Method for efficiently extracting mung bean alpha-amylase inhibitor

An amylase inhibitor and mung bean technology, which is applied in the extraction field of mung bean alpha-amylase inhibitor, can solve the problems of centrifugal separation operation obstacle, reduce the biological activity of the product, increase the viscosity of the solution, etc. Development prospects, easy operation and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

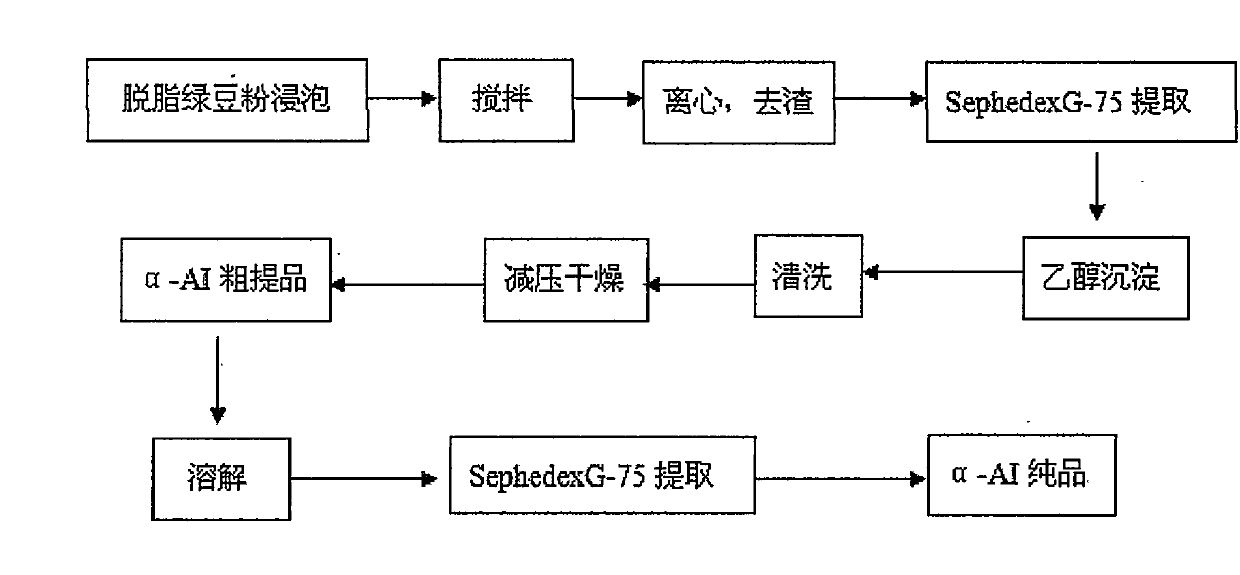

Method used

Image

Examples

Embodiment 1

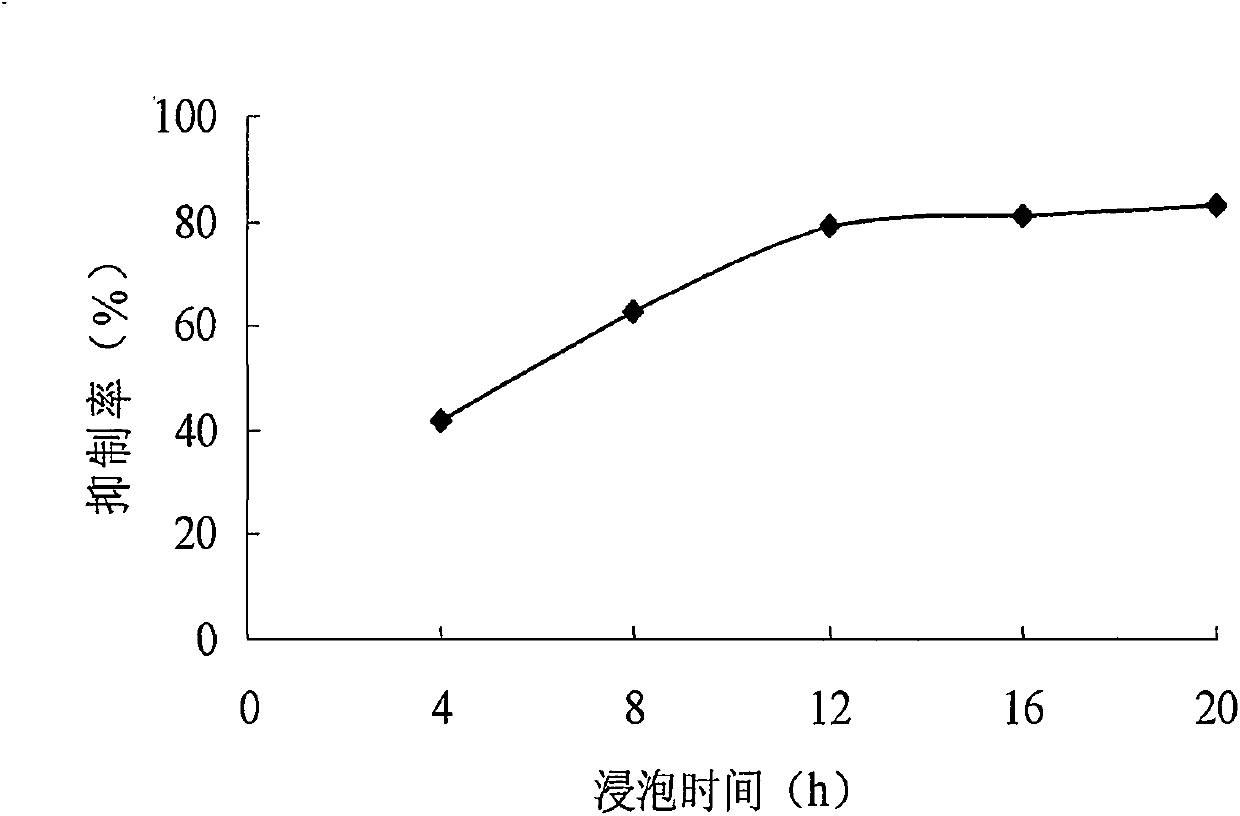

[0039] Soak 5×0.1kg of defatted mung bean flour at 40°C for 4h, 8h, 12h, 16h, and 20h respectively, and then use a high-speed universal grinder to grind them into powders below 100 mesh. After stirring, centrifuge at 12,000g at 4°C for 30min to remove slag ;

[0040] Gel column SephedexG-75 extraction: Use 0.02mol / L, pH 4.0 HAc-NaAc buffer to equilibrate the gel column, then add the supernatant obtained after the previous step of centrifugation into HAc-NaAc buffer to a final concentration of 0.02 mol / L, load the sample at a flow rate of 0.5mL / min, then elute and extract with 0.02mol / L, pH 4.0 HAc-NaAc buffer, collect protein peaks and measure amylase inhibitory activity tube by tube, collect activity peaks and elute solution, mixed with ethanol pre-placed at -20°C according to the volume ratio of 1:1, and precipitated at -20°C. The extraction time is the time for the first Sephedex G-75 extraction to collect the active peak eluate and ethanol precipitation at -20°C. , is 1.5...

