A kind of polyurethane damping floor material and preparation method thereof

A floor material and polyurethane technology, applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve problems such as vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

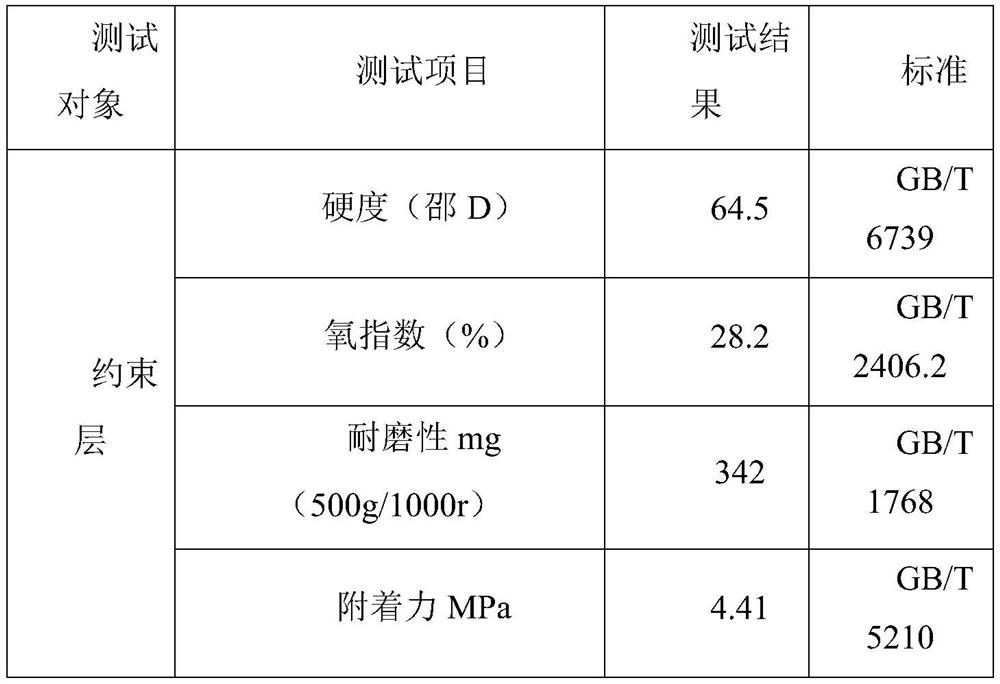

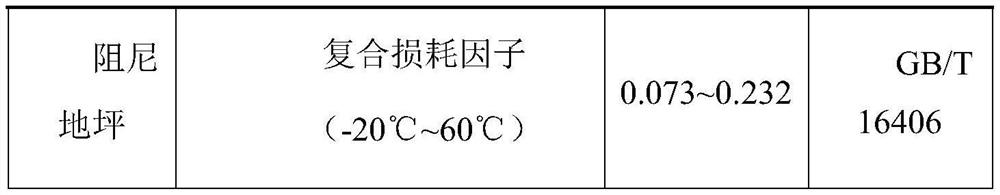

Embodiment 1

[0042] Polyether polyol Voranol TM 2000LM 500g was heated and dehydrated in a three-necked flask connected with a vacuum device and equipped with a stirrer and a thermometer for 2h, and then slowly added 125g of aromatic diisocyanate MDI-50 to react for 2-3h to prepare a prepolymer with an NCO% of 3.36%. That is, component A of the damping layer. Component B consists of 11 parts of chain extender tripropylene glycol (TPG), 32.9 parts of liquid flame retardant tris(2-chloropropyl) phosphate (TCPP), 55.7 parts of 100 mesh mica powder, and defoamer BYK-A530 0.2 parts, catalyst bismuth isooctanoate Bicat Zn 0.2 parts are mixed and stirred in a kneader. A and B components are mixed at a mass ratio of 3:2 (functional group equivalent ratio 1.05:1), stirred, and then scraped on the surface of the metal substrate with an anti-corrosion primer. The thickness of the scraped coating is about 1mm. A damping layer is obtained after curing.

[0043]Stir and mix HDI trimer N3300 and N380...

Embodiment 2

[0050] Polyether polyol Voranol TM 1000LM 500g was heated and dehydrated in a three-neck flask connected with a vacuum device and equipped with a stirrer and a thermometer for 2h, then slowly added 250g of aromatic diisocyanate MDI-50 to react for 2-3h to prepare a prepolymer with an NCO% of 5.6%. That is, component A of the damping layer. Component B consists of 13.95 parts of chain extender 2-ethyl-1.3-hexanediol (EHD), 35 parts of liquid flame retardant tris(2-chloropropyl) phosphate (TCPP), 50.55 parts of 400 mesh mica powder, 0.25 parts of defoamer BYK-A530 and 0.25 parts of catalyst Bicat Zn are mixed and stirred in a kneader. A and B components are mixed at a mass ratio of 3:2 (functional group equivalent ratio 1.05:1), stirred, and scraped on the surface of the metal substrate with an anti-corrosion primer. The thickness of the scraped coating is about 1mm. A damping layer is obtained after curing.

[0051] Stir and mix HDI trimer N3300 and N3800 in a reactor at a ...

Embodiment 3

[0059] Polyether polyol Voranol TM 1000LM 500g was heated and dehydrated in a three-necked flask connected with a vacuum device and equipped with a stirrer and a thermometer for 2 hours, then slowly added 174g of aromatic diisocyanate TDI-80 / 20 to react for 2-3 hours to prepare a prepolymer with an NCO% of 6.2%. The body is the A component of the damping layer. Component B consists of 18.2 parts of chain extender DPG, 35 parts of liquid flame retardant tris(2-chloropropyl) phosphate (TCPP), 46 parts of 400 mesh mica powder, 0.4 parts of defoamer BYK-A530, catalyst isooctanoic acid Bicat Zn 0.4 parts are mixed and stirred in a kneader. A and B components are mixed at a mass ratio of 2:1 (functional group equivalent ratio 1.05:1), stirred, and then scraped on the surface of the metal substrate with an anti-corrosion primer. The thickness of the scraped coating is about 1mm. A damping layer is obtained after curing.

[0060] Stir and mix HDI trimer N3300 and N3800 in a reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com