Solvothermal preparation method of bismuth trioxide microspheres and application thereof

A bismuth trioxide, solvothermal technology, applied in metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, bismuth compounds, etc., can solve the problem of high antibiotic content, antibiotic screening and production, strain breeding Technical difficulties, environmental pollution and other problems, to achieve the effect of high degradation efficiency, low cost and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

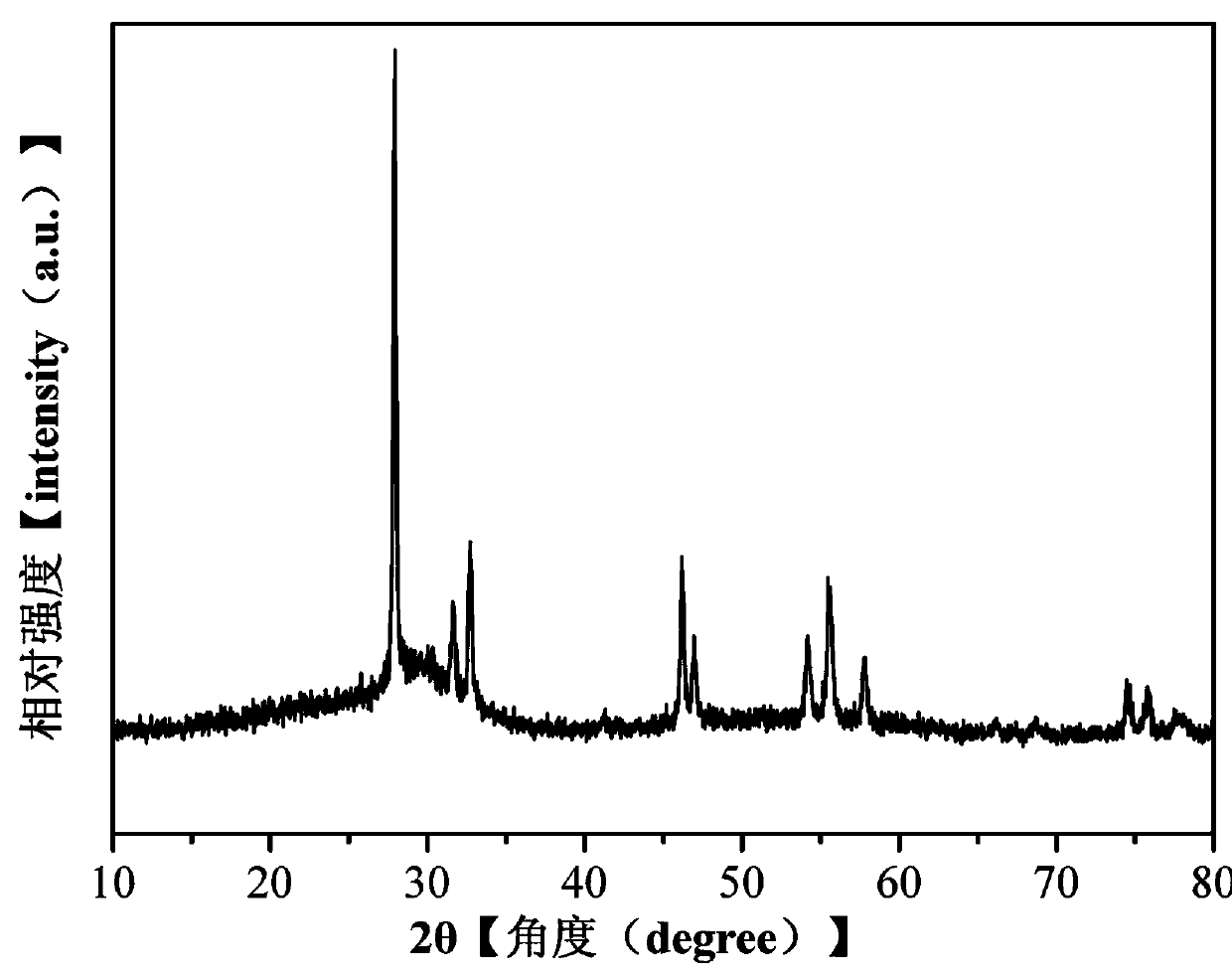

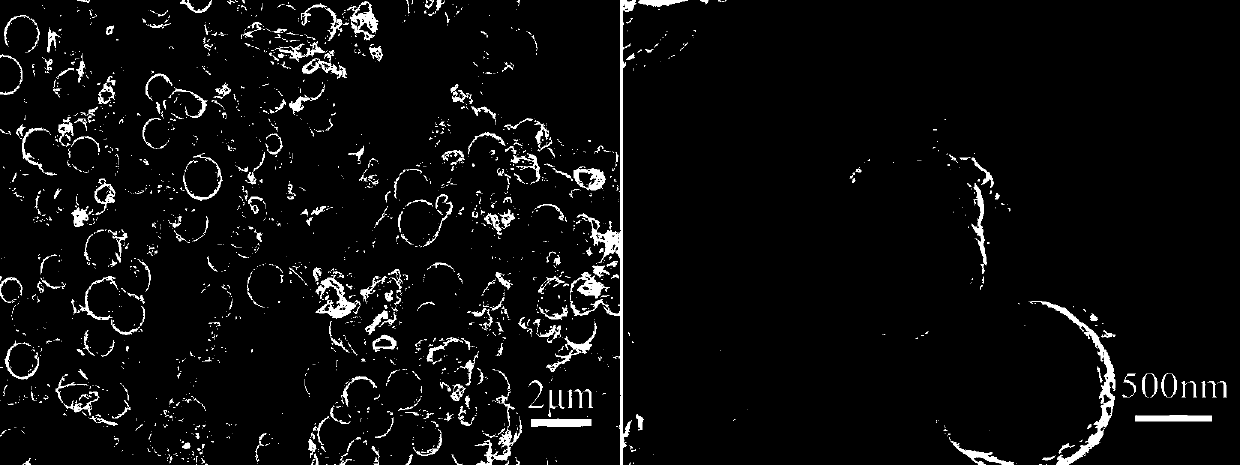

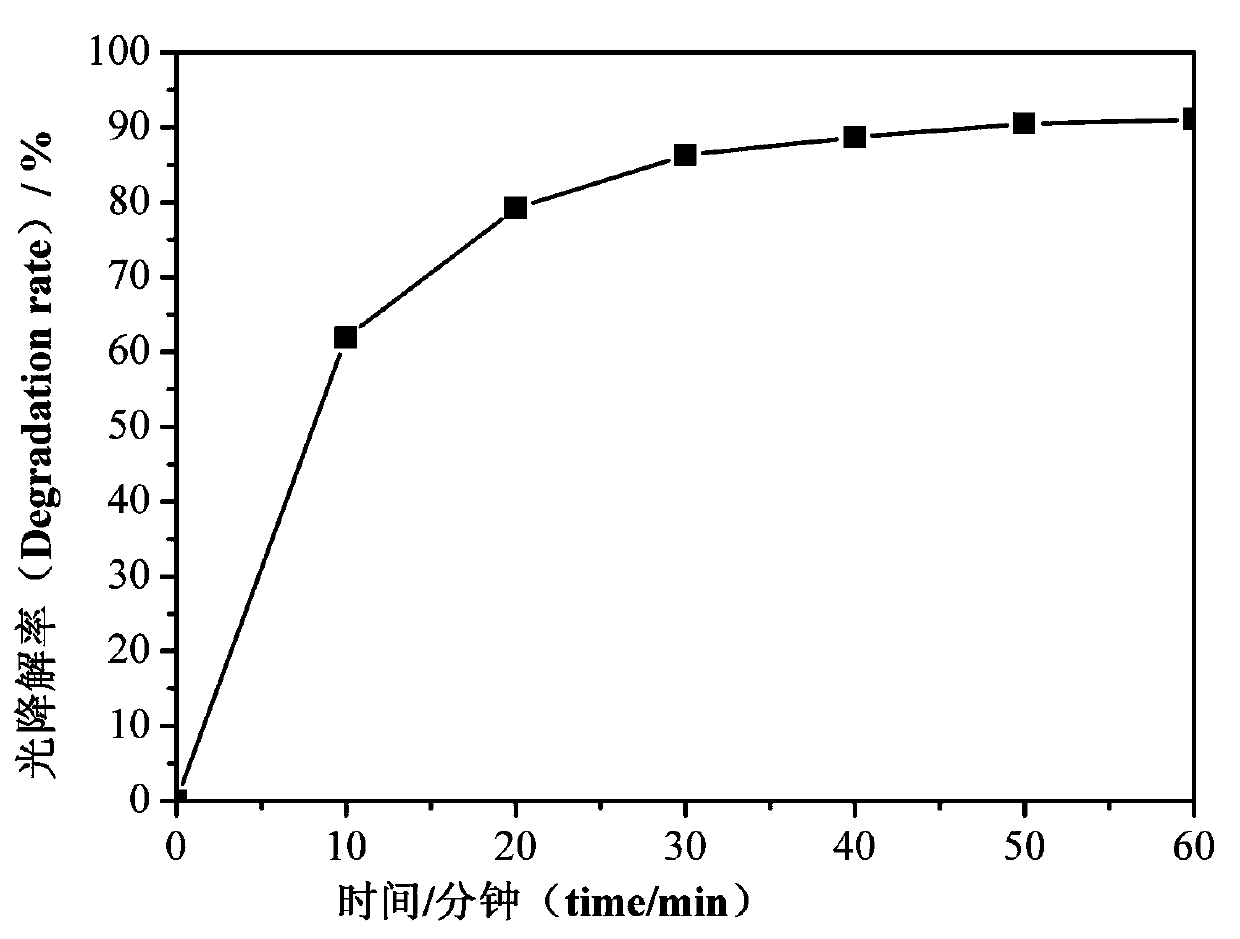

[0030] A kind of bismuth trioxide (Bi 2 O 3 ) The preparation method of microspheres is carried out according to the following steps:

[0031] A. Weigh 0.5 mmoL of Bi(NO 3 ) 3 · 5H 2 O, dissolve in 5 mL ethylene glycol solution under ultrasonic stirring to form bismuth nitrate solution;

[0032] B. Weigh 0.1 mmoL In(NO 3 ) 3 · 4.5H 2 O and 0.1mmoL urea, magnetically stirred to dissolve them in 5 mL of absolute ethanol solution to form a mixed solution of indium nitrate and urea;

[0033] C. Add the solution of step B to the solution of step A, and then magnetically stir for 30 min;

