Conductive anticorrosive coating and preparation method thereof

An anti-corrosion coating and coating technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve problems such as large amount of fillers, resin incompatibility, strict substrate pre-treatment, etc., to improve temperature resistance Anti-combustion performance, improved corrosion resistance, and improved construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

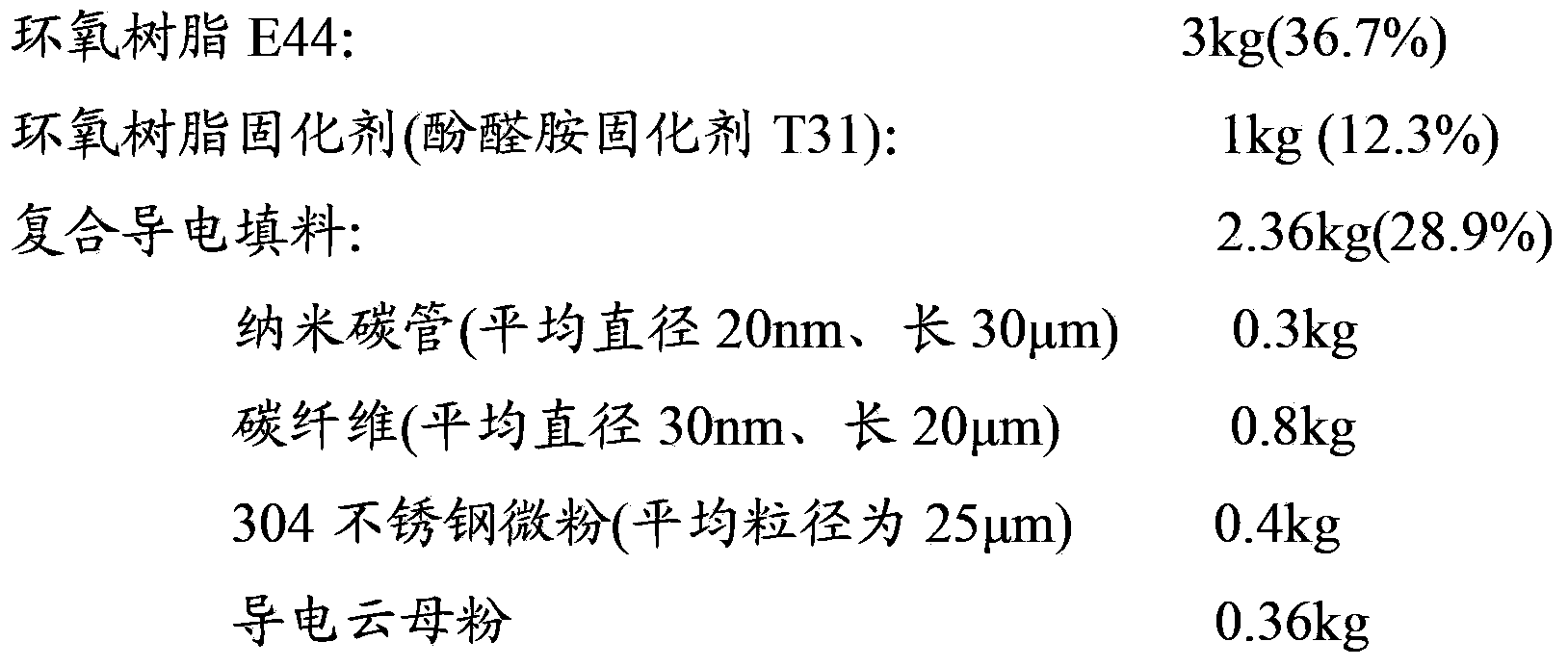

[0044] A kind of conductive, anti-corrosion paint, paint film former, pigment and filler and auxiliary agent comprise the following components:

[0045]

[0046]

[0047] The preparation method of the conductive, anti-corrosion coating of the present embodiment is as follows:

[0048] (1) Mix other paint film formers, pigments and fillers, auxiliary components and mixed solvents except epoxy resin curing agent, put them in a paint grinder, stir and grind at a speed of 1850rpm for 15 minutes, then use 200 mesh filter;

[0049] (2) Add epoxy resin curing agent, mix and stir evenly, and get ready.

