Preparation method of Bi<3.64>Mo<0.36>O<6.55> nanometer particles and nanometer material made of Bi<3.64>Mo<0.36>O<6.55> nanometer particles

A nanoparticle and nanomaterial technology, which is applied in the preparation of Bi3.64Mo0.36O6.55 nanoparticle and its Bi3.64Mo0.36O6.55 nanomaterial, can solve the problem of less than 60% pass rate, pollution of rivers, lakes and seas, Dye wastewater treatment rate is less than 30% and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh an appropriate amount (0.00001~1mol) of bismuth salt and dissolve it in a certain amount (2~30ml) of water, and add a certain concentration (5~90%) of nitric acid solution under magnetic stirring conditions; add an appropriate amount (0.0001~2mol) of molybdic acid The salt solution is dissolved in the above solution, and the pH of the solution is adjusted with a certain concentration (1~27%) of ammonia water; then the mixed solution is poured into a crucible, and reacted by microwave. The resulting substance was washed several times with water and absolute ethanol successively, and then dried.

[0029] The molar ratio of bismuth salt and molybdate is (0.1~2):(0.5~8); microwave frequency: (20~230)W; microwave time: (0~60)min; pH=(1~14). The obtained particle size is in the size of 10-20nm Bi 3.64 Mo 0.36 o 6.55 Nano spherical particles.

Embodiment 2

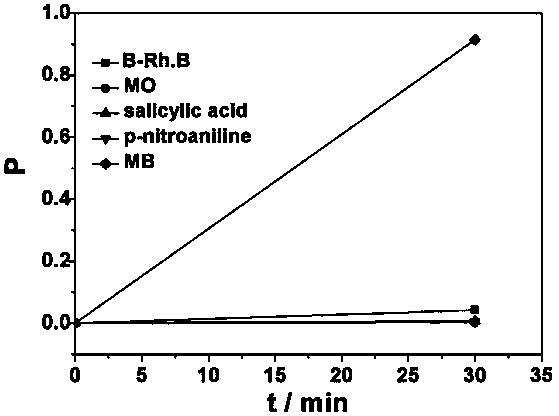

[0031] From figure 1 It can be seen that when S-2 is adsorbed for 30 minutes, the adsorption rate of MB is 91.6%. Under the same adsorption time, the adsorption rate of B-Rh.B is only about 4.3%. The adsorption rate of MO, salicylic acid and p-nitroaniline The adsorption rate is basically 0, indicating that Bi 3.64 Mo 0.36 o 6.55 It has high selective adsorption for methylene blue (MB).

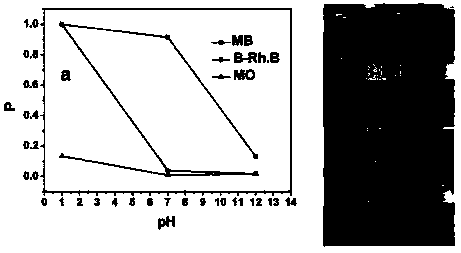

[0032] figure 2 It is the adsorption of different dyes by the S-2 sample under different pH conditions. From figure 2It can be seen from (a) that when S-2 is adsorbed at pH = 7 for 30 min, the adsorption rate of B-Rh.B is only 4.3%, and it basically does not adsorb MO. When S-2 was adsorbed at pH=12 for 30 min, neither B-Rh.B nor MO was adsorbed. However, when S-2 was adsorbed at pH=7 and 12 for 30 minutes, the adsorption rate P of MB could reach 91.6% and 13.2%, respectively. It shows that S-2 has a better adsorption capacity for MB than B-Rh.B and MO under neutral and alkaline con...

Embodiment 3

[0034] Table 1. Bi 3.64 Mo 0.36 o 6.55 The effect table of the adsorption amount of methylene blue on the sample at a certain moment at 25°C

[0035]

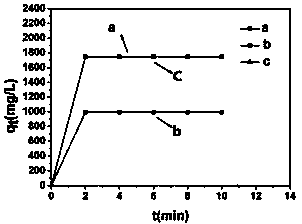

[0036] From Table 1 and image 3 It can be seen that the three products have extremely high adsorption effects on common dyes. The methylene blue is almost completely adsorbed within 2 minutes, and the equilibrium adsorption amount increases by less than 0.4mg / g from 2 minutes to 10 minutes. The adsorption capacities of S-3 and S-1 were almost the same, and the adsorption amount reached about 1746 mg / g within 2 min. The equilibrium adsorption capacity of S-2 reached 993.5 mg / g at 2 minutes, and the equilibrium adsorption capacity only increased by 0.5 mg / g from 2 minutes to 10 minutes, but the adsorption capacity of S-2 was smaller than that of S-1 and S-3 much.

[0037] Table 2. Three kinetic model parameters for the adsorption of methylene blue by S-1, S-2, and S-3 at 25 °C

[0038]

[0039] Figure 4 Three adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com