Mnal alloy magnetic wave-absorbing material and preparation method thereof

A magnetic wave-absorbing and alloy technology, which is applied in the field of MnAl alloy magnetic wave-absorbing materials and its preparation, can solve the problems of high density, poor temperature stability, and easy corrosion of magnetic wave-absorbing materials, and achieve wide absorption frequency band and good temperature stability , Good anti-oxidation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

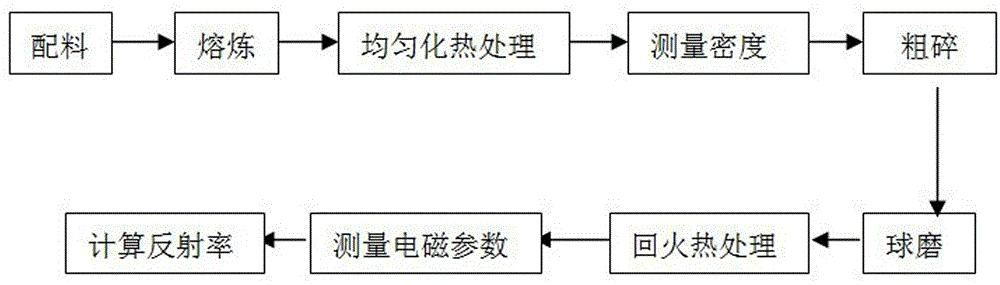

Method used

Image

Examples

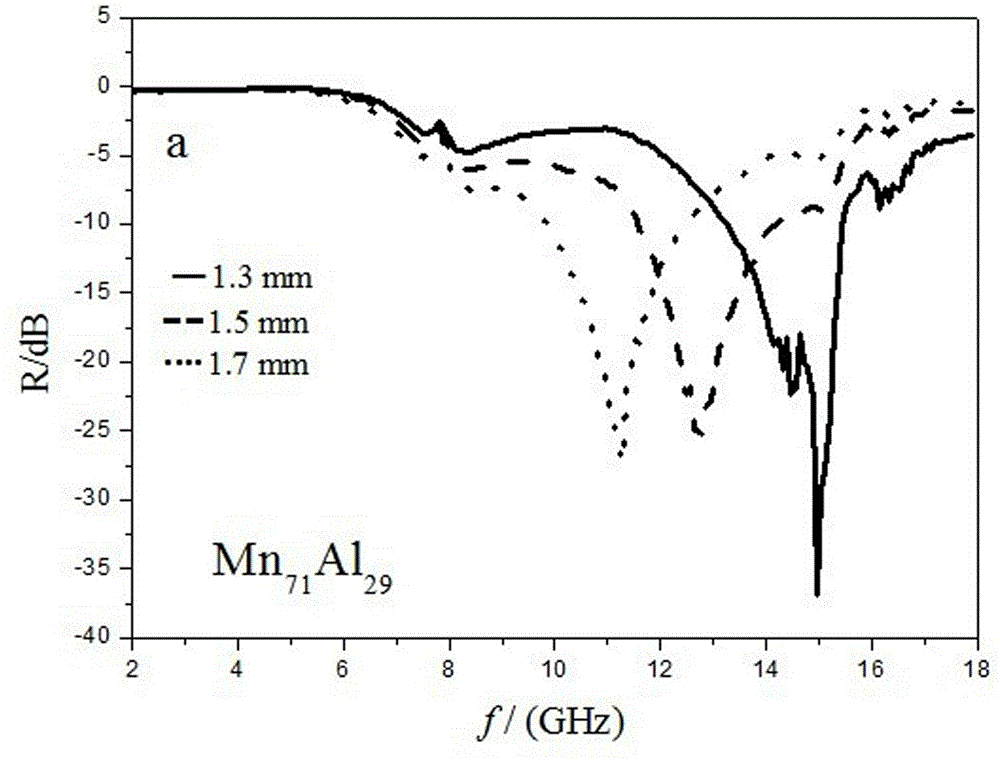

Embodiment 1

[0030] 1. Formulation: Mn 71 Al 29 (atomic percent).

[0031] 2. Specific implementation steps:

[0032] 1) Mn and Al metals with a purity ≥ 99.50% are used as Mn 71 Al 29 The stoichiometric ratio of the molecular formula is used as the benchmark, and 5% (atomic fraction) of Mn and 12% (atomic fraction) of Al are added to the ingredients;

[0033] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting 4 times;

[0034] 3) Keep the smelted ingot under the protection of argon at 1000°C for 48 hours and then water quench;

[0035] 4) Measure material density;

[0036] 5) Break the obtained alloy ingot into coarse powder with a particle size of less than 0.5mm, then put the zirconia ball and coarse powder into the zirconia tank at a mass ratio of 15:1, add ethanol as a protective agent, and use QM-lSP The planetary ball mill mills the alloy coarse powder fo...

