Low-temperature electric melting formula for transparent glass, process method thereof and transparent glass prepared through low-temperature electric melting formula and process method

A bright material and electric fusion technology, applied in the field of glass craft products production, can solve the problems of unseen technology research and development and reports, consider the problem of low temperature furnace electric melting, etc., achieve high purity and brightness, improve the operating environment of workers, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

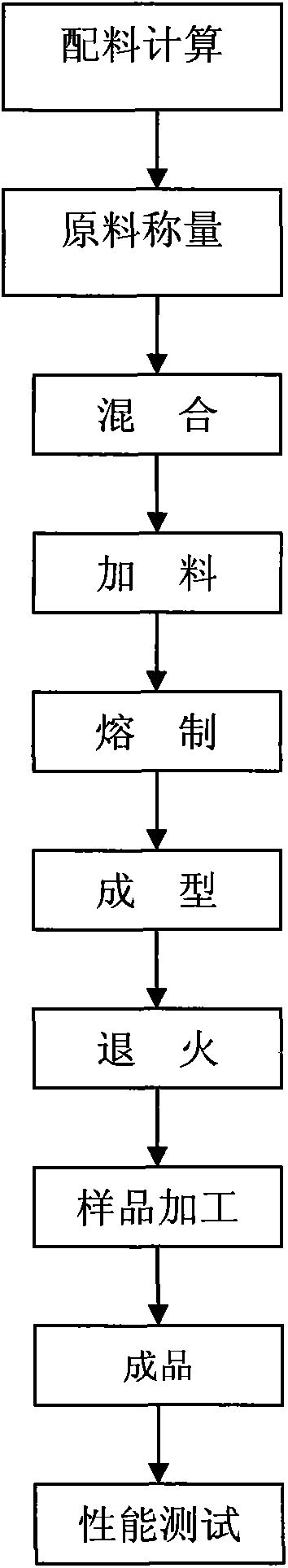

Method used

Image

Examples

Embodiment 1

[0056] The formula of each raw material is shown in Table 2, the chemical composition of each raw material is shown in Table 3, and the calculated chemical composition of the glass is shown in Table 4.

[0057] The raw material formula (kg) of table 2, embodiment 1

[0058]

[0059] *Decolorizer: Er 2 o 3 40g, Nd 2 o 3 60g

[0060] Table 3, various raw material mass percentage composition (%)

[0061] main ingredient

SiO 2

B 2 o 3

Al 2 o 3

Fe 2 o 3

CaO

ZnO

BaO

K 2 o

Na 2 o

Li 2 o

Silica powder

99.1

0.01

0.02

0.02

55.18

35.40

15.76

Al(OH) 3

64.73

0.01

0.02

54.82

...

Embodiment 2

[0083] The raw material formula of embodiment 2 is shown in Table 5, and the chemical composition of the bright material glass calculated therefrom is shown in Table 6.

[0084] The raw material formula (kg) of table 5 embodiment 2

[0085] raw material

Silica powder

Al(OH) 3

ZnO

Soda ash

barium carbonate

lithium carbonate

Sb 2 o 3

62.76

2.5

4.56

2.78

9.84

2.2

23.81

7.15

4.86

1.25

2.5

0.5

0.5

[0086] *Decolorizer: Er 2 o 3 40g, Nd 2 o 3 60g

[0087] The glass composition table (mass percentage) of table 6 embodiment 2

[0088] Composition SiO 2 B 2 o 3 Al 2 o 3

Fe 2 o 3 CaO

ZnO

K 2 o

Na 2 o

BaOLi 2 OSb 2 o 3

Composition 62.193.41.8

0.0155.4

2.18

4.8

15.0

4.50.20.5

[0089] *The...

Embodiment 3

[0106] The raw material formulation of embodiment 3 is shown in Table 7, and the chemical composition of raw materials is shown in Table 3, and the transparency calculated therefrom

[0107] The chemical composition of the glass is shown in Table 8.

[0108] The raw material formula (kg) of table 7, embodiment 3

[0109] raw material

Silica powder

boric acid

Al(OH) 3

ZnO

Soda ash

potassium carbonate

barium carbonate

lithium carbonate

Sb 2 o 3

60.75

2.5

6.0

2.78

10.92

2.52

23.11

7.45

5.51

1.25

2.5

0.5

0.5

[0110] *Decolorizer: K 2 MnO 4 40g, Nd 2 o 3 60g

[0111] The glass composition table (mass percentage) of table 8 embodiment 2

[0112] Composition SiO 2 B 2 o 3 Al 2 o 3 Fe 2 o 3

CaO 2 ONa 2 OBaOLi 2 OSb 2 o 3

Composition 60.24.21.80.015

62.55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com