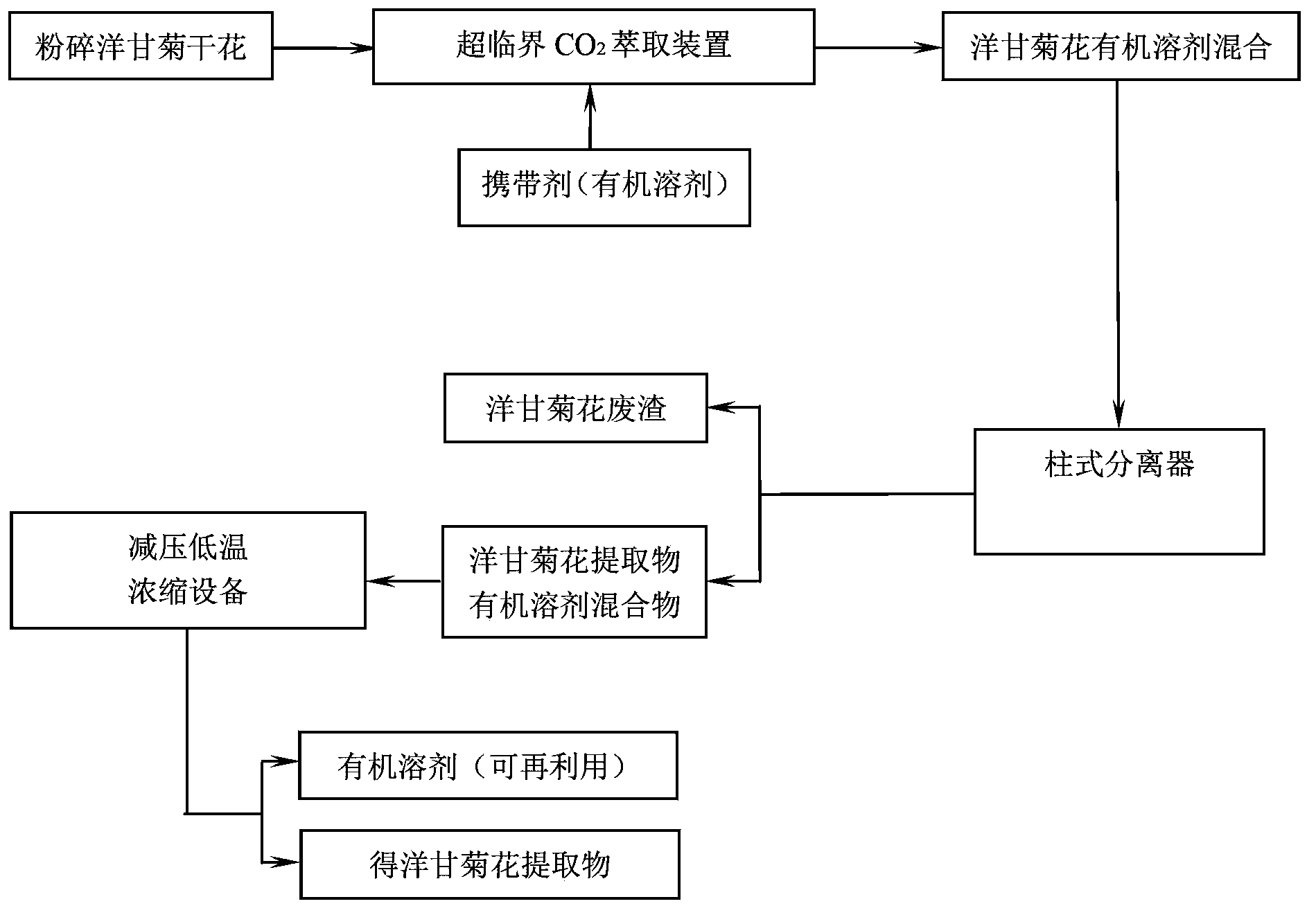

Method used for extracting chamomille extract by supercritical carbon dioxide extraction

A chamomile extract, carbon dioxide technology, applied in cosmetics, drug combinations, pharmaceutical formulations, etc., can solve the problems of low extraction rate of active ingredients, adverse effects on users, etc., and achieve short extraction time, highlight technological progress and strong selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 10kg of dried chamomile flowers with a water content of ≤20%, crush them through a 40-mesh sieve, and place them in supercritical CO 2 In the extraction kettle, feed carbon dioxide at a flow rate of 50L / h, and at the same time use an auxiliary pump to inject 95% ethanol as a carrier agent at a rate of 1L / h, extract for 2.5 hours at 50°C and a pressure of 15MPa, and put the extract into a column separation kettle Separation to obtain the residual water chamomile extract, and then place the extract in a vacuum low-temperature concentration equipment, reduce the pressure to -0.098MPa, and remove the residual water at 50°C to obtain 0.26kg of chamomile extract. The yield is 2.6%.

Embodiment 2

[0017] Take 10kg of dried chamomile flowers with a water content of ≤20%, crush them through a 60-mesh sieve, and place them in supercritical CO 2 In the extraction kettle, feed carbon dioxide at a flow rate of 55L / h, and at the same time use an auxiliary pump to inject 95% ethanol as a carrier agent at a rate of 1L / h, extract for 2 hours at 50°C and a pressure of 16MPa, and put the extract into a column separation kettle for separation , to obtain a chamomile ethanol residual water mixture, and then place the mixture in a reduced-pressure low-temperature concentration device, reduce the pressure to -0.08MPa, and recycle the organic solvent to remove the residual water at 45°C to obtain 0.28kg of chamomile extract. The rate was 2.8%.

[0018] The HL-2X25L / 40MPa-IIA supercritical CO used in this method 2 The extraction kettle and column separation kettle are produced by Hangzhou Huali Pump Industry Co., Ltd.; the R501 decompression and low temperature concentration equipment i...

example 1

[0021] Addition of chamomile handmade soap:

[0022] In the production of handmade soap, after the saponification reaction process is completed, 2.5% (kg / kg) of rose extract is added to the saponification solution when the temperature of the saponification solution is kept at 60°C, stirred evenly at a constant temperature, injected into the molding mold, cooled, divided, and packaged to obtain chamomile handmade soap. The chamomile extract is used in the production of handmade soaps, replacing the use of chemical essences and pigments in ordinary soaps. After use, the body surface can retain fragrance continuously, and can play the role of whitening, moisturizing, moisturizing, antibacterial, and anti-allergic. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com