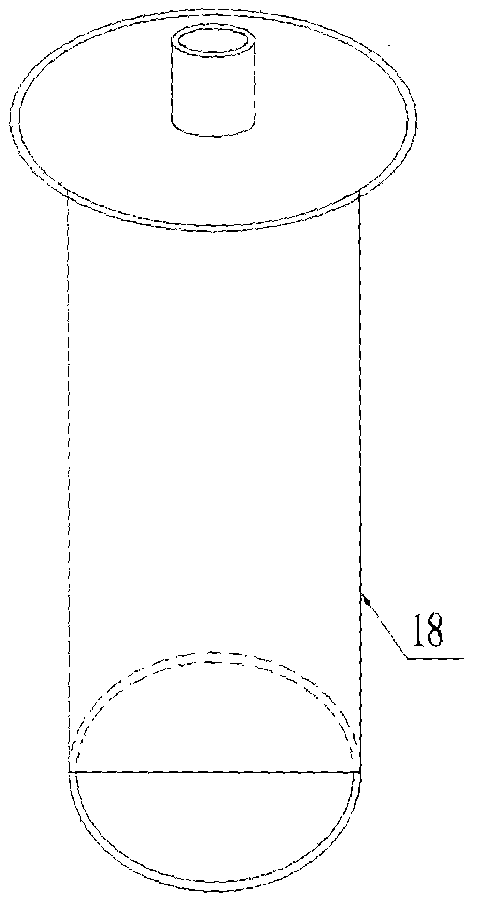

[0051] The confined space 13 is in an environment of acidic corrosive gas, and when overpressure ventilation is required, an instruction is issued from the control panel 19 or the touch screen 20 of the control center 12, and the ventilation mode is turned on by the control box 10 through the host computer 11. At this time, the content in the environment The air of the acidic corrosive gas enters from the fan 1, and enters the acidic corrosive gas filter system 3 through the air intake electric three-way valve 2, where it is purified by adsorption and filtration of the cylindrical adsorption filter 18, and the purified air passes through the air supply electric three-way The valve 4 enters the air conditioner indoor unit 6, where it is regulated by the cooling / heat supplied by the outdoor unit 5, and enters the enclosed space 13 after reaching the set temperature and humidity; in the enclosed space 13, the ov...

Embodiment 2

[0053] Embodiment 2 clean air supply mode

[0054] Cleaning and ventilation means that when the environment of the confined space 13 has neither acidic corrosive gas nor other pollutants, and overpressure ventilation is required, commands are issued from the hand panel 19 or touch screen 20 of the control center 12, and the control box 10 is controlled by the host computer 11. When this ventilation mode is turned on, the air in the environment enters from the fan 1, passes through the air-intake electric three-way valve 2, passes through the air-supply electric three-way valve 4, and enters the air-conditioning indoor unit 6 without passing through the acid corrosion gas filter system 3. , where the cold / heat supplied by the outdoor unit 5 is regulated, and enters the enclosed space 13 after reaching the set temperature and humidity; in the enclosed space 13, the overpressure signal is sent by the overpressure sensor 9 through the control box 10 and the host computer 11 After ...

Embodiment 3

[0056] Embodiment 3 isolates self-oxygenation mode

[0057] Isolation and ventilation is a kind of confined space protection work in the closed space 13 when the filter corrosion gas ventilation and / or clean ventilation are ineffective; Box 10 turns on this kind of ventilation mode, and the air intake three-way valve 2, the air supply three-way valve 4, the air discharge valve 7 and the air intake fan are all in the closed state, and the airtight space neither enters nor exhausts air; at this time , the wind in the closed space 13 can only enter the air-conditioning indoor unit 6, where the cooling / heat supplied by the outdoor unit 5 is regulated, and enters the closed space 13 after reaching the set temperature and humidity.

[0058] When performing isolation and ventilation, the self-oxygenation system 21 in the confined space 13 needs to be turned on so that the confined space 13 can form an overpressure. The maintenance time in the acidic corrosive gas environment should n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com