[0050] The paint of this embodiment was sprayed or brushed onto the surface of the sandblasted carbon steel part by spraying or brushing, and after curing at room temperature for 24 hours, a conductive and anti-corrosion coating with a thickness of 180 μm was obtained.

[0051] The surface resistivity of the coating was 75 Ωcm. Coated Q235 steel was treated at 30°C, 5%NaOH, 5...

Embodiment 2

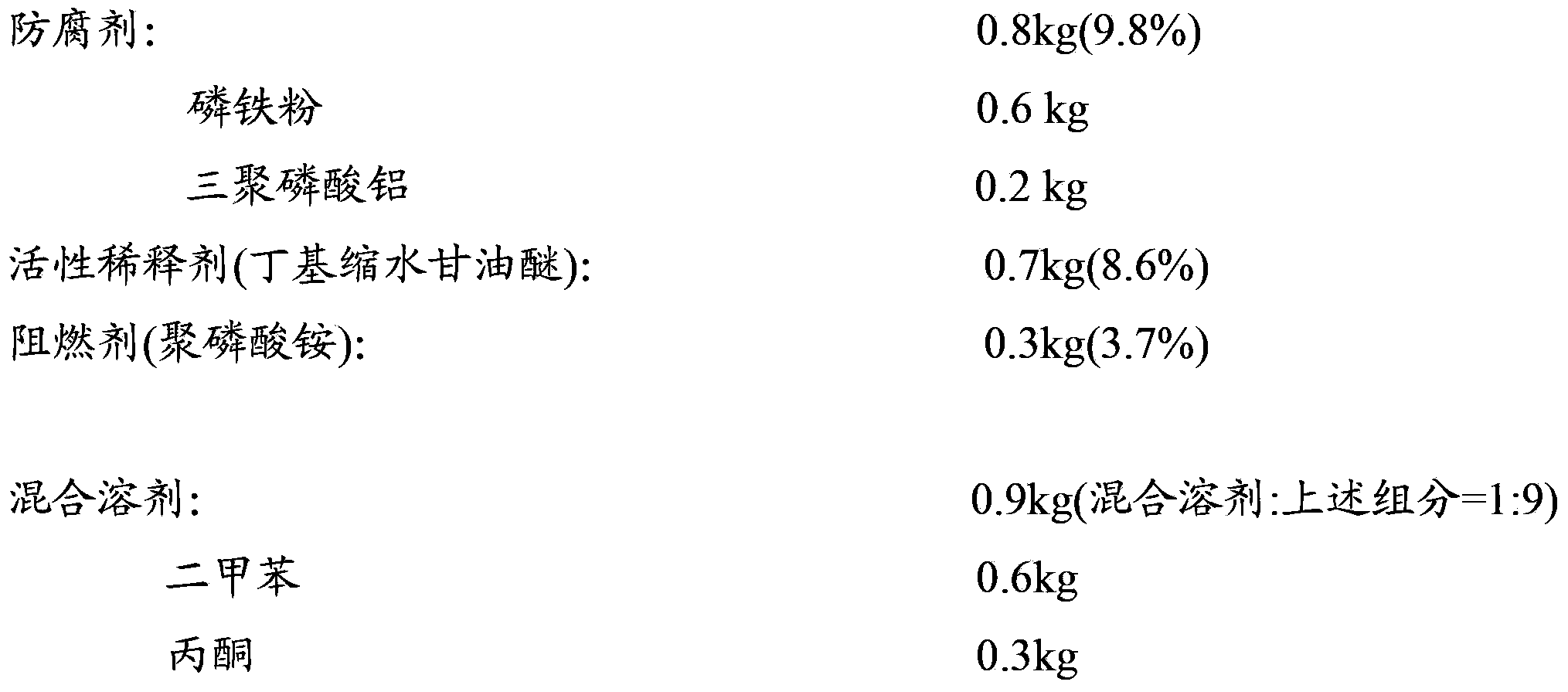

[0053] A kind of conductive, anti-corrosion paint, paint film former, pigment and filler and auxiliary agent comprise the following components:

[0054]

[0055]

[0056] The preparation method of the conductive, anti-corrosion coating of the present embodiment is as follows:

[0057] (1) Mix other paint film formers, pigments and fillers, auxiliary components and mixed solvents except epoxy resin curing agent, put them in a paint grinder, stir and grind at a speed of 2050rpm for 25 minutes, then use 200 mesh filter;

[0058] (2) Add epoxy resin curing agent, mix and stir evenly, and get ready.

