Molded normal temperature curing urethane resin composition and preparation method thereof

A polyurethane resin, room temperature curing technology, applied in the field of chemical materials and its preparation, can solve the problems of adverse effects of curing process, inability to use in low temperature areas, poor aging performance and low temperature performance of polyurethane resin, etc., and achieves good construction process performance and preparation method. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of pouring type normal temperature curing polyurethane resin composition comprises the following steps:

[0031] (1) Put the polymer polyol into the reactor, stir, vacuum dehydrate after heating up, add isocyanate after cooling down, and after heating up to react, prepare a prepolymer terminated with isocyanate, cool down for later use;

[0032] The polymer polyol is hydroxyl-terminated polybutadiene, or a mixture of hydroxyl-terminated polybutadiene and polytetrahydrofuran polyol, or a mixture of hydroxyl-terminated polybutadiene and polytetrahydrofuran-oxypropylene copolyether polyol; preferably hydroxyl-terminated Mixture of polybutadiene and polytetrahydrofuran-propylene oxide copolyether polyol;

[0033] The isocyanate is a mixture of one or more of toluene diisocyanate, isophorone diisocyanate, diphenylmethane diisocyanate and its derivatives, polymethylene phenyl polyisocyanate; preferably toluene diisocyanate, liquefied diphenyl Met...

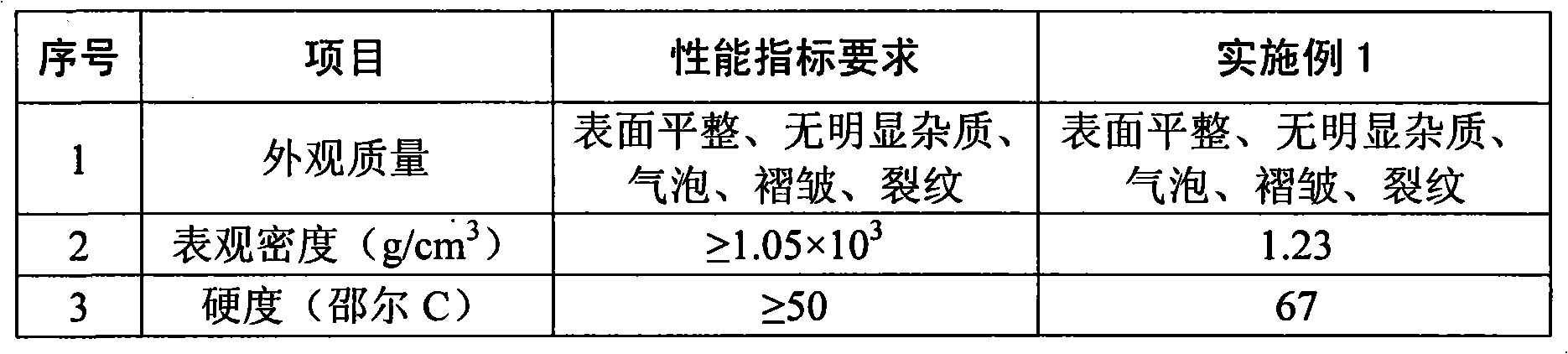

Embodiment 1

[0041] Put 300g of hydroxyl-terminated polybutadiene (hydroxyl value 45mgKOH / g) into a one-liter four-necked bottle, stir and heat up to 100-120°C, dehydrate at -0.1MPa for two hours, cool down to 50-60°C, add toluene diisocyanate (TDI 80) 30g, liquefy MDI 14g, then slowly raise the temperature to 90°C, keep warm, stir for two hours to prepare a prepolymer, cool down to below 50°C, and set aside.

[0042] Take 300g of prepolymer, add 150g of dibutyl phthalate, carbon black N55048g, silicon micropowder 180g, calcium sulfate whisker 20g, calcium oxide 4g, add coupling agent KH-56030g, defoamer BYK A-5306g, Wetting agent BYK-907510g, antioxidant H-2641.0g, ultraviolet light absorber UV-5310.8g, stir well and discharge, packaged as Class A substances.

[0043] Dilute E-300 with dibutyl phthalate to a 50% solution, packaged as a category B substance.

[0044] Take 300g of the above-mentioned A-type substance and 16.6g of B-type substance, fully stir at room temperature, mix evenly...