[0034] D. Transfer the mixed system obtained in step C to a reaction kettle lined with polytetrafluoroethylene, raise the temperature to 180°C for 24 hours, and cool it naturally to obtain a solvothermal product;

[0035] E. Centrifuge the solvothermal product obtained in step D, wash it with deionized water and absolute ethanol three times, and dry the product after centrifugation in air at 60°C for 6 ho...

Embodiment 2

[0044] A kind of bismuth trioxide (Bi 2 O 3 ) The preparation method of microspheres is carried out according to the following steps:

[0045] A. Weigh out 5.0 mmoL of Bi(NO 3 ) 3 · 5H 2 O, dissolve in 30 mL ethylene glycol solution with ultrasonic stirring to form bismuth nitrate solution;

[0046] B. Weigh 1.0 mmoL In(NO 3 ) 3 · 4.5H 2 O and 1.0mmoL urea, magnetically stirred to dissolve them in 30 mL of absolute ethanol solution to form a mixed solution of indium nitrate and urea;

[0047] C. Add the solution of step B to the solution of step A, and then magnetically stir for 30 min;

[0048] D. Transfer the mixed system obtained in step C to a reaction kettle lined with polytetrafluoroethylene, raise the temperature to 100°C for 24 hours, and cool it naturally to obtain a solvothermal product;

[0049] E. Centrifuge the solvothermal product obtained in step D, wash it with deionized water and absolute ethanol three times, and dry the product after centrifugation in air at 60°C for...

Embodiment 3

[0052] A kind of bismuth trioxide (Bi 2 O 3 ) The preparation method of microspheres is carried out according to the following steps:

[0053] A. Weigh 0.5 mmoL of Bi(NO 3 ) 3 · 5H 2 O, dissolve in 5 mL ethylene glycol solution under ultrasonic stirring to form bismuth nitrate solution;

[0054] B. Weigh 0.1 mmoL In(NO 3 ) 3 · 4.5H 2 O and 1.0mmoL urea, magnetically stirred to dissolve them in 30 mL of absolute ethanol solution to form a mixed solution of indium nitrate and urea;

[0055] C. Add the solution of step B to the solution of step A, and then magnetically stir for 30 min;

[0056] D. Transfer the mixed system obtained in step C to a reaction kettle lined with polytetrafluoroethylene, raise the temperature to 120°C at a constant temperature for 24 hours, and cool it naturally to obtain a solvothermal product;

[0057] E. Centrifuge the solvothermal product obtained in step D, wash it with deionized water and absolute ethanol three times, and dry the product after centrifugat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com