Arrayed silver nanorods with surface-modifying gold nanoparticles and preparation method thereof

A technology of gold nanoparticles and silver nanorods, which is applied in the field of nanomaterials, can solve the problems of poor surface affinity and stability damage of silver, and achieve the effects of controllable shape, safe and convenient operation, and good assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

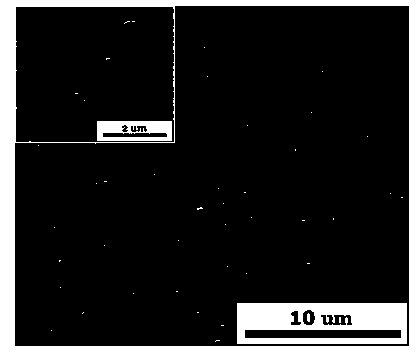

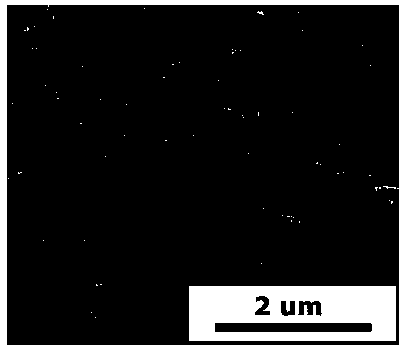

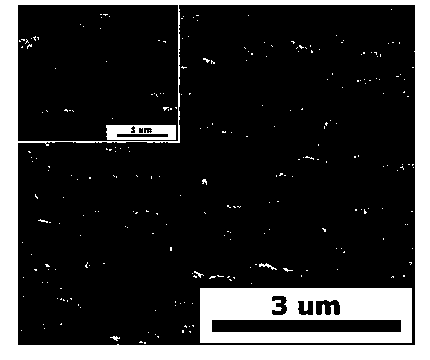

Image

Examples

Embodiment 1

[0041] The surface-modified gold nanoparticles of arrayed silver nanorods are prepared by the following steps:

[0042] (1) Prepare a citric acid aqueous solution with a concentration of 0.6M, immerse the glass slide deposited with silver nanorod arrays in the citric acid aqueous solution for 10 minutes, rinse with ultrapure water after taking it out, and dry it with nitrogen;

[0043] (2) Prepare a polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 0.5%, immerse the glass slide treated in step (1) in the polydiallyldimethylammonium chloride aqueous solution, soak After 30 min, the slides were taken out, rinsed with ultrapure water, dried with nitrogen, and sealed for storage;

[0044] (3) The gold colloid was prepared by reducing sodium citrate to chloroauric acid, and the prepared gold colloid was placed in a clean glass test tube, and the glass slides treated in step (2) were immersed in the gold colloid for the soaking time After 3 hours, w...

Embodiment 2

[0046] The surface-modified gold nanoparticles of arrayed silver nanorods are prepared by the following steps:

[0047] (1) Prepare a citric acid aqueous solution with a concentration of 0.6M, immerse the glass slide deposited with silver nanorod arrays in the citric acid aqueous solution for 10 minutes, rinse with ultrapure water after taking it out, and dry it with nitrogen;

[0048] (2) Prepare a polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 0.5%, immerse the glass slide treated in step (1) in the polydiallyldimethylammonium chloride aqueous solution, soak After 40 min, the slides were taken out, rinsed with ultrapure water, dried with nitrogen, and sealed for storage;

[0049] (3) The gold colloid was prepared by reducing sodium citrate to chloroauric acid, and the prepared gold colloid was placed in a clean glass test tube, and the glass slides treated in step (2) were immersed in the gold colloid for the soaking time After 5 hours, w...

Embodiment 3

[0051] The surface-modified gold nanoparticles of arrayed silver nanorods are prepared by the following steps:

[0052] (1) Prepare an aqueous acetic acid solution with a concentration of 0.4M, immerse the glass slide deposited with silver nanorod arrays in the aqueous acetic acid solution for 15 minutes, rinse with ultrapure water after taking it out, and dry it with nitrogen;

[0053] (2) Prepare a polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 0.8%, immerse the glass slide treated in step (1) in the polydiallyldimethylammonium chloride aqueous solution, soak After 30 min, the slides were taken out, rinsed with ultrapure water, dried with nitrogen, and sealed for storage;

[0054] (3) The gold colloid was prepared by reducing sodium citrate to chloroauric acid, and the prepared gold colloid was placed in a clean glass test tube, and the glass slides treated in step (2) were immersed in the gold colloid for the soaking time After 8 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com