Embodiment 2

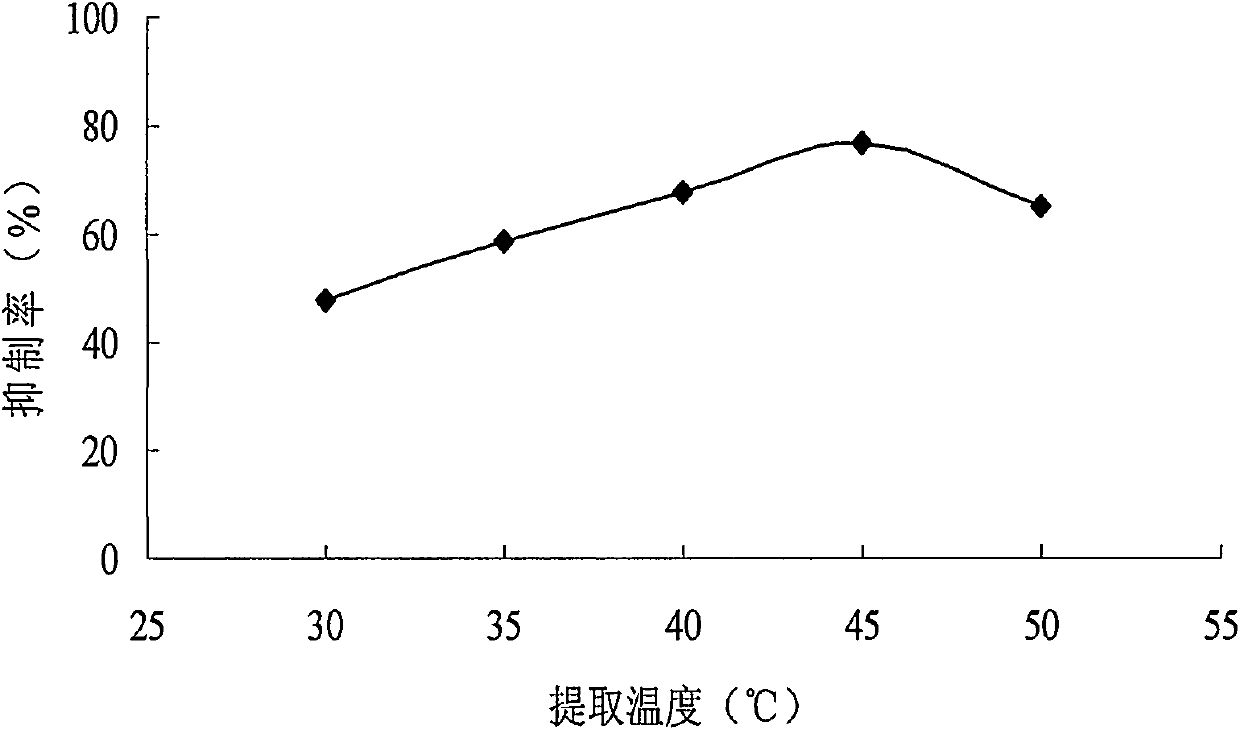

[0045] Soak 5×0.1kg of defatted mung bean powder in 30°C, 35°C, 40°C, 45°C, 50°C for 12 hours, and then use a high-speed universal grinder to make a powder with a mesh size of less than 100. After stirring, 12000g, 4°C , centrifuged for 30min to remove slag;

[0046] Gel column SephedexG-75 extraction: Use 0.02mol / L, pH 4.0 HAc-NaAc buffer to equilibrate the gel column, then divide the supernatant obtained after the previous step of centrifugation into five equal parts, add HAc-NaAc buffer to each solution to a final concentration of 0.02mol / L, loaded at a flow rate of 0.5mL / min, and then eluted with 0.02mol / L, HAc-NaAc buffer solution with a pH of 4.0 to collect protein peaks and measure amylase inhibition tube by tube. The active peak eluate was collected, mixed with ethanol pre-placed at -20°C in a volume ratio of 1:1, precipitated at -20°C, and the extraction time was the first Sephedex G-75 extraction to collect the active peak eluate and The time for ethanol precipitati...

Embodiment 3

[0051] Soak 5×0.1kg of defatted mung bean flour at 40°C for 12 hours, then use a high-speed universal grinder to make a mill powder with a mesh size below 100 mesh, and centrifuge at 12,000g at 4°C for 30 minutes to remove slag after stirring;

[0052] Gel column SephedexG-75 extraction: Use 0.02mol / L, pH 4.0 HAc-NaAc buffer to equilibrate the gel column, then divide the supernatant obtained after the previous step of centrifugation into five equal parts, add HAc-NaAc buffer to each solution to a final concentration of 0.02mol / L, loaded at a flow rate of 0.5mL / min, and then eluted with 0.02mol / L, HAc-NaAc buffer solution with a pH of 4.0 to collect protein peaks and measure amylase inhibition tube by tube. The active peak eluate was collected, mixed with ethanol pre-placed at -20°C in a volume ratio of 1:1, precipitated at -20°C, and the extraction time was the first Sephedex G-75 extraction to collect the active peak eluate and The time for ethanol precipitation at -20°C is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com