Method for extracting wet algae oil

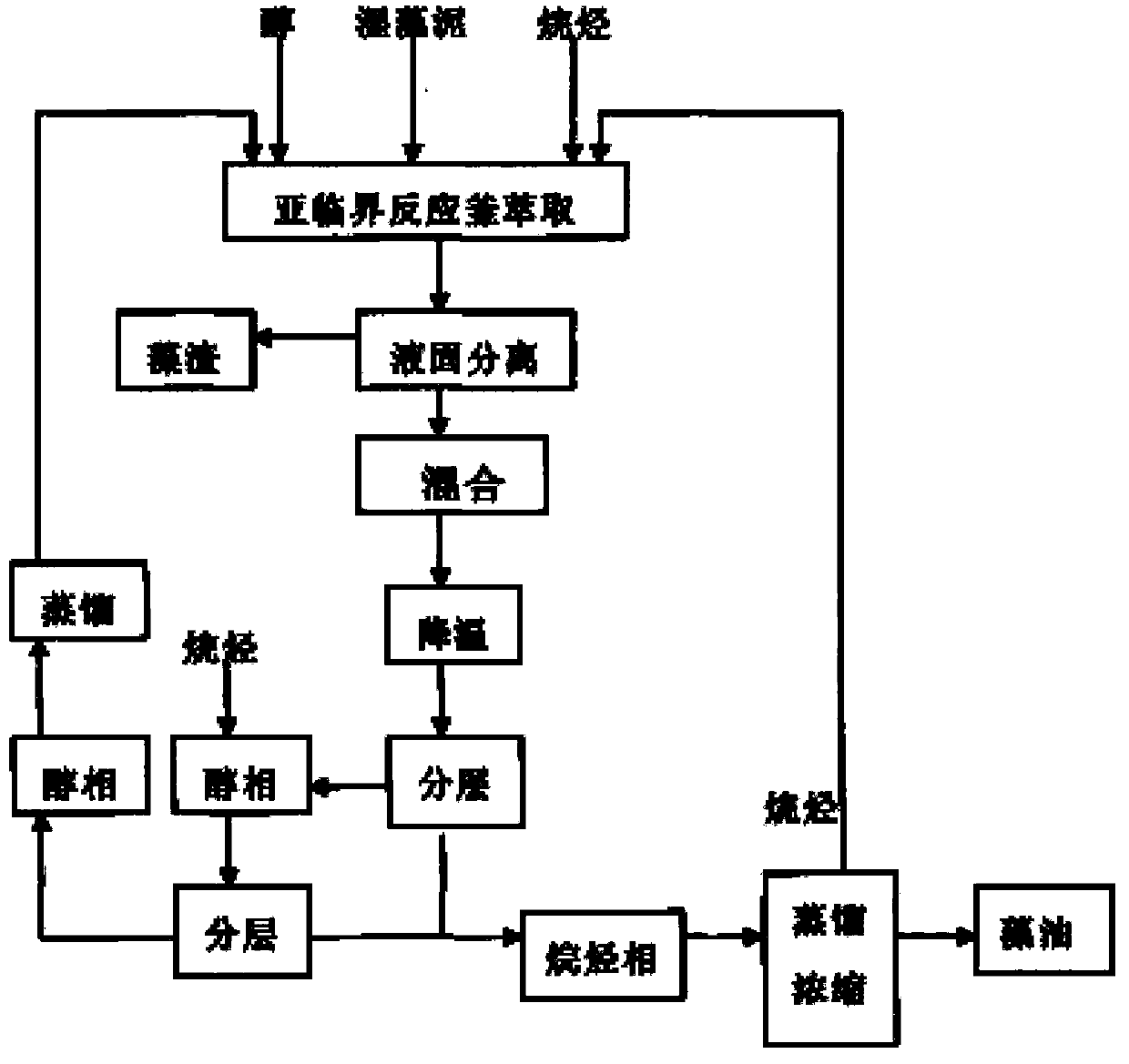

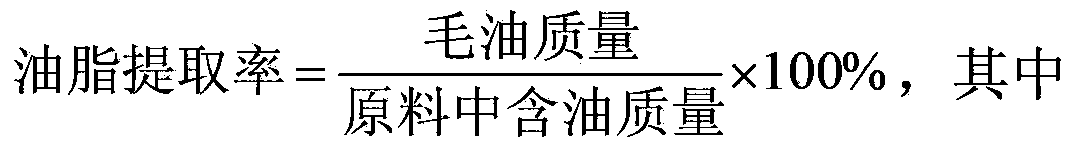

A technology for wet algae and oil, applied in the production of oil/fat and fat production, can solve the problems of complex oil extraction process, high difficulty in oil extraction wastewater treatment, low oil yield, etc., achieving easy recovery and separation, and reducing solvent costs. And the effect of difficult wastewater treatment and high oil extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