[0059] Spray or brush the paint of this embodiment onto the surface of the sandblasted carbon steel part, and after curing at room temperature for 24 hours, a 200 μm thick conductive and anti-corrosion coating is obtained.

[0060] The surface resistivity of the coating was 80 Ωcm. Coated Q235 steel was treated at 30°C, 5%NaOH, 5%H 2 SO 4 After immersing in 3.5% NaCl solution...

Embodiment 3

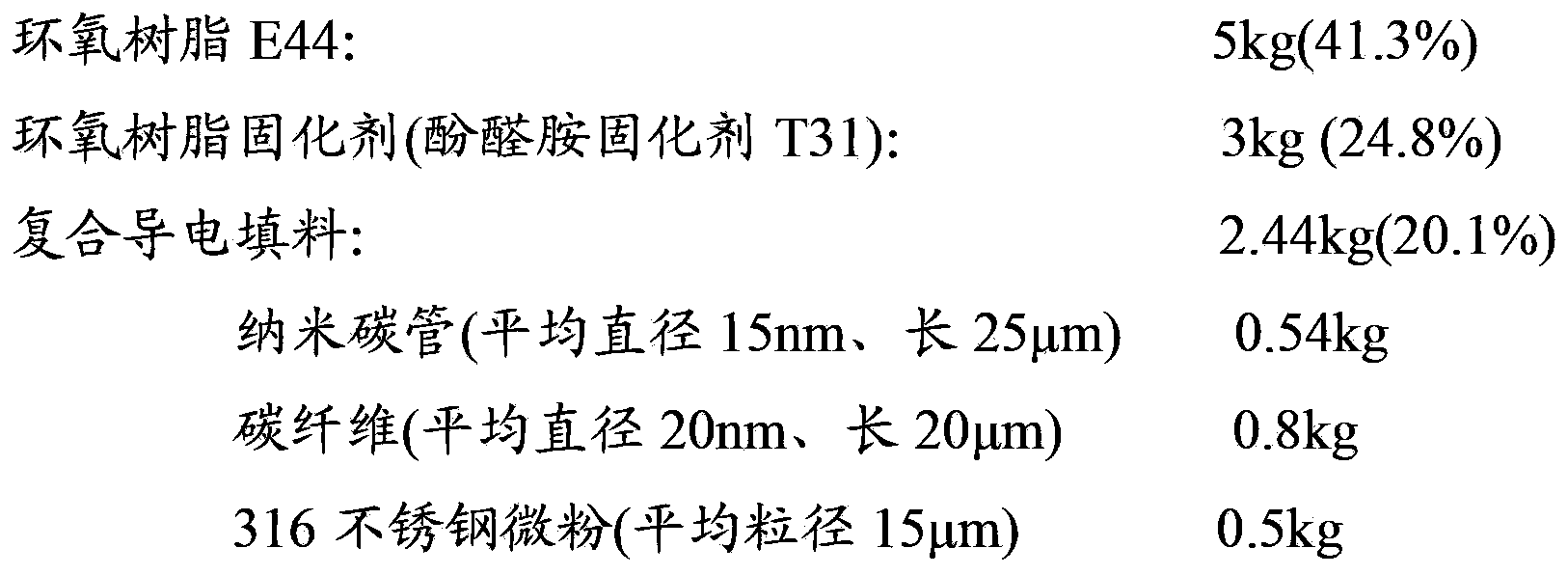

[0062] A kind of conductive, anti-corrosion paint, paint film former, pigment and filler and auxiliary agent comprise the following components:

[0063]

[0064]

[0065] The preparation method of the conductive, anti-corrosion coating of the present embodiment is as follows:

[0066] (1) Mix other coating film formers, pigments and fillers, auxiliary components and mixed solvents except epoxy resin curing agent, put them into a coating grinder, stir and grind at a speed of 1500rpm for 25 minutes, then use 200 mesh filter;

[0067] (2) Add epoxy resin curing agent, mix and stir evenly, and get ready.

[0068] The paint of this embodiment was sprayed or brushed on the surface of the sandblasted carbon steel parts by spraying or brushing, and after curing at room temperature for 24 hours, a conductive and anti-corrosion coating with a thickness of 250 μm was obtained.

[0069] The surface resistivity of the coating was 70 Ωcm. Coated Q235 steel was treated at 30°C, 5%Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com