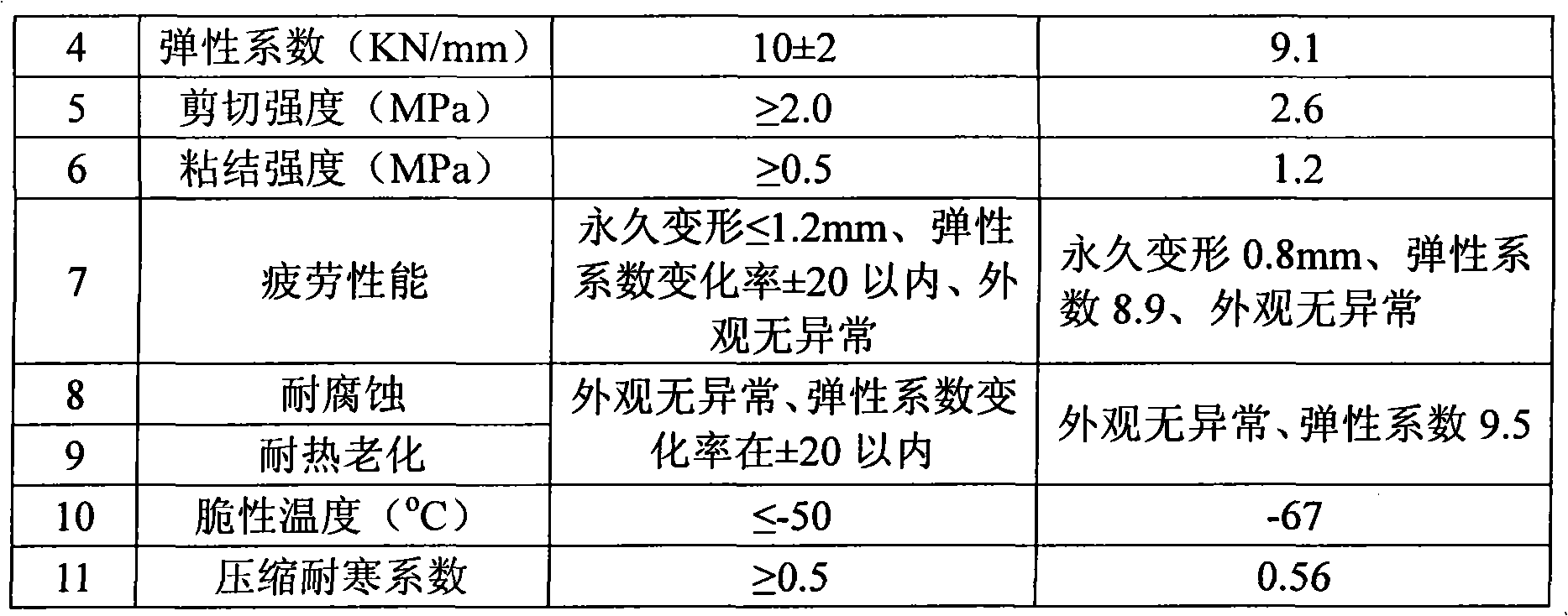

Embodiment 2

[0053] Put 210g of hydroxyl-terminated polybutadiene (hydroxyl value 45mgKOH / g) and 90g of polytetrahydrofuran ether glycol (hydroxyl value 112mgKOH / g) into a one-liter four-necked bottle, stir and heat up to 100-120°C, and dehydrate at -0.1MPa After two hours, cool down to 50-60°C, add 57g of toluene diisocyanate (TDI 80), then slowly raise the temperature to 90°C, keep warm, stir for two hours, cool down to below 50°C, and prepare a prepolymer for later use.

[0054] Take 300g of prepolymer, add 108g of dibutyl phthalate, 1.0g of carbon black N550, 200g of silicon micropowder, 20g of calcium sulfate powder, 10g of calcium oxide, add 1.0g of coupling agent KH-560, defoamer BYK A- 5301.0g, wetting agent BYK-90751.0g, antioxidant H-26410g, ultraviolet light absorber UV-53115g, stir well and discharge, packaged as Class A substances.

[0055] Dilute E-300 with dibutyl phthalate to a 50% solution, packaged as a category B substance.

[0056] Take 300g of the above-mentioned A-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com