Dual-cured high-performance LED packaging material and preparation method thereof

A technology of LED encapsulation and dual curing, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems such as the decrease of optical properties such as the refractive index and light transmittance of the material, and the uneven mixing of the material matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

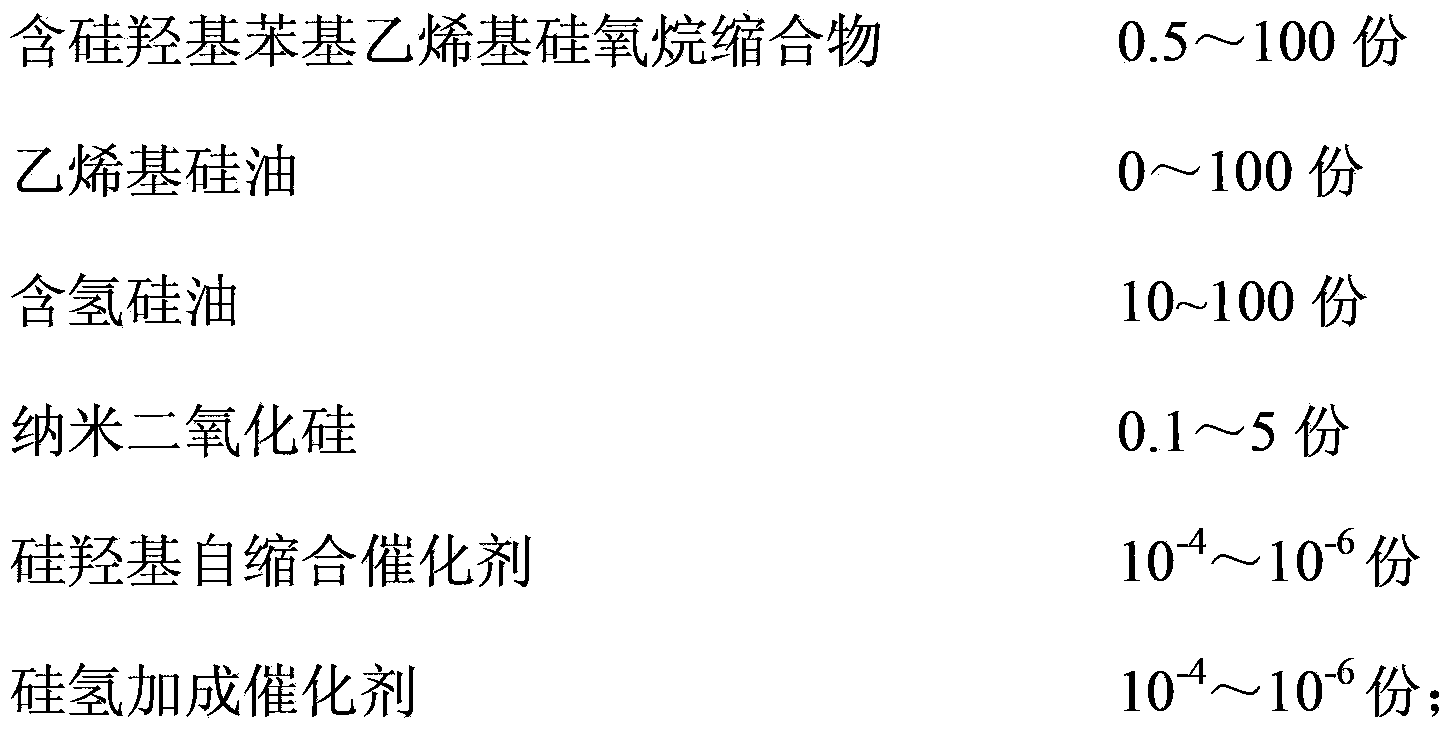

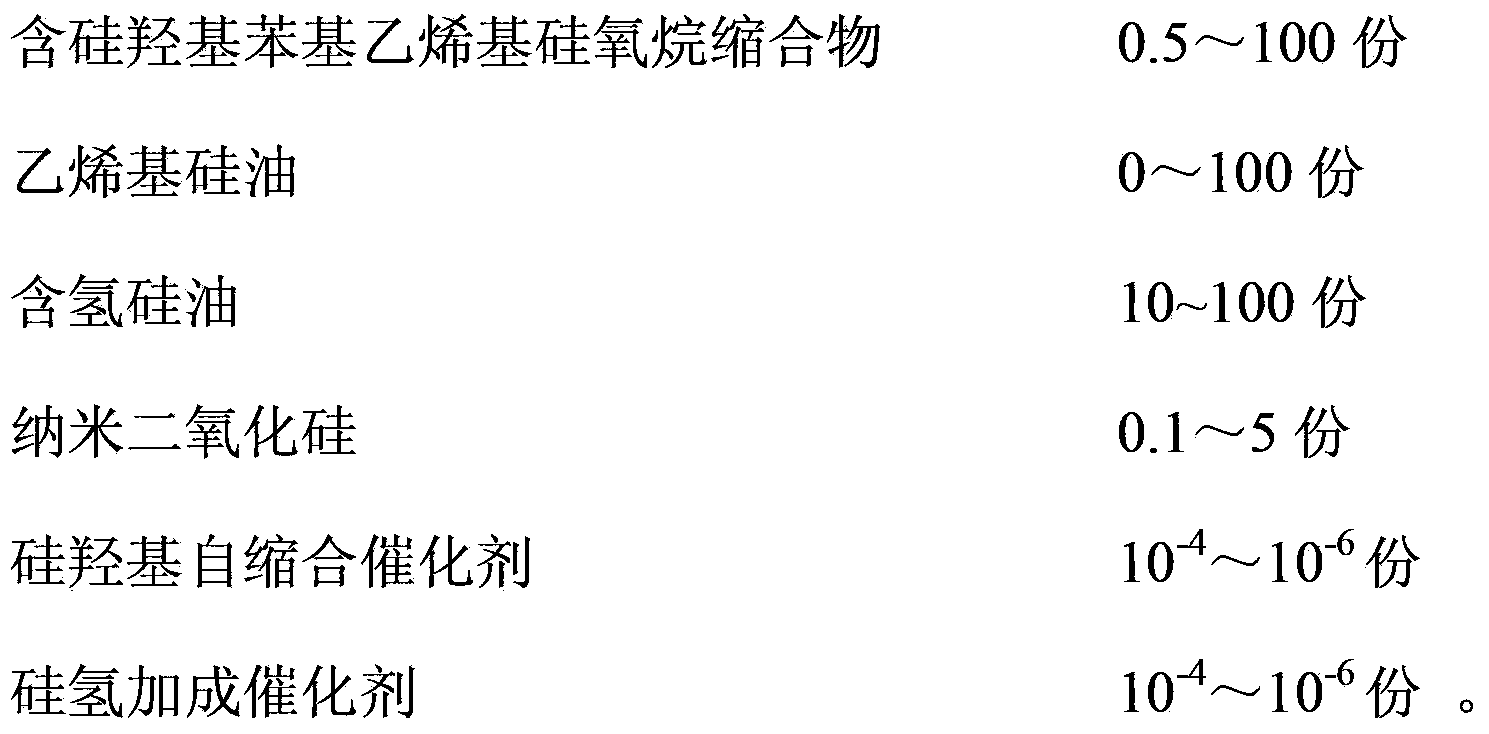

Method used

Image

Examples

Embodiment 1

[0024] 1. 20 parts by mass of phenyltrimethoxysilane, 20 parts by mass of vinyltrimethoxysilane, 80 parts by mass of dimethyldimethoxysilane, catalyst hydrochloric acid 1×10 -2 Parts by mass, 0.1 part by mass of water, 500 parts by mass of ethanol, hydrolyzed at 65°C for 5 hours, and removed water and organic solvents to obtain a condensate of silicon-hydroxyl-containing phenylvinylsiloxane (vinyl content: 3%).

[0025] 2. 99 parts by mass of vinyl silicone oil (vinyl content 0.84%, Guangzhou Hongyu Organic Silicon Material Co., Ltd.), 1 part by mass of silicon-containing hydroxyphenyl vinyl siloxane condensate synthesized in step 1, 75 parts by mass of hydrogen-containing silicone oil parts (hydrogen content 0.5%, Kaihua County Taicheng Silicone Co., Ltd.), 2.5 parts by mass of 20-40nm silicon dioxide, hydroxyl self-condensation catalyst dibutyltin diacetate 1×10 -4 Parts by mass, hydrosilylation catalyst H 2 PtCl 6 Isopropanol solution 3 x 10 -6 parts by mass, mixed evenl...

Embodiment 2

[0029] 1. 80 parts by mass of diphenyldimethoxysilane, 5 parts by mass of methylvinyldimethoxysilane, 20 parts by mass of dimethyldimethoxysilane, catalyst hydrochloric acid 16×10 -3 Parts by mass, 1 part by mass of water, 400 parts by mass of tetrahydrofuran, hydrolyzed at 60°C for 10 hours, and removed water and organic solvents to obtain a silicon hydroxyphenyl vinylsiloxane condensate (vinyl content 1%).