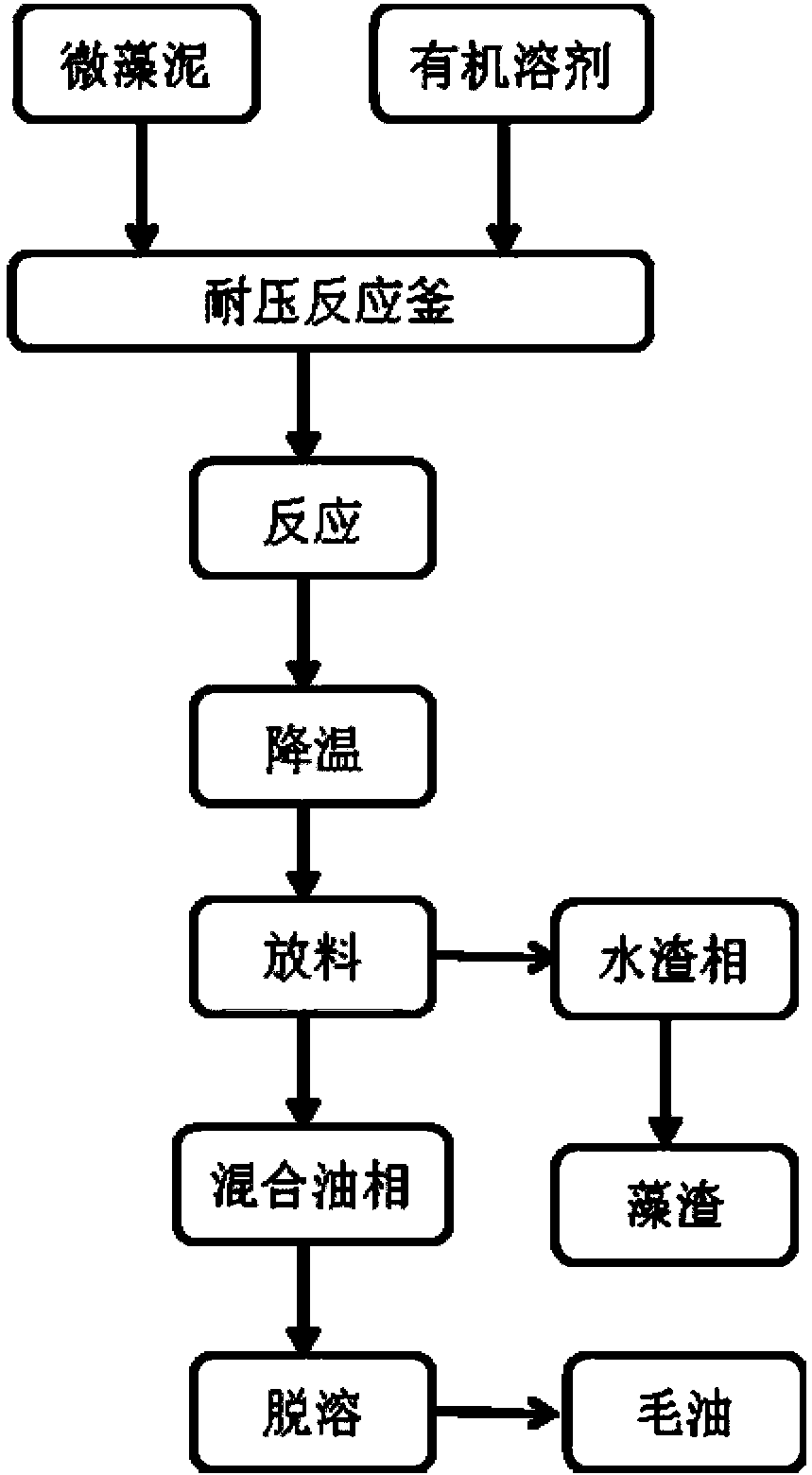

[0049] A method for extracting wet algal oil, said method comprising the steps of:

[0050] (1'''''') Mix the wet algae mud of oleaginous microalgae with a water-immiscible organic solvent, add the resulting mixture into a pressure-resistant reactor, seal the reactor, and wait until the reaction temperature is reached Then start to react, wherein the reaction temperature is 100~180°C, and the reaction time is 5~60 minutes;

[0051] (2'''''') Discharging after the reaction, collecting the upper mixed oil phase and the lower water slag phase respectively, and removing the solvent from the upper mixed oil phase to obtain crude oil.

[0052] Wherein, the water-immiscible organic solvent is selected from any one or a mixture of at least two of n-hexane, cyclohexane, n-heptane, petroleum ether or diethyl ether.

specific Embodiment approach 2

[0053] A method for extracting wet algal oil, said method comprising the steps of:

[0054] (1') Mix the wet algae mud of oil-producing microalgae with a water-immiscible organic solvent, add the obtained mixture into a pressure-resistant reactor, and pass inert gas into the reactor to replace the air in the reactor , the number of replacements is 2 to 3 times, then seal the reaction kettle, and start the reaction after reaching the reaction temperature, the reaction temperature is above the azeotropic point of the water-immiscible organic solvent and water;

[0055] (2') After the reaction is completed, the materials are discharged, the upper mixed oil phase and the lower water slag phase are collected respectively, and the upper mixed oil phase is evaporated to remove the solvent to obtain crude oil.

[0056] (3') Repeat step (1') and step (2') 1 to 3 times.

specific Embodiment approach 3

[0057] A method for extracting wet algal oil, said method comprising the steps of:

[0058] (1'') Mix the wet algae mud of oil-producing microalgae with a water-immiscible organic solvent, add the resulting mixture into a pressure-resistant reactor, and replace the reactor with an inert gas into the reactor Air, the number of replacements is 2 to 3 times. After the replacement, pass inert gas into the reactor to make the initial pressure of the reactor reach 0-1MPa (gauge pressure), seal the reactor, and start the reaction after reaching the reaction temperature. Above the azeotropic point of water-immiscible organic solvents and water;

[0059] (2'') After the reaction is completed, the materials are discharged, the upper mixed oil phase and the lower water residue phase are collected respectively, and the upper mixed oil phase is evaporated to remove the solvent to obtain crude oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com