N type longitudinal silicon carbide MOS (metal oxide semiconductor) tube with high breakdown voltage

A high breakdown voltage, semiconductor tube technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of small breakdown voltage, strong electric field, device breakdown, etc., to increase the breakdown voltage and prevent local breakdown , Improve the effect of breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

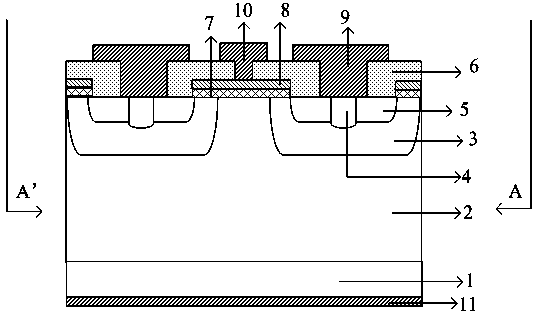

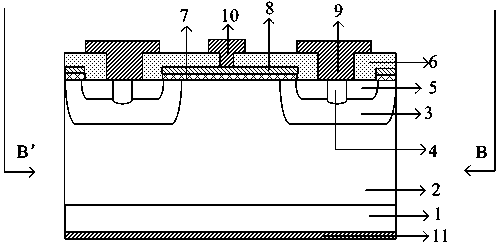

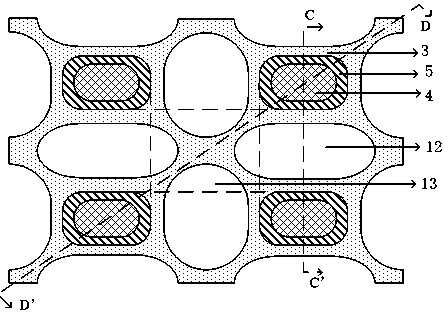

[0020] Combine below Figure 4 , Figure 5 and Figure 6 To describe the present invention in detail, a high breakdown voltage N-type vertical silicon carbide metal oxide semiconductor transistor includes: an N-type substrate 1, a drain metal 11 is connected to one side of the N-type substrate 1, and a drain metal 11 is connected to the N-type substrate 1. The other side of the type substrate 1 is provided with an N-type drift region 2, which is characterized in that a P-type base layer 3 is arranged on the N-type drift region 2, and a N-type base layer 3 distributed in an array is arranged on the P-type base layer 3. Type source region 5 and P type body contact region 4, be provided with N type drift region projection 12 formed by N type drift region 2 between every pair of adjacent N type source region 5, the boundary of N type drift region projection 12 Extending into the corresponding breakdown voltage enhancement region 13, the breakdown voltage enhancement region 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com