[0030] 2. 1 mass part of vinyl silicone oil (vinyl content 0.84%, Guangzhou Hongyu Organic Silicon Material Co., Ltd.), 99 mass parts of silicon-containing hydroxyphenyl vinyl siloxane condensate synthesized in step 1, 60 mass parts of hydrogen-containing silicone oil parts (hydrogen content 0.5%, Kaihua County Taicheng Silicone Co., Ltd.), 0.5 parts by mass of 100nm nano-silica, hydroxyl self-condensation catalyst dibutyltin dilaurate 6×10 -6 Parts by mass, hydrosilylation catalyst Pt (PPh 3 ) 4 2×10 -5 parts by mass, mixed uniformly, reacted at 95° C. for 0.35 h, th...

Embodiment 3

[0033] 1. 30 parts by mass of diphenyldiethoxysilane, 10 parts by mass of methylvinyldimethoxysilane, 80 parts by mass of dimethyldiethoxysilane, catalyst dibutyltin diacetate 5×10 -3Parts by mass, 0.5 parts by mass of water, 200 parts by mass of ethanol, hydrolyzed at 45°C for 18 hours, removed water and organic solvents, and obtained silicon hydroxyphenyl vinylsiloxane condensate (vinyl content 1.7%).

[0034] 2. 10 parts by mass of vinyl silicone oil (vinyl content 0.09%, Guangzhou Hongyu Organic Silicon Material Co., Ltd.), 90 parts by mass of silicon-containing hydroxyphenyl vinyl siloxane condensate synthesized in step 1, 100 parts by mass of hydrogen-containing silicone oil parts (hydrogen content 1.54%, Kaihua County Taicheng Organic Silicon Co., Ltd.), 40 ~ 70nm nano-silica 1 mass part, hydroxyl self-condensation catalyst stannous octoate 3.5 × 10 -5 Parts by mass, hydrosilylation catalyst H 2 PtCl 6 A solution of isopropanol 2.9 x 10 -6 parts by mass, mixed unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com