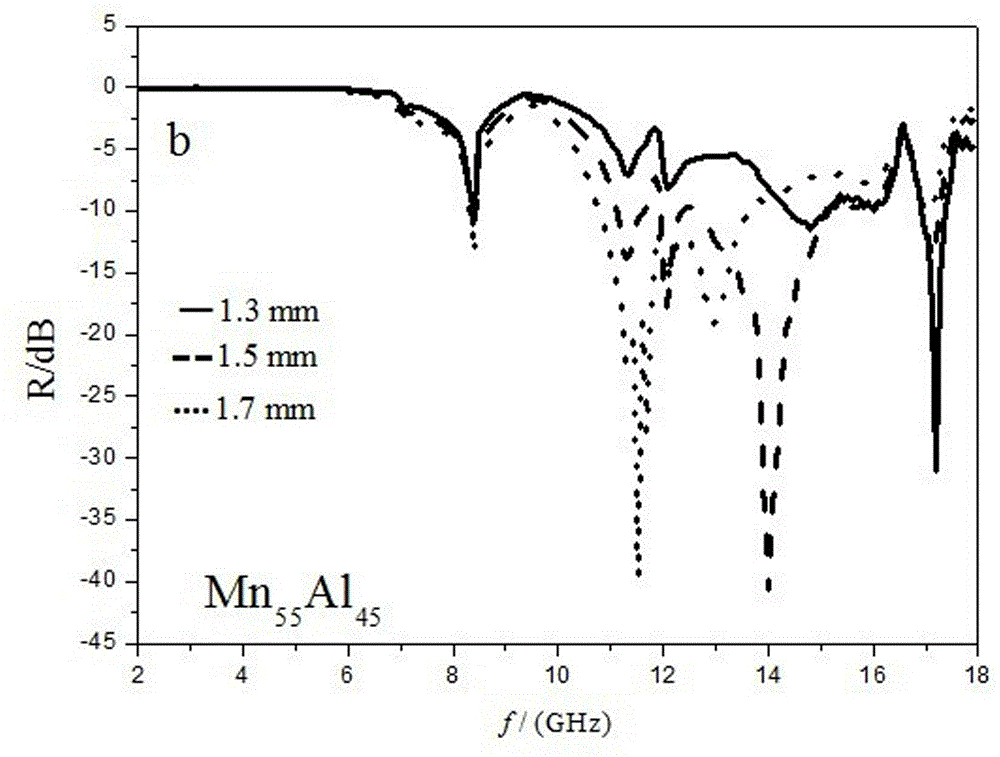

Embodiment 2

[0044] 1. Formulation: Mn 55 Al 45 (atomic percent).

[0045] 2. Specific implementation steps:

[0046] 1) Mn and Al metals with a purity ≥ 99.50% are used as Mn 55 Al 45 The stoichiometric ratio of the molecular formula is used as the benchmark, and 5% (atomic fraction) of Mn and 12% (atomic fraction) of Al are added to the ingredients;

[0047] 2) Melting in an electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, the melting is repeated 4 times;

[0048] 3) The smelted ingot is kept at 950°C for 70 hours under the protection of argon, and then water quenched;

[0049] 4) Measure material density;

[0050] 5) Break the obtained alloy ingot into coarse powder with a particle size of less than 0.5mm, then put the zirconia ball and coarse powder into the zirconia tank at a mass ratio of 12:1, add ethanol as a protective agent, and use QM-lSP The planetary ball mill milled the alloy coarse powder for 36 hours...

Embodiment 3

[0056] 1. Formulation: Mn 38 Al 62 (atomic percent).

[0057] 2. Specific implementation steps:

[0058] 1) Mn and Al metals with a purity ≥ 99.50% are used as Mn 38 Al 62 The stoichiometric ratio of the molecular formula is used as the benchmark, and 5% (atomic fraction) of Mn and 12% (atomic fraction) of Al are added to the ingredients;

[0059] 2) Melting in an electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, flipping and melting 4 times;

[0060] 3) Keep the smelted ingot at 1050°C for 36 hours under the protection of argon and then water quench;

[0061] 4) Measure material density;

[0062] 5) Break the obtained alloy ingot into a coarse powder with a particle size of less than 0.5mm, then put the zirconia ball and the coarse powder into a zirconia tank at a mass ratio of 19:1, add ethanol as a protective agent, and use QM-lSP The planetary ball mill milled the alloy coarse powder for 12 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com