Golden low-emissivity coated glass and manufacturing method thereof

A technology of low-emission coating and manufacturing method, applied in chemical instruments and methods, glass/slag layered products, metal layered products, etc. , The product cannot obtain golden appearance and other problems, to achieve excellent shading performance, pure appearance and color, and good energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

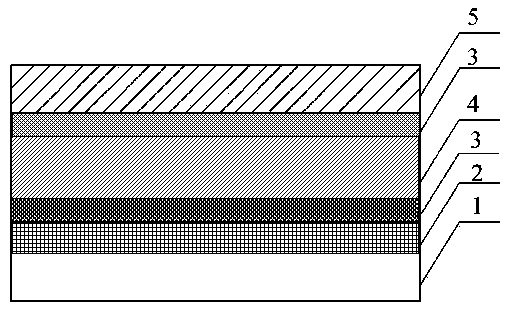

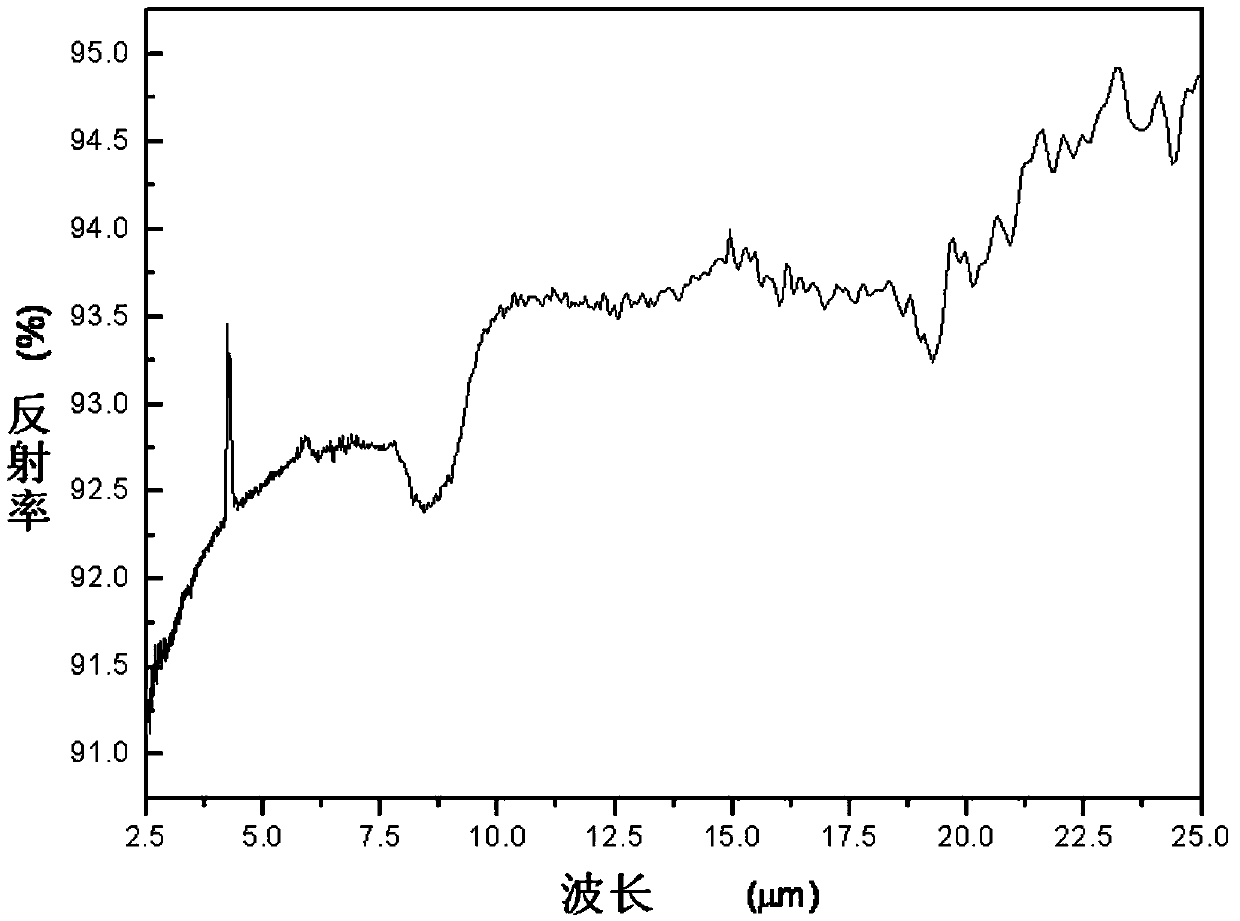

[0044] A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 21nm, the thickness of the nickel-chromium alloy induction layer is 3nm, the thickness of the gold functional layer is 40nm, the second nickel-chromium alloy induction layer The thickness of the ZnO:Al protective layer is 3nm, the thickness of the ZnO:Al protective layer is 12nm, and the glass substrate adopts float glass.

[0045] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0046] Step 1: Substrate pretreatment, us...

Embodiment 2

[0064] A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 22nm, the thickness of the nickel-chromium alloy induction layer is 3.5nm, the thickness of the gold functional layer is 45nm, and the thickness of the second nickel-chromium alloy induction layer is 45nm. The thickness of the layer is 3.5nm, the thickness of the ZnO:Al protective layer is 13nm, and the glass substrate adopts float glass.

[0065] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0066] Step 1: Substrate ...

Embodiment 3

[0084]A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 23nm, the thickness of the nickel-chromium alloy induction layer is 4nm, the thickness of the gold functional layer is 42nm, the second nickel-chromium alloy induction layer The thickness of the ZnO:Al protective layer is 4nm, the thickness of the ZnO:Al protective layer is 14nm, and the glass substrate adopts float glass.

[0085] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0086] Step 1: Substrate pretreatment, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com