Preparation method of gas sensor array for detecting medicinal-flavor liquor

A gas-sensing sensor and medicinal-flavor technology, which is applied in the field of gas-sensing sensors, can solve the problems of low organic gas sensitivity, increased sensor volume, low integration, etc., and achieves the effects of low cost, small impact and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

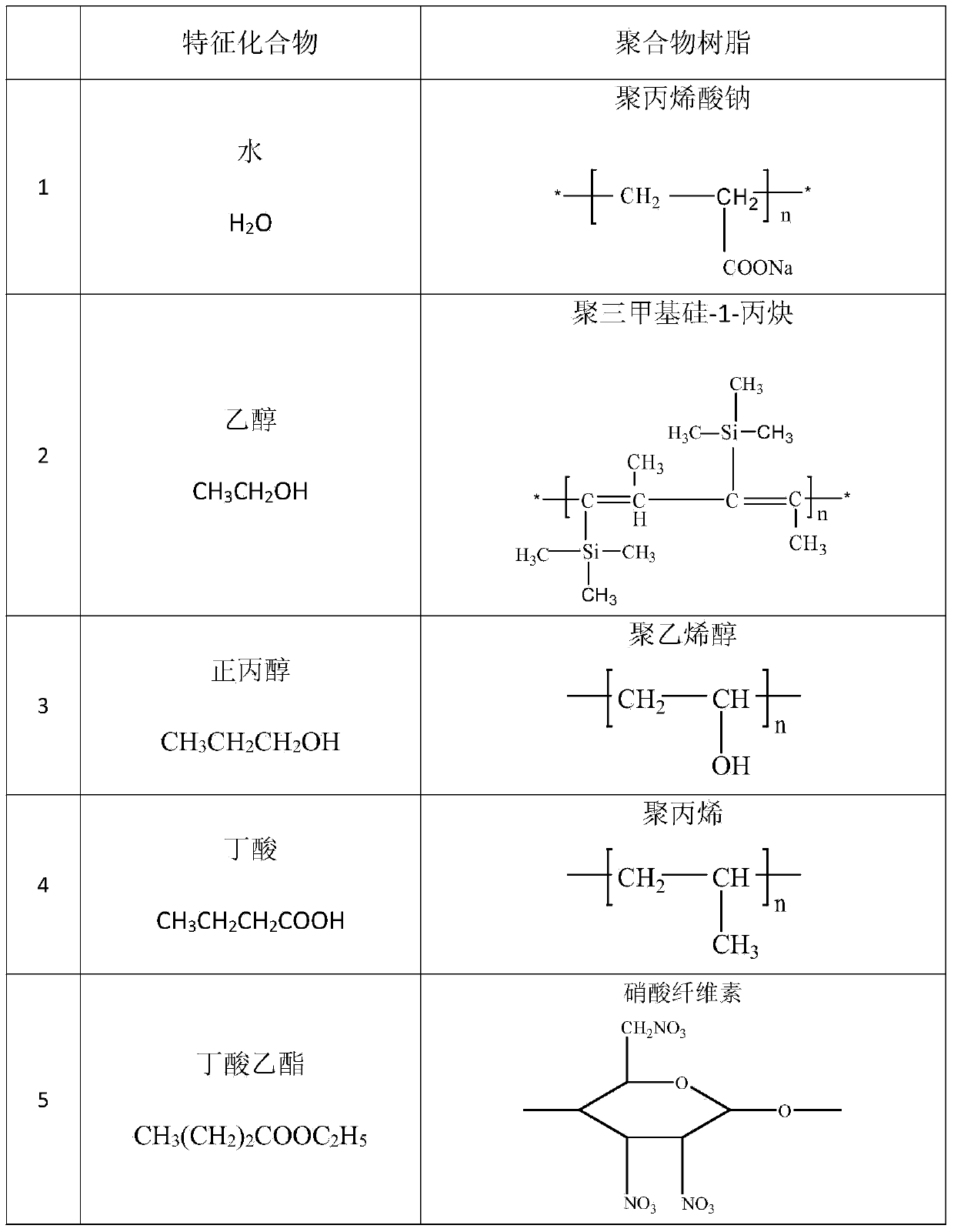

[0018] 1. Sodium polyacrylate used in the experiment was purchased from Aladdin Reagent Co., Ltd., with a molecular weight of 4 million; water was secondary deionized water; polytrimethylsilyl-1-propyne was purchased from Aladdin Reagent Co., Ltd., with a molecular weight of 500,000 ; Ethanol was purchased from Aladdin Reagent Co., Ltd., which is an AR grade pure reagent; polyvinyl alcohol was purchased from Bailingwei Reagent Co., Ltd., with a molecular weight of 20,000; n-propanol was purchased from Bailingwei Reagent Co., Ltd., with a purity of 98%; nylon-66 was purchased from Alpha Aisha Reagent Co., Ltd., the molecular weight is about 27000; butyric acid was purchased from Alpha Aisha Reagent Co., Ltd., with a purity of 99%; nitrocellulose was purchased from Bailingwei Reagent Co., Ltd.; ethyl butyrate was purchased from Bailingwei Reagent Co., Ltd. , with a purity of 99%.

[0019] 2. On the UNIVEX-300 vacuum coating machine, sodium polyacrylate, polytrimethylsilyl-1-prop...

Embodiment 2

[0033] 1. The reagents and polymer used are the same as those in Example 1.

[0034] 2. On the UNIVEX-300 vacuum coating machine, sodium polyacrylate, polytrimethylsilyl-1-propyne, polyvinyl alcohol, nylon-66, and nitrocellulose were vapor-deposited on a film with a diameter of 10mm and a thickness of 0.8mm. On a circular quartz substrate, the specific steps are as follows:

[0035] (1) Select a suitable substrate holder and place the quartz substrate and polyvinyl alcohol;

[0036] (2) Check the status of circulating cooling water, compressed air and high-purity nitrogen, and check the oil level of the mechanical pump and outlet oil mist filter;

[0037] (3) Turn the main power knob to the vertical position. After the self-test of the instrument is normal, close the bell cover, and pay attention to the position of the connecting rod on the left;

[0038] (4) Pass F 1 and F 5 Switch the display screen to the air extraction interface, start air extraction, and prohibit powe...

Embodiment 3

[0048] 1. The reagents and polymer used are the same as those in Example 1.

[0049] 2. Sodium polyacrylate, polytrimethylsilyl-1-propyne, polyvinyl alcohol, nylon-66, and nitrocellulose were vapor-deposited on the UNIVEX-300 vacuum coating machine at length × width = 10 × 10mm, thickness On a square quartz substrate of 1 mm, the specific steps are as follows:

[0050] (1) Select a suitable substrate holder and place the quartz substrate and polyvinyl alcohol;

[0051] (2) Check the status of circulating cooling water, compressed air and high-purity nitrogen, and check the oil level of the mechanical pump and outlet oil mist filter;

[0052] (3) Turn the main power knob to the vertical position. After the self-test of the instrument is normal, close the bell cover, and pay attention to the position of the connecting rod on the left;

[0053] (4) Pass F 1 and F 5 Switch the display screen to the air extraction interface, start air extraction, and prohibit power failure afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com